A self-sustained synergistic reaction tank for photocatalysis conversion of pollutants and CO2 and a preparing method thereof

A technology of synergistic reaction and pollutants, applied in the direction of ion exchange water/sewage treatment, sterilization/microdynamic water/sewage treatment, energy wastewater treatment, etc., can solve the problems of imperfection, consumption of additional energy, high operating cost, etc., to achieve Eliminate the impact on the environment, promote conversion and power generation, and have a large effect on environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

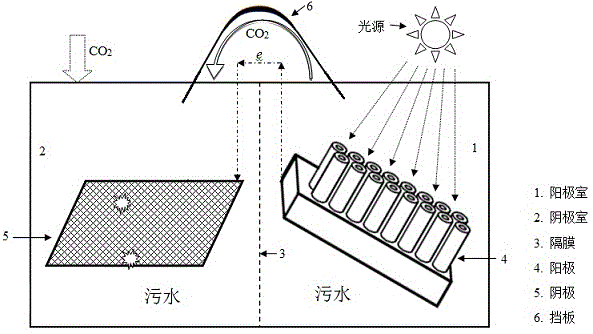

[0023] TiO2 with a tube diameter of 10-30 nm and a tube length of 20-30 μm was used 2 The nano-array tube is a photoelectrocatalytic material and acts as an anode. Put it obliquely into a phenol solution with a concentration of 0.1-5 mol / L to form an anode chamber. The inclination angle between the array tube and the horizontal plane is 50-60°. Add NaOH to the anode chamber Adjust the pH value of the solution, use Nafion117 cation exchange membrane as the diaphragm, and add saturated Na to the cathode chamber 2 CO 3 solution, the copper mesh as the cathode, and the anode as TiO 2 The distance between the array tube and the cathode copper grid is less than 30 cm, and the CO 2 Close to the cathode through the gas distribution plate, add a certain amount of 500 ~ 3000 m 2 / g of porous carbon enhanced CO 2 Absorption and dissolution, the transfer process is enhanced by stirring in the two chambers, and the anode TiO 2 The array tube is connected to the cathode copper grid to ...

Embodiment 2

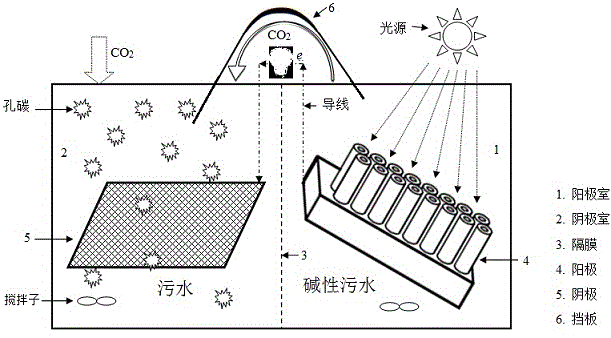

[0025] MoS with a particle size of 5–20 nm was impregnated 2 The powder is carried on the porous molecular sieve Ti—MCM-41, put into a titanium basket with quartz glass on one side as photocatalyst and anode, and put it obliquely into the printing and dyeing waste liquid to form the anode chamber, the quartz glass surface of the titanium basket and the The inclination angle of the horizontal plane is 10-60°. Add CaO to the anode chamber to adjust the pH value of the solution to be greater than 9. Anion exchange membranes are used as the diaphragm. Seawater is added to the cathode chamber, and graphite felt doped with Fe-doped nano-GaP is used as the cathode. 2 into the bottom of the cathode chamber, add 1000 ~ 2000 m 2 / g of porous carbon enhanced CO 2 The anode titanium basket and the cathode graphite felt are connected by wires to form an external circuit, the distance between the anode and the cathode is less than 50 cm, the load is a small fan, and a curved arc-shaped baf...

Embodiment 3

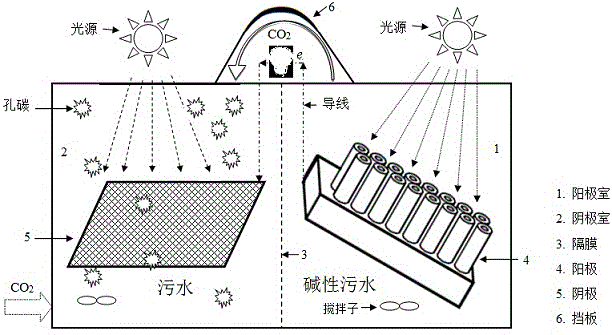

[0027] to the above Example 2 Simultaneously apply 100 ~ 200 W simulated sunlight to accelerate CO in the cathode chamber 2 conversion, such as image 3 Shown, add appropriate amount of NH to the cathode chamber 3 ·H 2 O consumes the photogenerated holes generated in the chamber, reduces the recombination of photogenerated holes and electrons, and strengthens the CO 2 For the electron reception of the electrode, the printing and dyeing waste liquid in the anode chamber is replaced with electroplating wastewater, and the other things remain unchanged. After adjusting the composition, concentration and pH value of the solutions on both sides, the composition of the cathode chamber product can be changed, which is formed by methane, CO, methanol, and formaldehyde.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com