Pressurized fluidized bed combustor with fuel cell carbon dioxide capture

A pressurized fluidized bed, fuel cell technology, applied in fluidized bed combustion equipment, fuel cells, electrochemical generators, etc., can solve problems such as increasing power costs, reduce capital costs, and improve the effects of existing technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

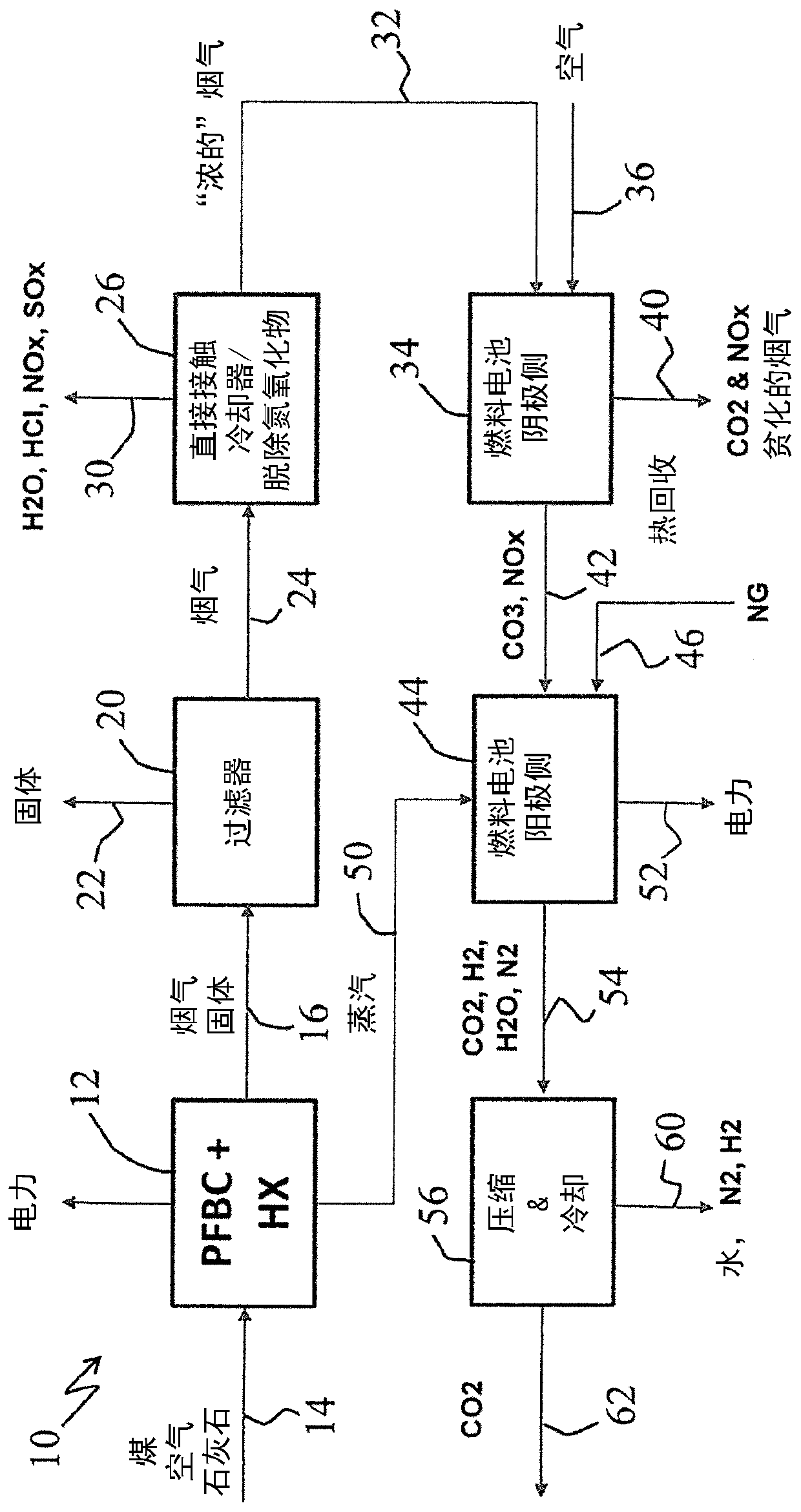

[0014] As detailed below, combining a pressurized fluidized bed combustor (PFBC) with a molten carbonate fuel cell (MCFC) is expected to provide a 2 A low-cost solution for captured power generation.

[0015] More specifically, the incorporation and use of the pressurized fluidized bed combustor (PFBC) proposed herein allows the combustion of solid fuels such as but not limited to coal, petroleum coke, biomass, etc. burn in the appliance. According to a preferred embodiment, the PFBC is approximately 1 / 3 the size of a conventional coal fired boiler at less than 1 / 2 the cost. Although an oxy-fired pressurized fluidized bed combustor, such as is currently under development, is contemplated for use in the practice of the present invention and is incorporated herein, in the following, specific reference will be made to the embodiment using an air-fired pressurized fluidized bed combustor The invention is further described, along with such air combustion operations, including and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com