Solid heat carrier rapid pyrolysis method and apparatus

A solid heat carrier, pyrolysis technology, applied in the direction of direct heating dry distillation, petroleum industry, coke oven, etc., can solve the problems of lack of adjustment means, large pressure difference, influence of hot ash distribution valve operation, etc., to achieve good fuel adaptability , temperature controllable, enhance the effect of balance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

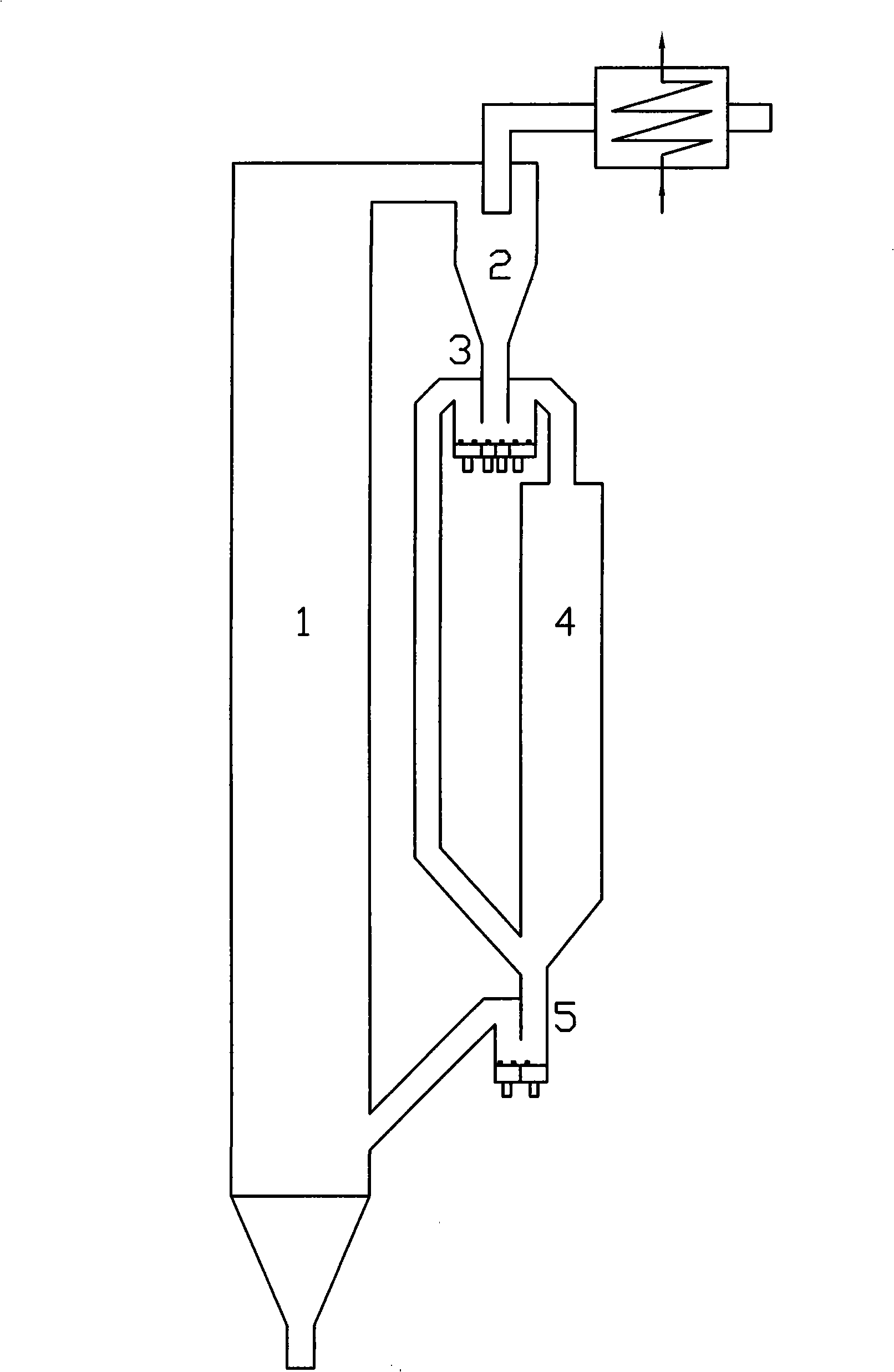

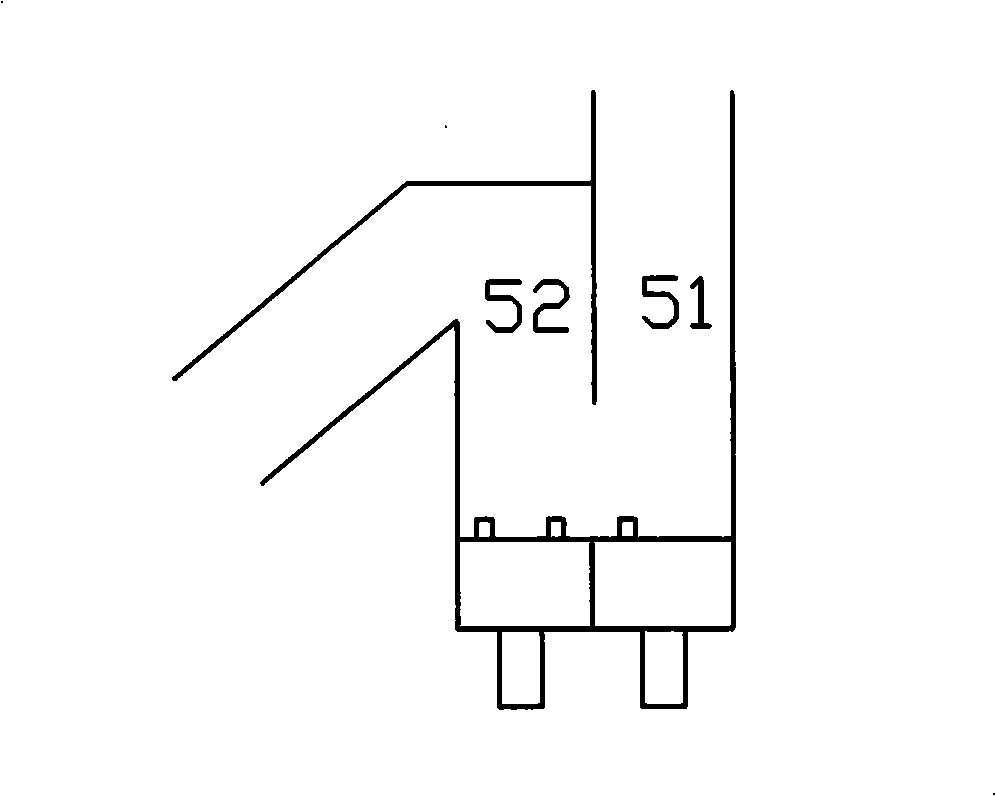

[0034] like figure 1 As shown, the fuel is burned in the circulating fluidized bed combustion chamber 1, and the high-temperature circulating ash in the flue gas captured by the cyclone separator 2 is divided into two parts by the pneumatically controlled hot ash distributor 3, and one part enters the moving bed as a solid heat carrier The pyrolysis chamber 4 provides heat for the pyrolysis of the fuel in the pyrolysis chamber 4, and the pyrolysis gas is drawn from the pyrolysis chamber 4; the other part of the circulating ash does not enter the pyrolysis chamber 4, and is discharged from the bottom of the pyrolysis chamber 4 with the semi-coke and The circulating ash returns to the combustion chamber 1 through the differential bed return device 5 together.

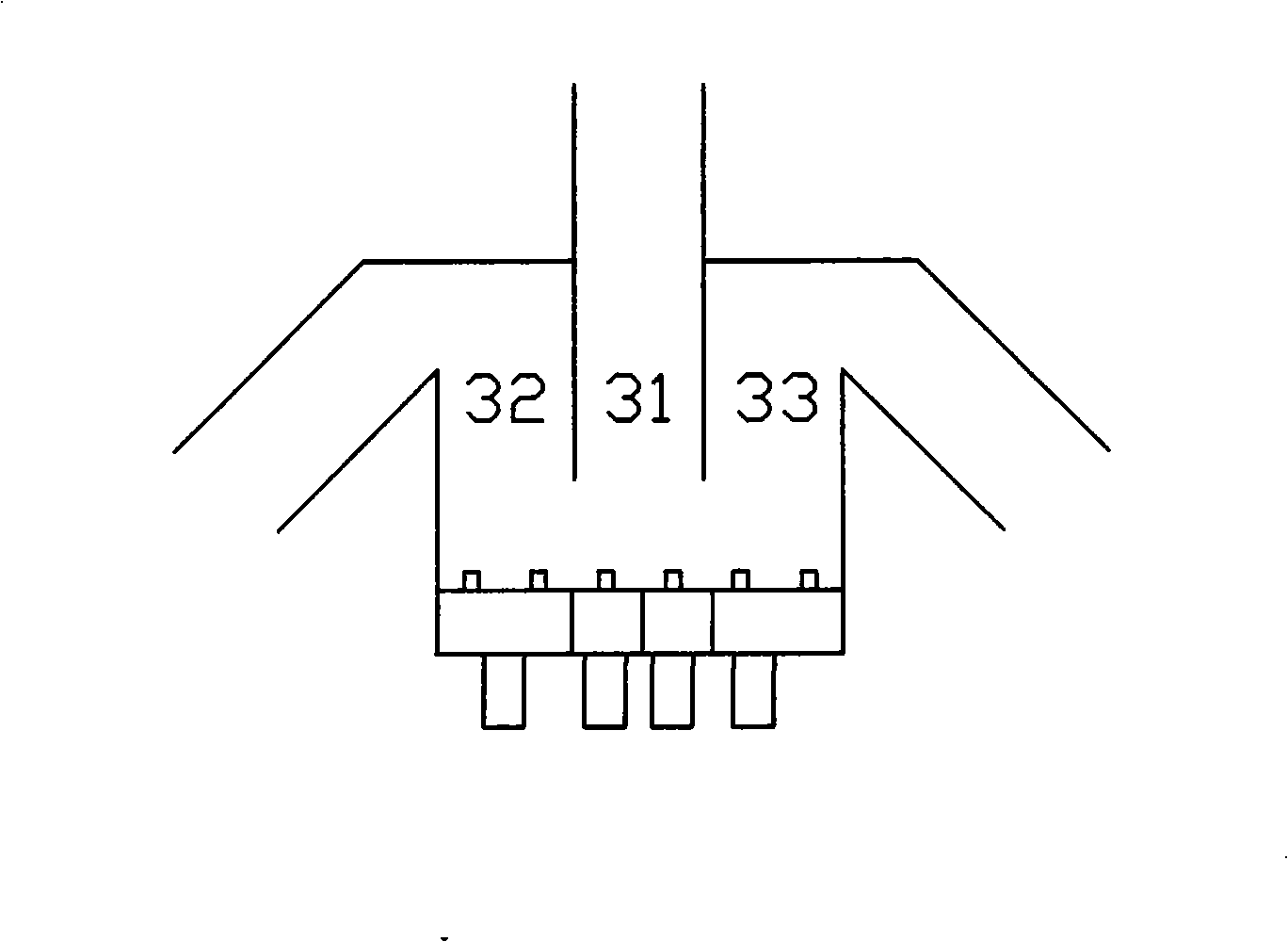

[0035] The solid heat carrier rapid pyrolysis device of the present invention includes: a circulating fluidized bed combustion chamber 1 connected in sequence, a cyclone separator 2, a pneumatically controlled hot ash dis...

Embodiment 2

[0037] like Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that a hot ash cooler 6 is added.

[0038] The fuel is burned in the circulating fluidized bed combustion chamber 1, and the high-temperature circulating ash in the flue gas captured by the cyclone separator 2 is divided into two parts by the pneumatically controlled hot ash distributor 3, and one part enters the moving bed pyrolysis chamber as a solid heat carrier 4. Provide heat for fuel pyrolysis, and the other part of the circulating ash does not enter the pyrolysis chamber 4. After the heat is released by the hot ash cooler 6, it is fed back through the differential bed together with the semi-coke and circulating ash discharged from the bottom of the pyrolysis chamber 4. The device 5 returns to the combustion chamber 1 .

[0039]The solid heat carrier rapid pyrolysis device provided by the present invention includes: a circulating fluidized bed combustion chamber 1 connected in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com