Automatic bottom cap mounting machine

A bottom cap machine and automatic technology, which is applied in the direction of conveyors, flanged bottle caps, mechanical conveyors, etc., can solve the problem that the efficiency of equipment capping cannot be greatly improved, and the bottom caps are not uniformly facing upward or uniformly downward , Incapable of effectively improving the efficiency of equipment capping, etc., to achieve the effect of good capping effect, good effect of capping, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

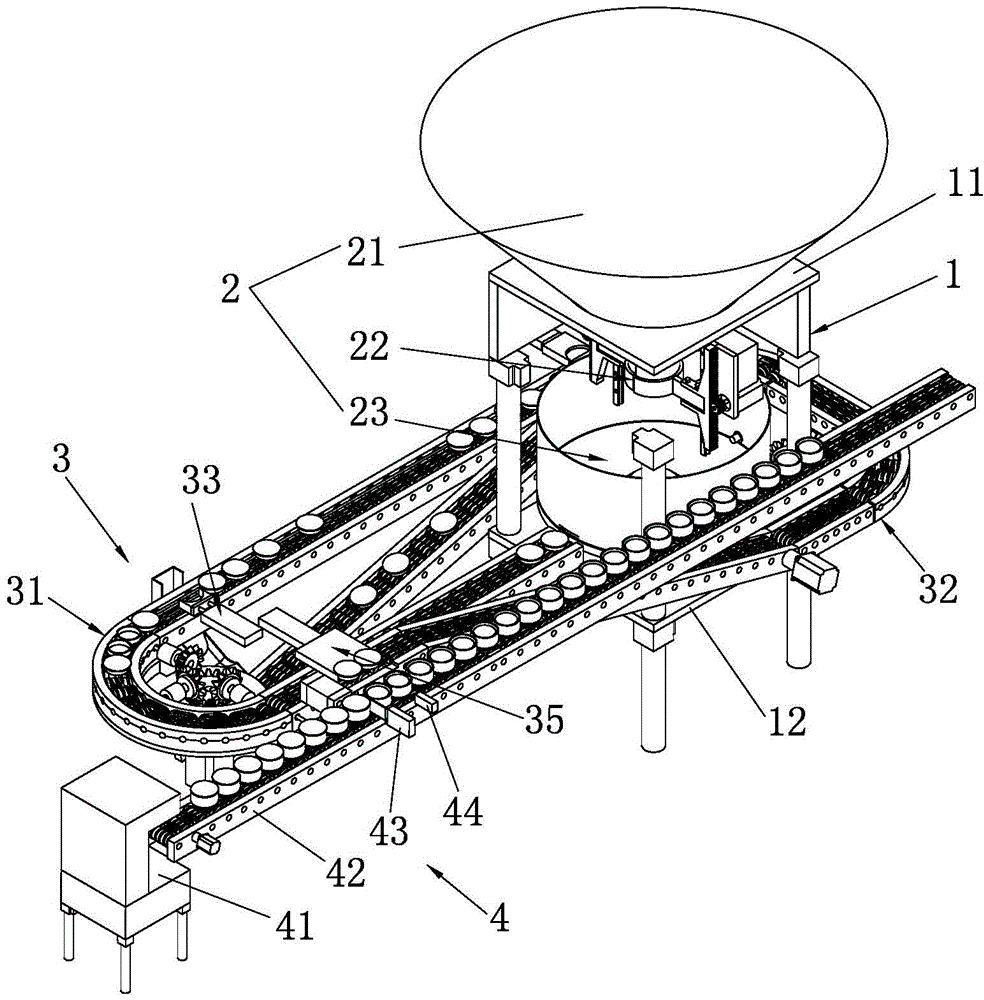

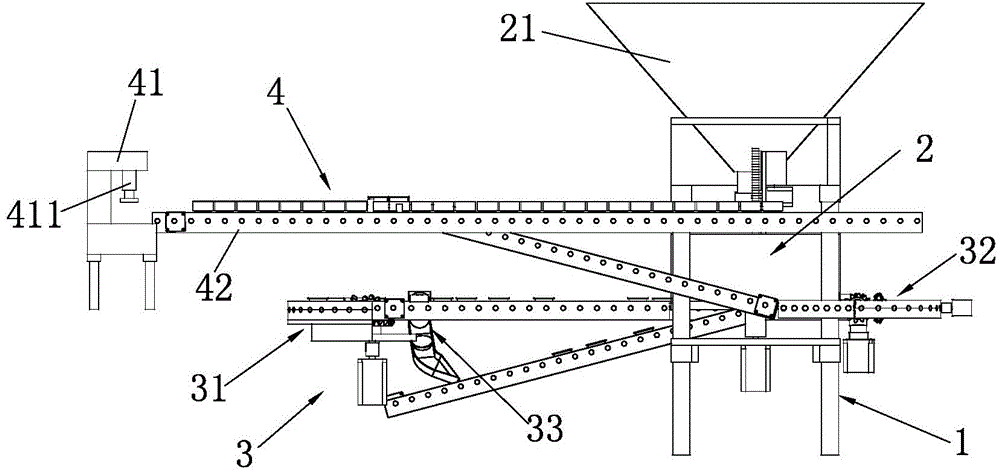

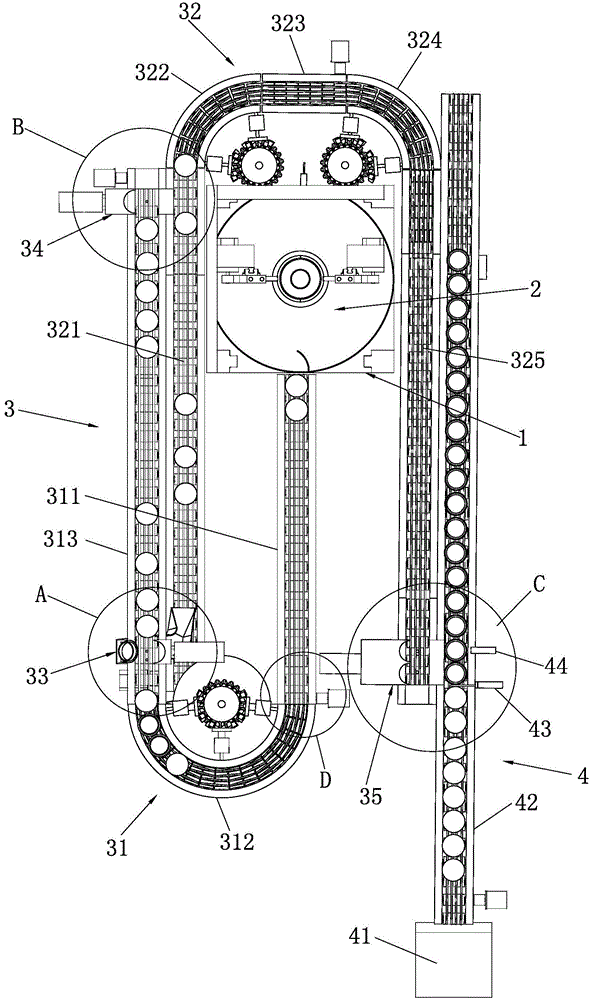

[0041] Such as Figure 1 to Figure 18 As shown, an automatic bottom cover machine includes a frame 1 and a control mechanism. The frame 1 is provided with a first flat plate 11 and a second flat plate 12 for installing components at intervals up and down. The mechanism (not shown in the accompanying drawings) is used to control the operation of the entire automatic bottom cover machine. The automatic bottom cover machine also includes a feeding device 2 for storing and automatically releasing the bottom cover 101, and a feeding device 2 for automatically arranging the bottom cover. 101 of the cap sorting device 3 and the capping device 4 for automatically pressing the bottom cap 101 on the bottle body 102. The material end is connected with the capping device 4.

[0042] Such as Figure 1 to Figure 3 as well as Figure 9 to Figure 14 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com