Device for finely crushing biomass

A fine crushing and biomass technology, applied in grain processing, etc., can solve the problems of high energy consumption, low output, rough output, etc., and achieve the effect of simple equipment structure, high output, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

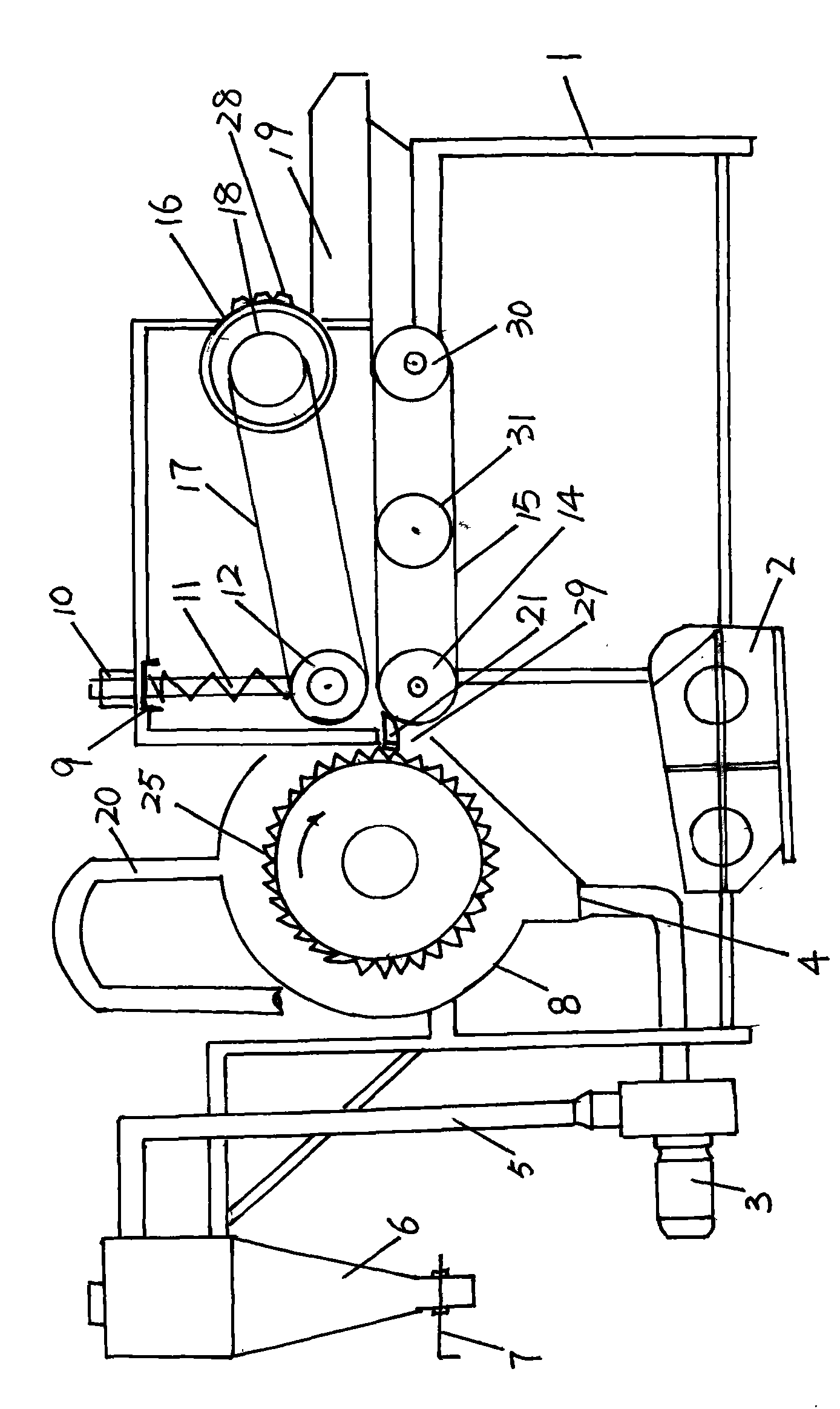

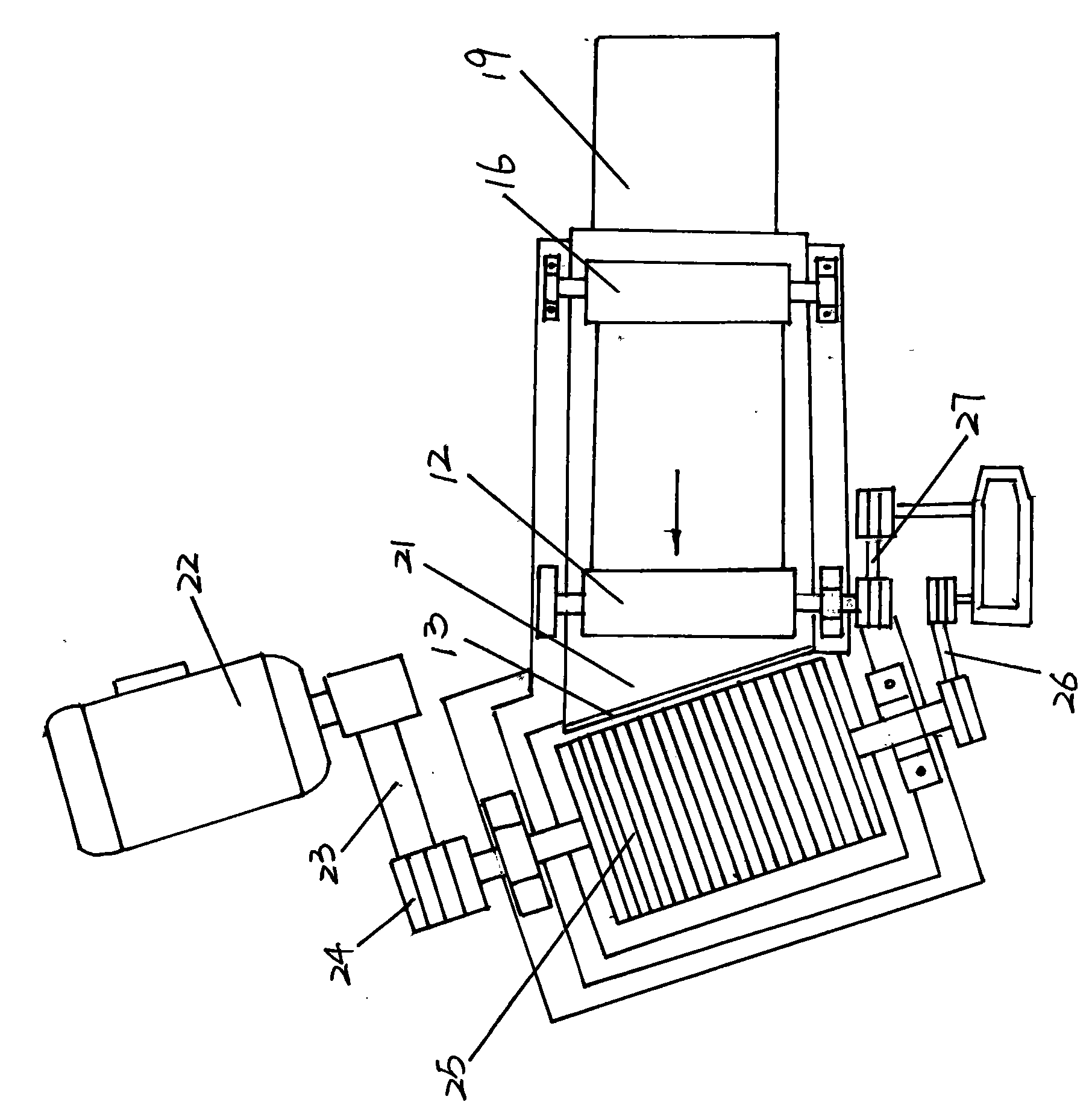

[0014] Biomass fine crushing device, including bracket assembly 1 supporting various parts of the machine, a feeding mechanism and a crushing mechanism, the crushing mechanism includes a strip-shaped hard material fixed knife 13 and the axis is parallel to the edge line of the hard material fixed knife 13 The movable knife combined knife roller 25, establishes 20~30 ° of included angles between the knife-edge line of hard material fixed knife 13 and the feeding direction of feeding mechanism.

[0015] The feeding mechanism includes a delivery roller 16 and a squeeze roller 12 that are arranged successively from the feeding direction. A conveyor belt 15 is arranged below the delivery roller 16 and the squeeze roller 12. The delivery roller 16 is provided with a dial tooth 28, and the delivery roller 16 The vertical distance between the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com