Preparation process of ceramic roller rod

The invention relates to a technology for a ceramic roller and a preparation process, which is applied in the field of preparation of a ceramic roller, and can solve the problems of small positive extrusion force, deformation of a ceramic roller blank, complex structure, etc., so as to save production costs and facilitate the replacement of parts. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

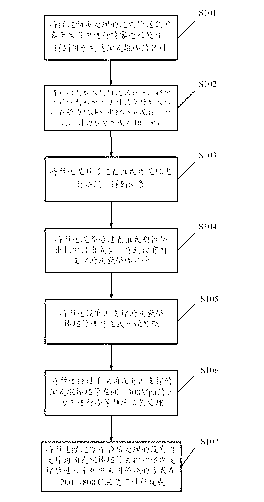

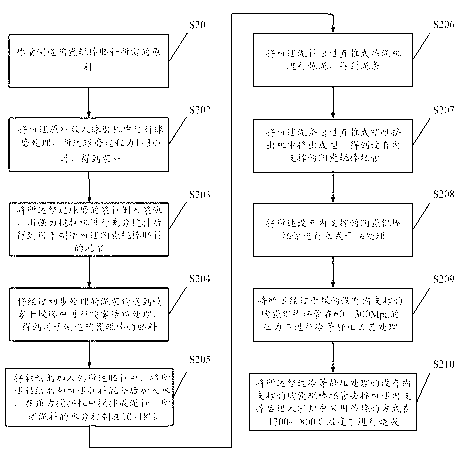

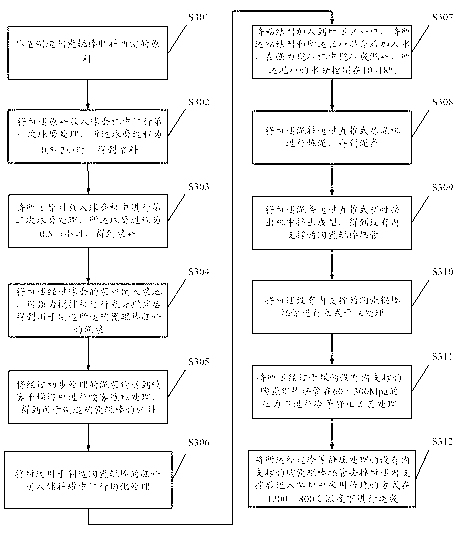

Method used

Image

Examples

Embodiment 1

[0349] Weigh 34% clay, 23% aluminum oxide, and 8% zirconium silicate required for the manufacture of ceramic roller blanks, and put the raw materials into a ball mill for ball milling. The ball milling process is 2 hours to obtain a slurry ; Pour the ball-milled slurry into the slurry tank, and use a strong mixer to fully stir to obtain the slurry used to manufacture the ceramic roller billet; transport the preliminary treated slurry to the spray drying tower for spraying Granules are processed to obtain blanks for manufacturing ceramic rollers; 2% of the binder carboxymethyl cellulose is added to the blanks, and water is added after the binder and the blanks are mixed. Stir into mud in a strong mixer, and the moisture of the mud is controlled at 12%; the mud is smelted through a direct-push mud mixer to obtain a mud bar; the mud bar is passed through a direct-push plastic extrusion Extrude and form in the machine to obtain a ceramic roller billet tube with internal support; c...

Embodiment 2

[0351] Weigh 34% clay, 23% aluminum oxide, and 8% zirconium silicate required for the manufacture of ceramic roller blanks, and put the raw materials into a ball mill for ball milling. The ball milling process is 2 hours to obtain a slurry ; Pour the ball-milled slurry into the slurry tank, and use a strong mixer to fully stir to obtain the slurry used to manufacture the ceramic roller billet; transport the preliminary treated slurry to the spray drying tower for spraying Granules are processed to obtain blanks for the manufacture of ceramic rollers; 2% of the binder polyhydroxycellulose is added to the blanks, and water is added after the binder and the blanks are mixed. Stirring into mud in the mixer, the moisture content of the mud is controlled at 12%; the mud is smelted through a direct-push mud mixer to obtain mud bars; the mud bars are extruded through direct-push plastic Extrude in the machine to obtain a ceramic roller billet tube with an internal support; carry out v...

Embodiment 3

[0353] Weigh 36% of clay required for manufacturing ceramic roller rod stock, 29% of aluminum oxide, and 35% of corundum sand, put the raw material into a ball mill and carry out ball milling, and the ball milling process is 2 hours to obtain the slurry; The ball-milled slurry is poured into the slurry tank, fully stirred with a strong mixer to obtain the slurry used to manufacture the ceramic roller billet; the preliminary treated slurry is transported to a spray drying tower for spray granulation treatment , to obtain the blank for making ceramic rollers; 1% of the binder carboxymethylcellulose is added to the blank, and water is added after the binder and the blank are mixed, and the Stirring into mud, the moisture of the mud is controlled at 12%; the mud is smelted through a direct-push mud mixer to obtain a mud bar; the mud bar is passed through a direct-push plastic extruder Extrude and form in the middle to obtain a ceramic roller billet tube with an inner support; carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com