Method for gold extraction by chlorination technology capable of improving utilization ratio of calcium chloride

A technology of calcium chloride and utilization rate, applied in the direction of improving process efficiency, etc., can solve problems such as equipment corrosion, increase production cost, calcium ion waste, etc., and achieve the effect of solving equipment corrosion, improving production efficiency, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for extracting gold by chloride for improving the utilization rate of calcium chloride, comprising the following steps:

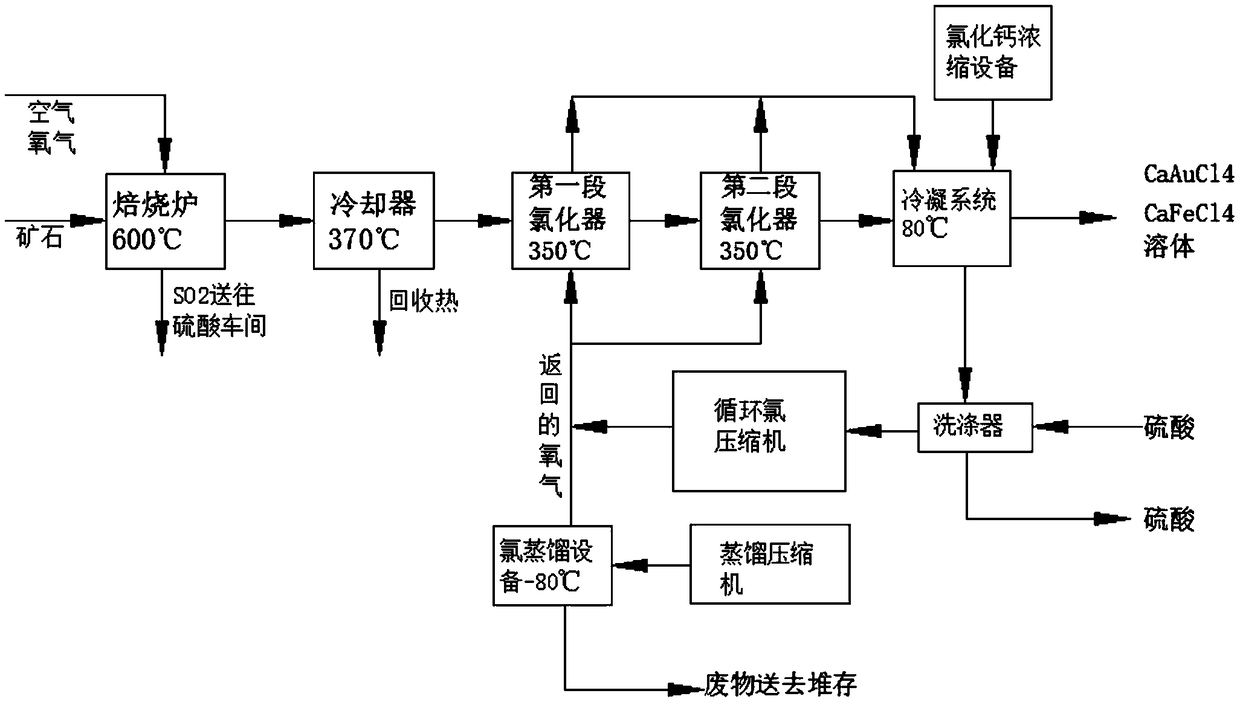

[0020] (1) The crushed ore and air oxygen are fed into the fluidized roaster, and the temperature in the roaster is maintained at 600°C, and the SO2 produced is sent to the sulfuric acid workshop;

[0021] (2) The ore roasted by the roaster is cooled by the cooler, and the temperature in the cooler is kept at 370°C, and then enters the first stage chlorinator and the second stage chlorinator, and goes to the first stage In the section chlorinator and the second section chlorinator, respectively feed recycled chlorine;

[0022] (3) The gas released from the first stage chlorinator and the second stage chlorinator enters the condensation system formed by the condensation chamber, and the calcium chloride concentrated in the condensation system contacts and reacts with the calcium chloride concentration equipment to generate CaAuCl4 and CaFeCl...

Embodiment 2

[0030] A method for extracting gold by chloride for improving the utilization rate of calcium chloride, comprising the following steps:

[0031] (1) The crushed ore and air oxygen are fed into the fluidized roaster, and the temperature in the roaster is maintained at 600°C, and the SO2 produced is sent to the sulfuric acid workshop;

[0032] (2) The ore roasted by the roaster is cooled by the cooler, and the temperature in the cooler is kept at 370°C, and then enters the first stage chlorinator and the second stage chlorinator, and goes to the first stage In the section chlorinator and the second section chlorinator, respectively feed recycled chlorine;

[0033] (3) The gas released from the first stage chlorinator and the second stage chlorinator enters the condensation system formed by the condensation chamber, and the calcium chloride concentrated in the condensation system contacts and reacts with the calcium chloride concentration equipment to generate CaAuCl4 and CaFeCl...

Embodiment 3

[0036] A method for extracting gold by chloride for improving the utilization rate of calcium chloride, comprising the following steps:

[0037] (1) The crushed ore and air oxygen are fed into the fluidized roaster, and the temperature in the roaster is maintained at 600°C, and the SO2 produced is sent to the sulfuric acid workshop;

[0038] (2) The ore roasted by the roaster is cooled by the cooler, and the temperature in the cooler is kept at 370°C, and then enters the first stage chlorinator and the second stage chlorinator, and goes to the first stage In the section chlorinator and the second section chlorinator, respectively feed recycled chlorine;

[0039] (3) The gas released from the first stage chlorinator and the second stage chlorinator enters the condensation system formed by the condensation chamber, and the calcium chloride concentrated in the condensation system contacts and reacts with the calcium chloride concentration equipment to generate CaAuCl4 and CaFeCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com