Technique and equipment for producing reinforcing band

A production process and technology of reinforcing belts, which are applied to belts, other household appliances, household appliances, etc., can solve the problems of thickness and width control of reinforcing belts, affecting the production quality of pipes, large thickness and width, etc., to achieve easy control and satisfactory use. Stable and reliable effect of demand and work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

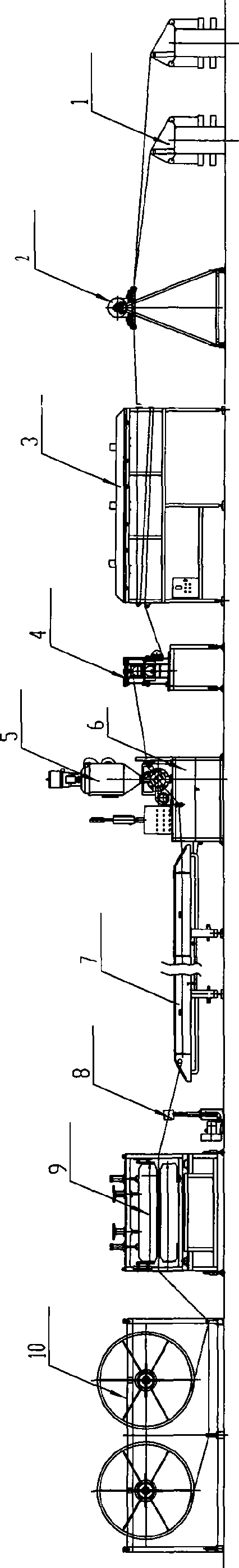

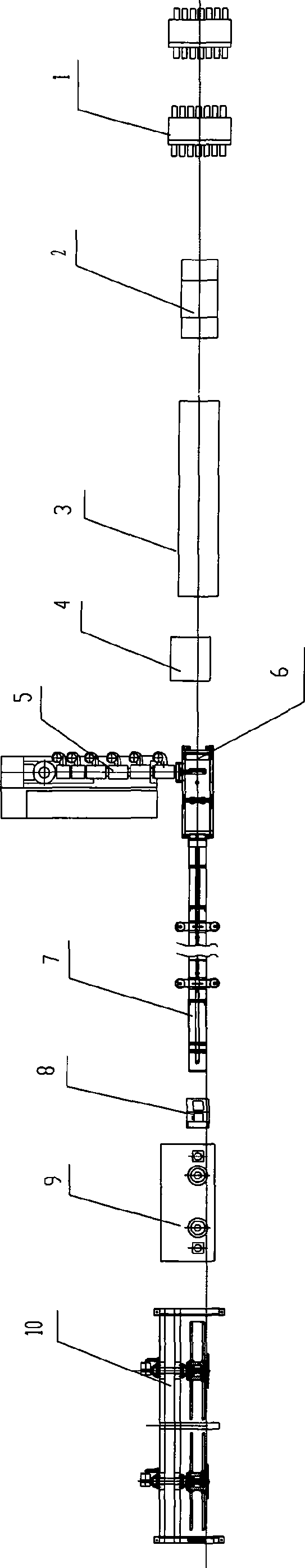

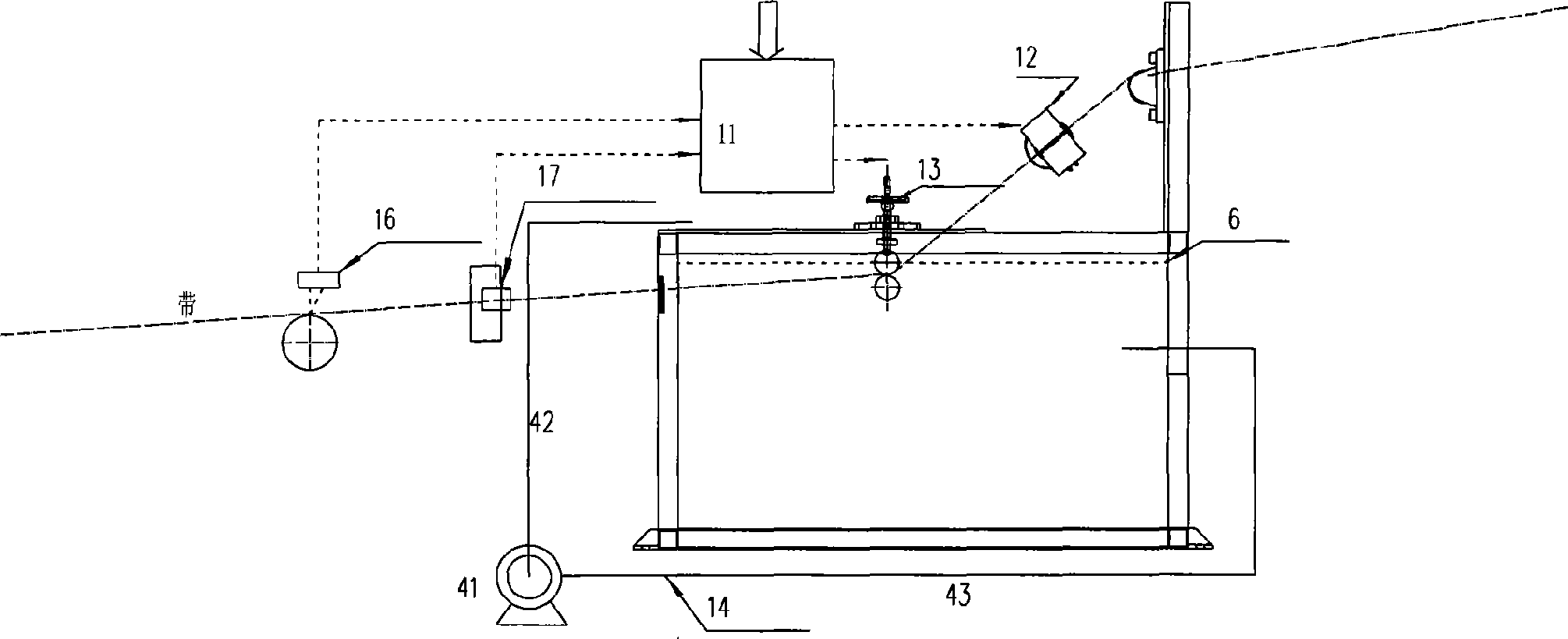

[0029] The production technology of reinforcing band of the present invention comprises the following steps:

[0030] 1) Use the pay-off frame 1 to discharge the fiber spindles or steel wires regularly so that they are arranged into fiber bundles or steel wire bundles;

[0031] 2) Let each bundle of fiber bundles or steel wire bundles pass through the tension controller 2, adjust and control the tension and position of the rows of fiber bundles or steel wire bundles, and work together with the fiber bundle or steel wire bundle tractor 4 to keep the fiber bundles or steel wire bundles tension, and arrange multiple fiber bundles or steel wire bundles equidistantly;

[0032] 3) drying the equidistantly arranged fiber bundles or steel wire bundles with dryer 3;

[0033] 4) The extruder 5 covers a uniform plastic layer between and around a plurality of equidistantly arranged fiber bundles or steel wire bundles through a plastic extrusion die, so that it becomes a thin strip-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com