Baseboard cable horizontal arrangement prestress concrete variable cross-section box girder bridge and construction method thereof

A concrete and prestressing technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as uneconomical, main tensile stress cracks in web 2, large prestress loss of curved cables, etc., to simplify structural design and construction, Solve the cracks along the bridge and the effect of small prestress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

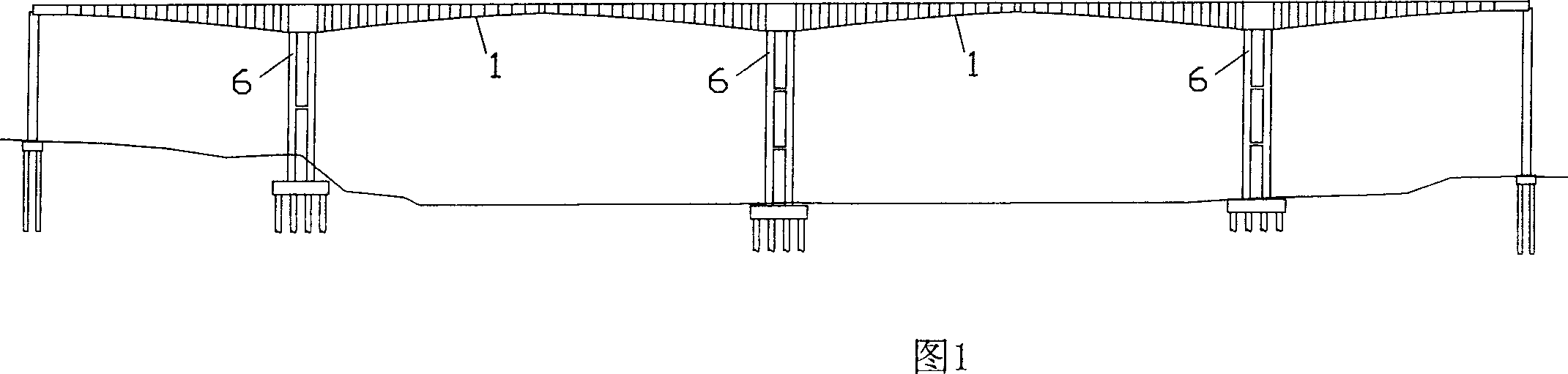

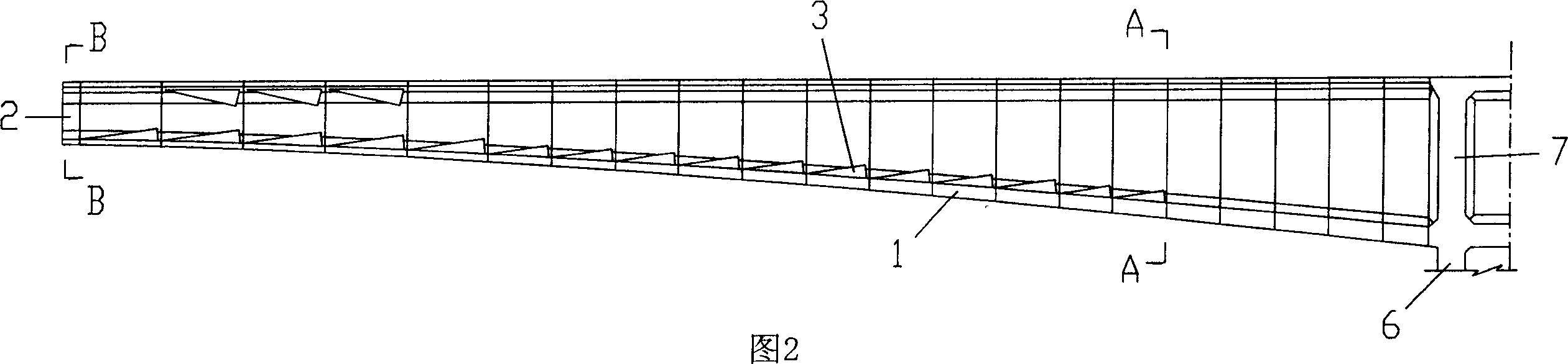

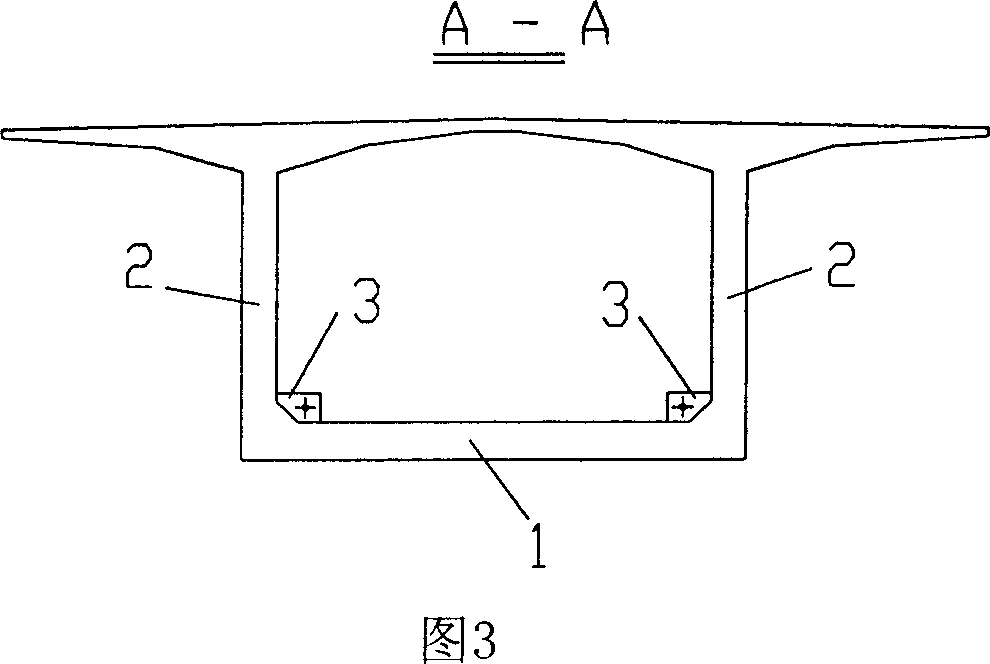

[0036] The long-span prestressed concrete variable-section box girder bridge structure with floor cables arranged horizontally according to the present invention, as shown in Fig. The mid-span mid-slab 1 of the box girder corresponds to the height of the girder, and the horizontal anchor plate 4 is arranged longitudinally, and the horizontal anchor plate 4 is integrated with the box girder bottom plate 1 in the section near the L / 2 section to the 3L / 8 section of the mid-span, and the rest of the positions are integrated with the box girder bottom plate 1. The base plate 1 is separated, and the thickness of the horizontal anchor plate 4 is consistent with that of the mid-span base plate 1, generally 25-40 cm. As shown in Figures 11 to 13, the bottom cable 5 is arranged in the horizontal anchor plate 4, and the sawtooth block 3 is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com