Process for reducing impacts on LixFeyPzO4 caused by impurity elements in ferrophosphorus

A technology of impurity elements and phosphorus elements, applied in the field of purification and low-cost development of high-performance electrode materials LixFeyPzO4, can solve the problems of not using oxygen to react raw materials, high raw material and preparation costs, complex processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

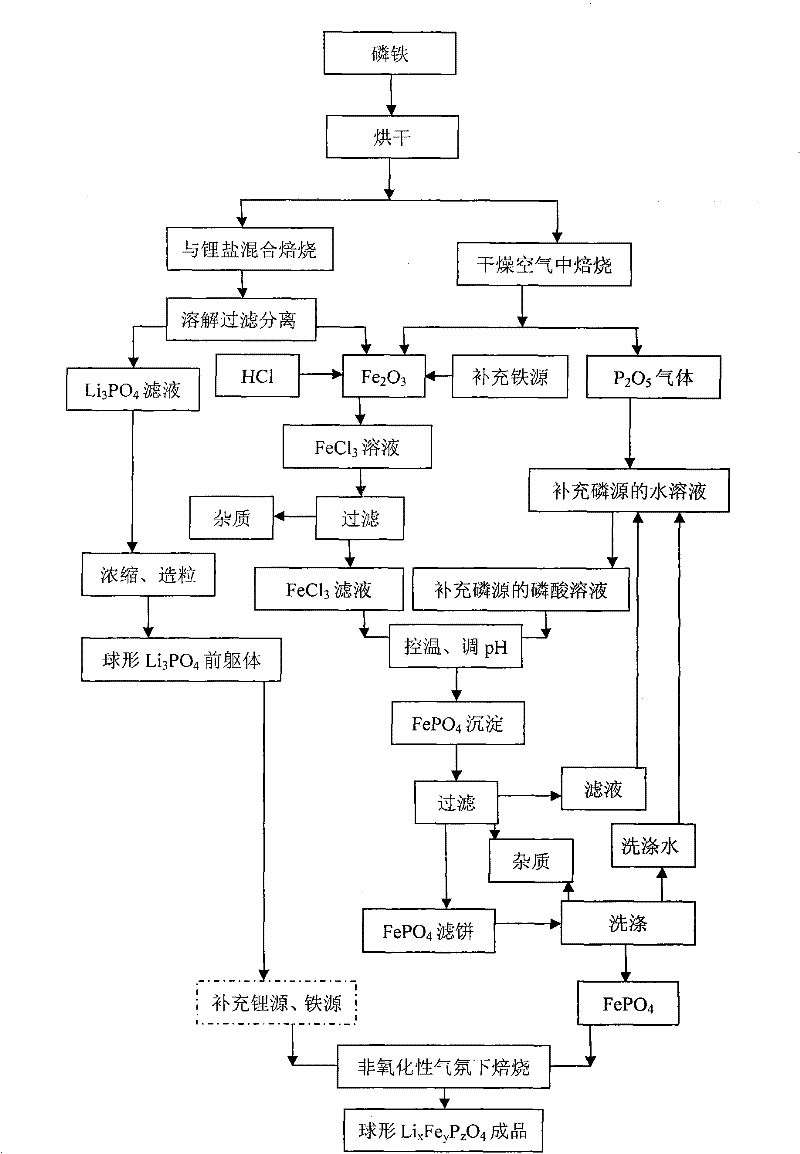

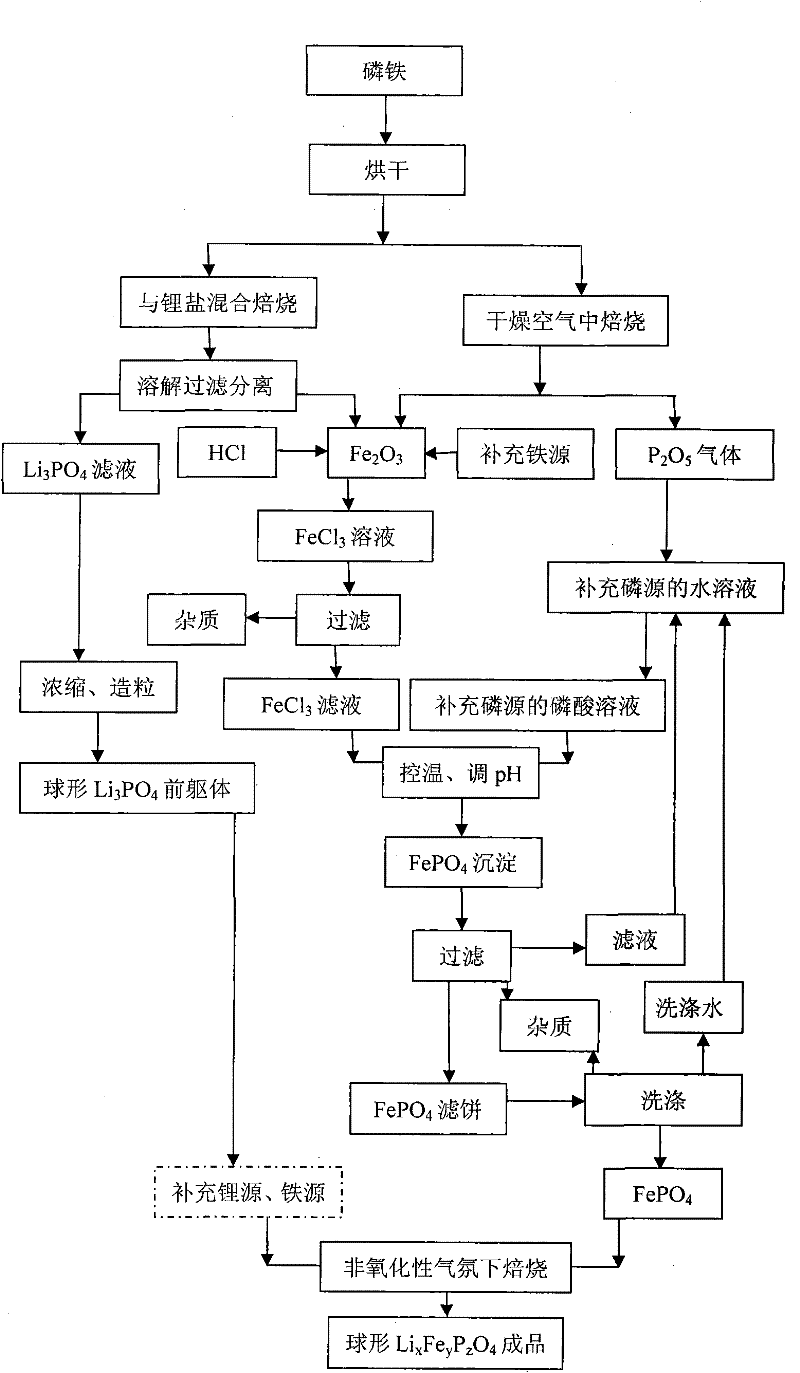

Method used

Image

Examples

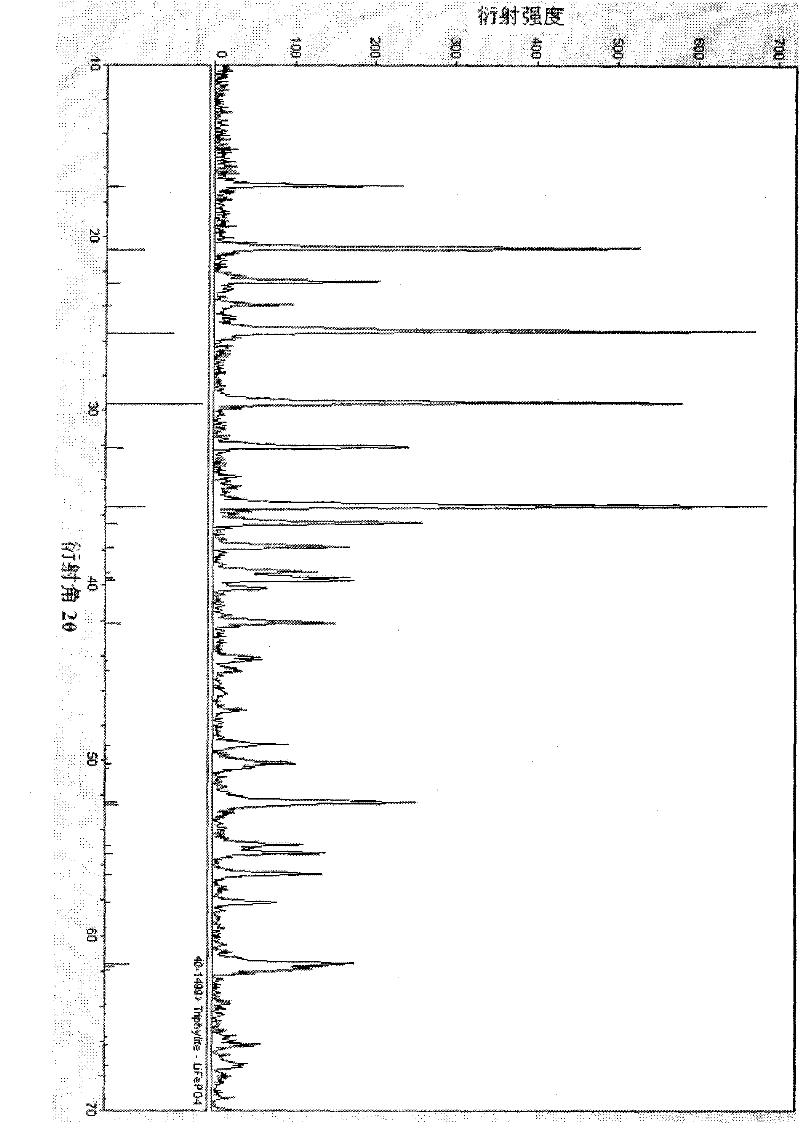

Embodiment 1

[0034] Fe 2 Preparation of LiFePO from P and lithium carbonate 4After dissolving ferrophosphorus with aqua regia, elemental analysis is carried out. The raw material of ferrophosphorus contains 67.7% Fe, 18.9% P, 6.3% Si, 2.1% Mn, 1.3% Ti, 1.2% V, 1.2% C, the remaining insoluble impurity content is 1.3%, according to the calculation, the composition of ferrophosphorus is approximately Fe 2 P, since C is burned off during the reaction, the real impurity elements are Si, Mn, Ti, V and insoluble impurities. It is worth noting that: according to literature reports, Si, Mn, Ti and V are beneficial to improve the 4 The electrochemical performance of the positive electrode material, and the impurity elements Si, Mn, Ti and V in the actual reaction process will affect the LiFePO 4 Perform in-situ self-doping. Here, it may be assumed that Si, Mn, Ti, V and insoluble impurities are the impurity elements to be removed in ferrophosphorus. According to their physical and chemical proper...

Embodiment 2

[0051] Preparation of LiFePO from iron phosphorus FeP and lithium hydroxide as raw materials 4 , after elemental analysis, the ferrophosphorus raw material contains 54.1% Fe, 29.8% P, 7.3% Si, 2.1% Mn, 1.5% Ti, 1.5% V, 2.2% C, and the remaining insoluble impurities are 1.5%, according to the calculation, the composition of ferrophosphorus is approximately FeP, since C is burned off during the reaction process, and 0.3% of other impurities are allowed to exist in battery grade raw materials, so the real impurity elements are Si, Mn, Ti, V and insoluble impurities, it is worth noting that according to literature reports Si, Mn, Ti and V are beneficial to improve LiFePO 4 The electrochemical performance of the positive electrode material, and the impurity elements Si, Mn, Ti and V in the actual reaction process will affect the LiFePO 4 Perform in-situ self-doping. Here, it may be assumed that Si, Mn, Ti, V and insoluble impurities are the impurity elements to be removed in ferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com