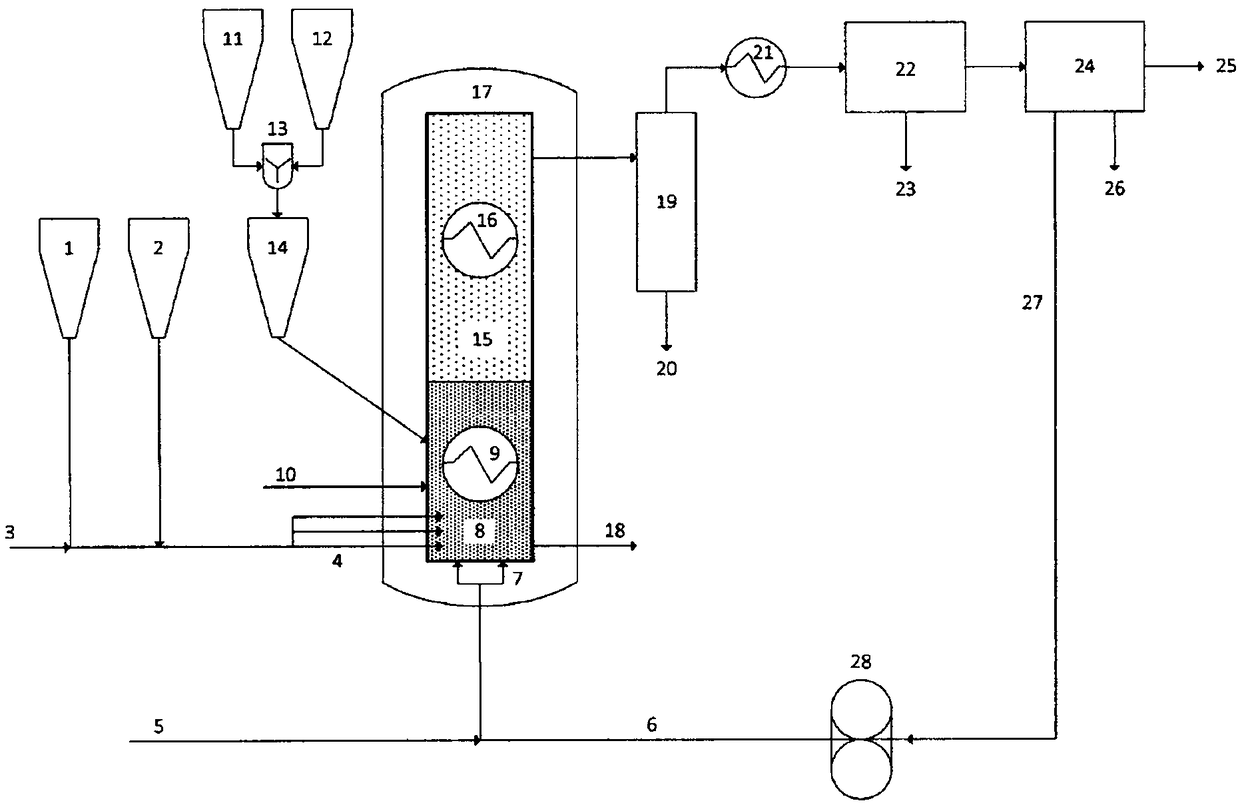

System and method for oxygen carrier assisted oxy-fired fluidized bed combustion

An oxygen carrier and combustion chamber technology, applied in fluidized bed combustion equipment, combustion methods, solid fuel combustion, etc., can solve problems such as power cost barriers and achieve the effect of low fluidization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0079]

[0080] With regard to oxygen carriers, it is preferred that the reaction upon reducing them is endothermic.

[0081] In another preferred embodiment, the oxygen carrier is abrasion resistant.

[0082]In another preferred embodiment, the oxygen carrier is resistant to poisoning by fuel components, including ash and sulfur species.

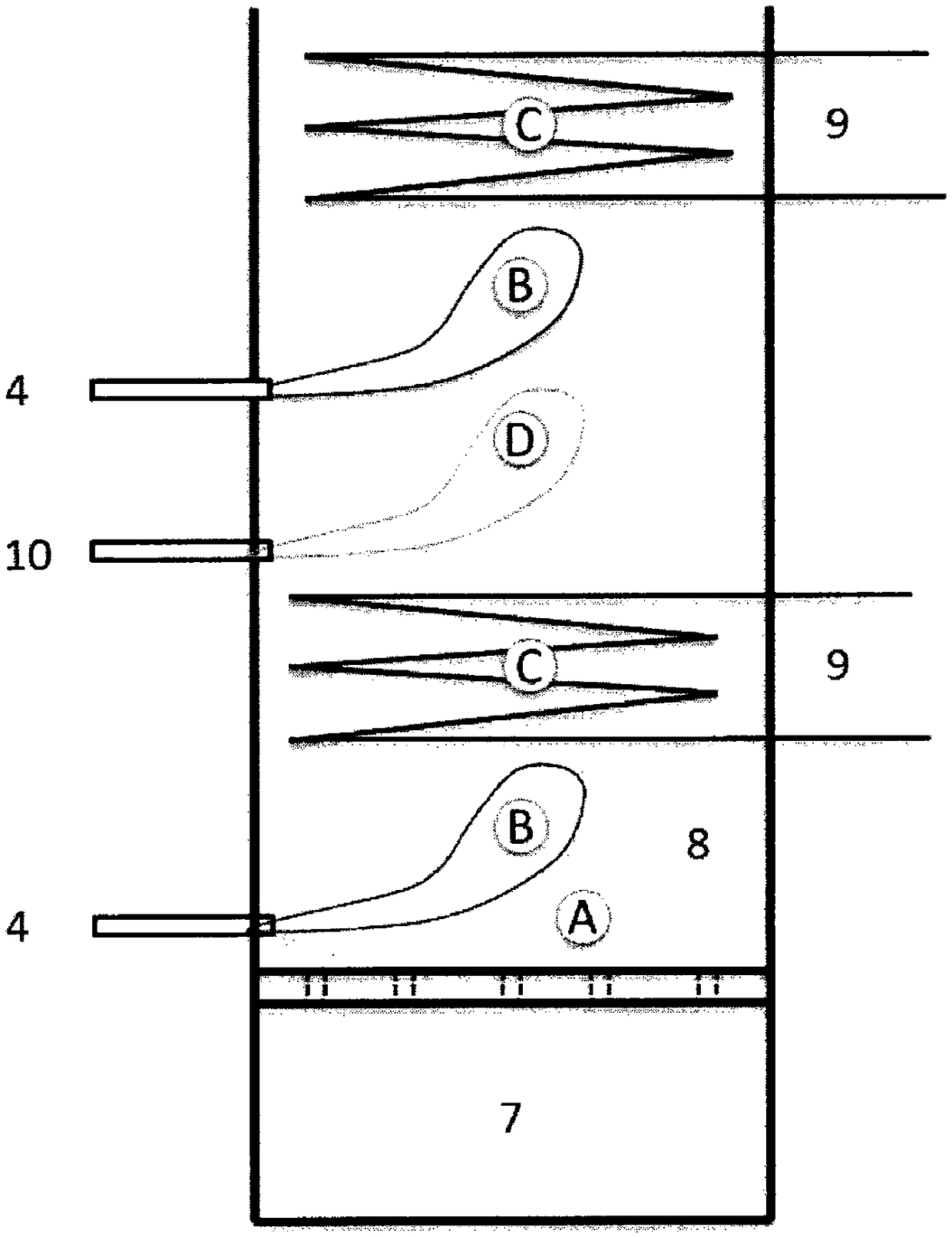

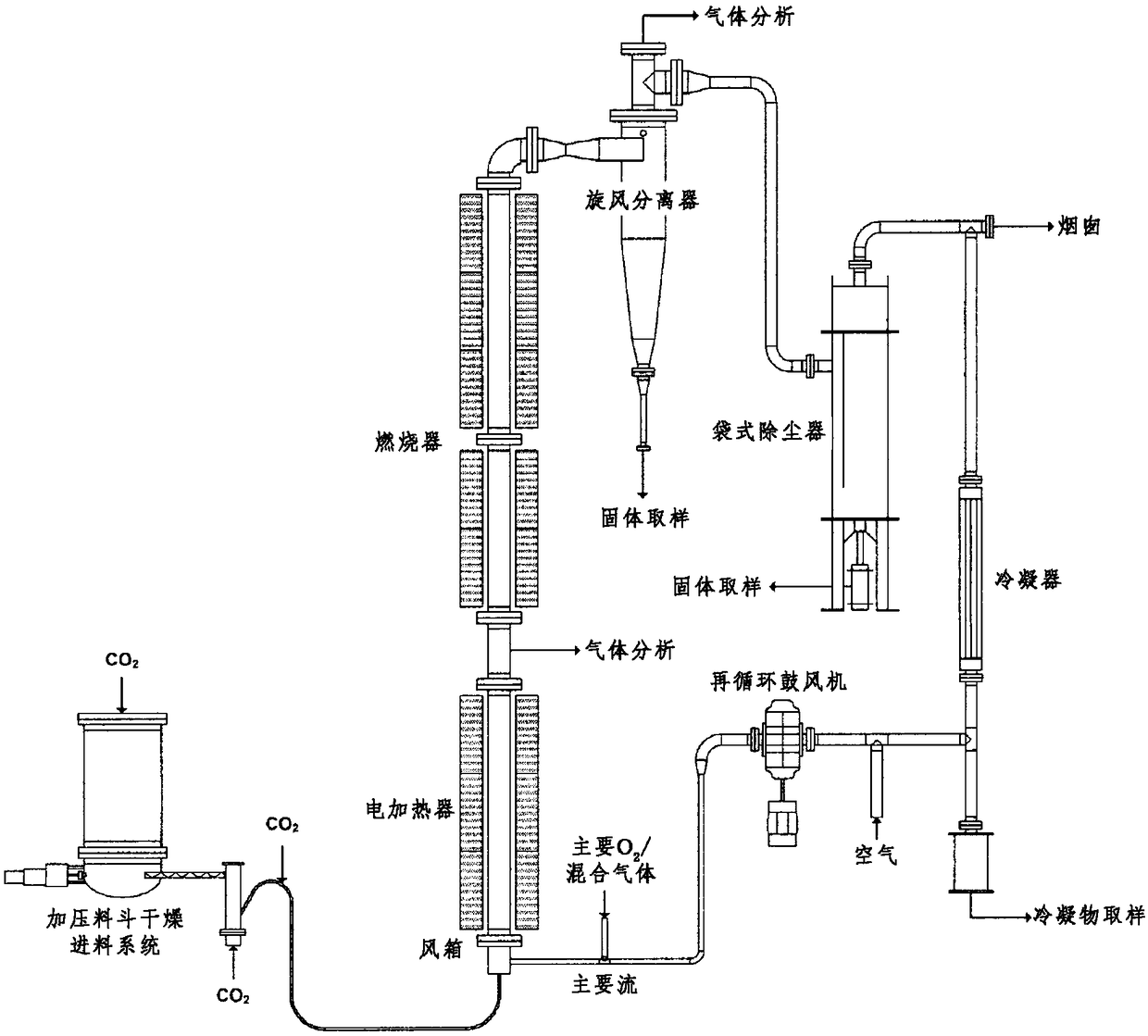

[0083] Under atmospheric pressure or high pressure, fuel and desulfurization adsorbent are injected into the oxy-combustion fluidized bed combustor using motive gas or buffer gas, which transports fuel and desulfurization adsorption through multiple injectors in the form of air action agent. Motive gas or buffer gas can be in CO 2 Purified carbon dioxide produced in the treatment plant.

[0084] At atmospheric or elevated pressure, oxygen (O 2 ) and mainly carbon dioxide (CO 2 ) composed of recirculated flue gas combined. Will O 2 Mixing with recirculated flue gas is to avoid localized hot spots within the burner; injection of pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com