Temperature control method of fluidized bed reactor

A fluidized bed reactor, temperature control method technology, applied in the direction of temperature control, chemical instruments and methods, non-electrodynamic variable control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

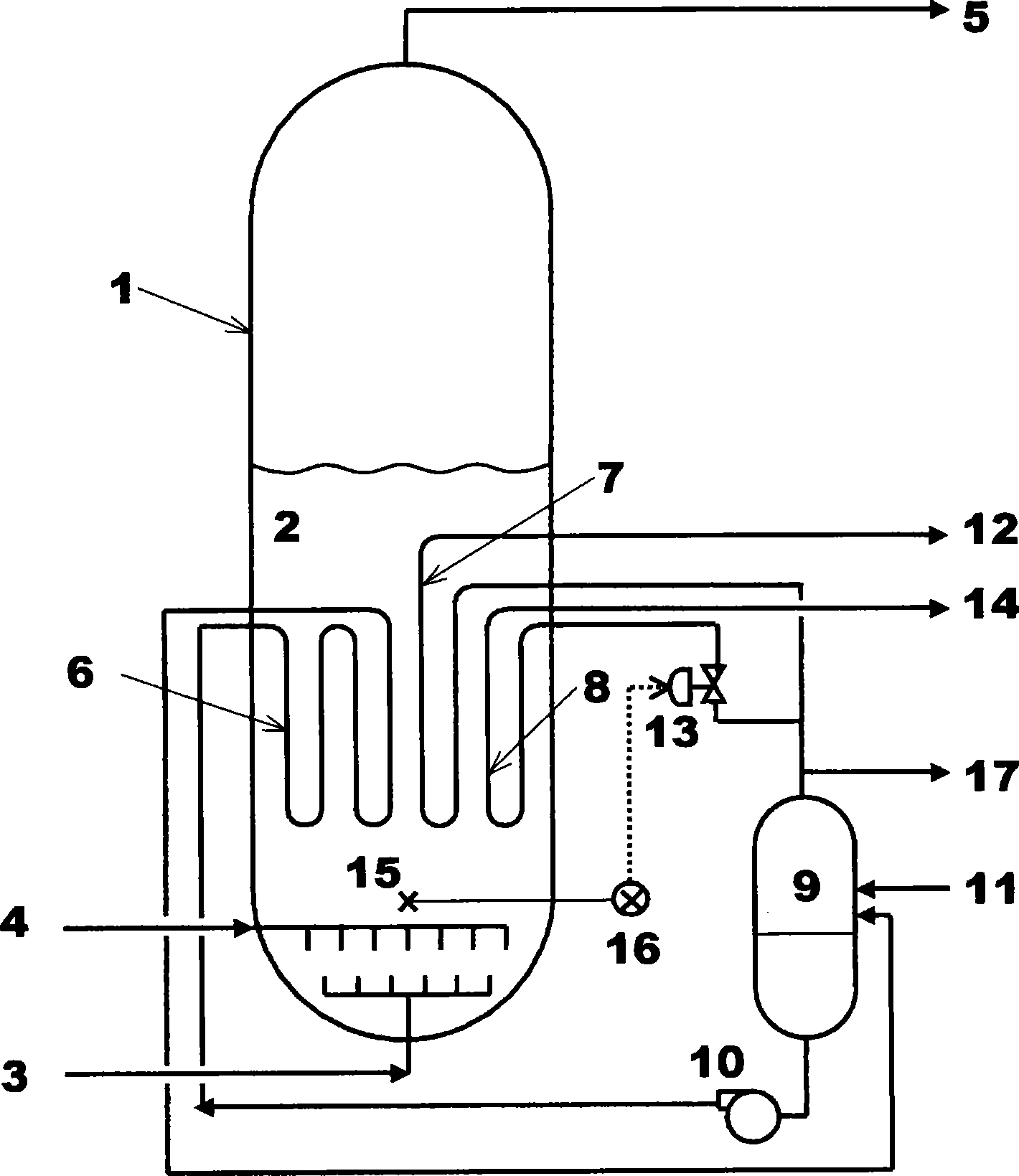

[0107] Xiang Ru figure 1 A fluidized bed reactor (1) with a diameter of 6.82 m in the form shown is filled with 80 tons of composite oxide catalysts, wherein the catalysts are composed of molybdenum, vanadium, antimony and niobium, with an average particle size of 50 μm and containing 12% Fine powder with a particle size of 44 μm or less. Supply air 45000Nm from the oxygen supply pipe (3) 3 / Hr, supply mixed propane 3000Nm from raw material supply pipe (4) 3 / Hr and ammonia 2700Nm 3 / Hr gas, mainly for the manufacture of acrylonitrile.

[0108] The fluidized bed (2) is equipped with conventional heat removal pipes (6) 30 series (the total length of the straight pipe part is 1250m), and the pipes use steel pipes with an outer diameter of 114.3mm specified in JIS G-3458 and corresponding to those specified in JIS B-2311. It is made of butt welded 180° large radius elbow. Supply 800 tons / Hr of water at 235°C to these conventional heat removal pipes (6) from the gas-liquid s...

Embodiment 2

[0114] In Example 1, without changing the set temperature and specified value, set the regulating valve so that the heat removal capacity of the heat removal pipe (8) can be adjusted from 100% of the adjustable range FS to 100% with an average change rate of 0.2FS / min. 0% change, or, change from 0% to 100%, automatic control operation is performed. At this time, the fluctuation range of the reactor temperature is 444-446°C, and it can be automatically controlled within the range of ±1°C relative to the set temperature.

[0115] In this embodiment, a K-type thermocouple is installed in the center of the fluidized bed as a temperature detector (15), and a temperature regulator (16) is used to convert the thermal electromotive force into a temperature signal for detection. In the temperature regulator (16), based on the difference between the detected temperature of the reactor and the set temperature, the DCS device CS3000 manufactured by Yokogawa Electronics Co., Ltd. is used t...

Embodiment 3

[0117] Perform PID calculation through DCS device, set control variables (P: proportional band, I: integral time, D: differential time), so as to make the heat removal capacity of heat removal pipe (8) from The ammoxidation reaction of propane was carried out in the same manner as in Example 1, except that the automatic control operation was performed by changing from 100% of the adjustable range FS to 0%, or from 0% to 100%. At this time, the fluctuation range of the reactor temperature is 444.5-445.5°C, which can be automatically controlled within the range of ±0.5°C relative to the set temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com