Box type baseboard prestress concrete variable cross-section box girder bridge and construction method thereof

A concrete and variable cross-section technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as increased self-weight, web 2 main tensile stress cracks, mid-span floor 1 shear cracks, etc., to achieve simplified structural design and The effect of construction, shrinkage, creep, deflection, and shear resistance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

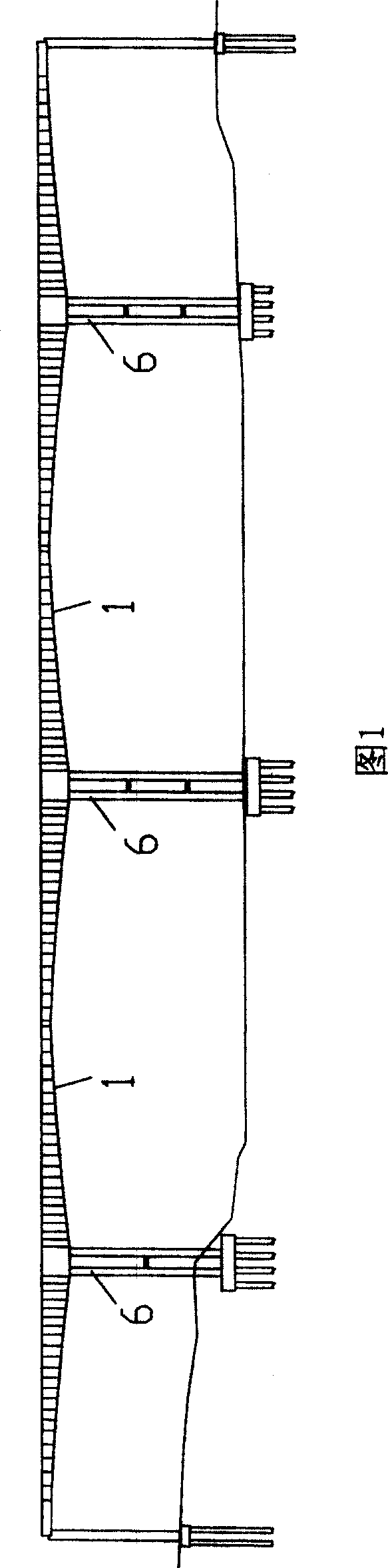

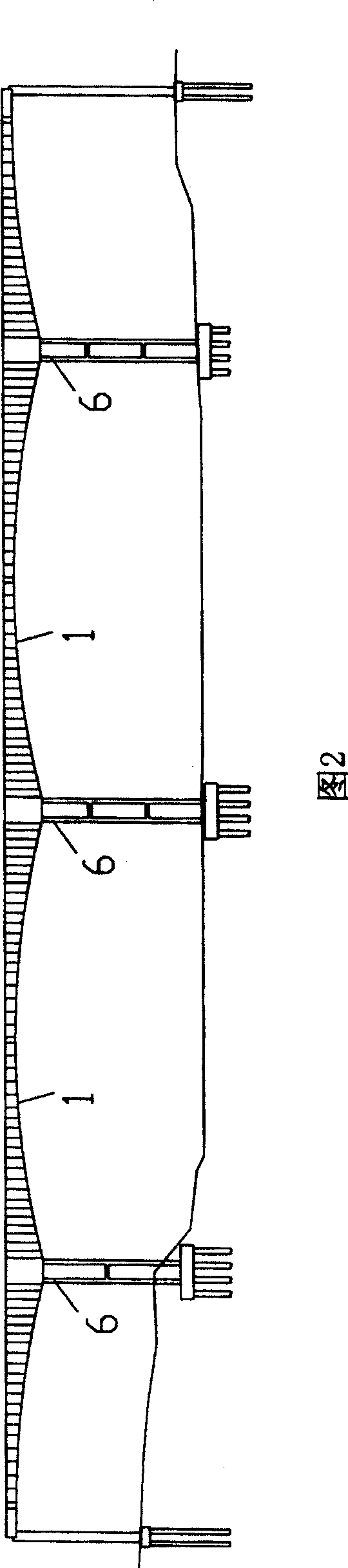

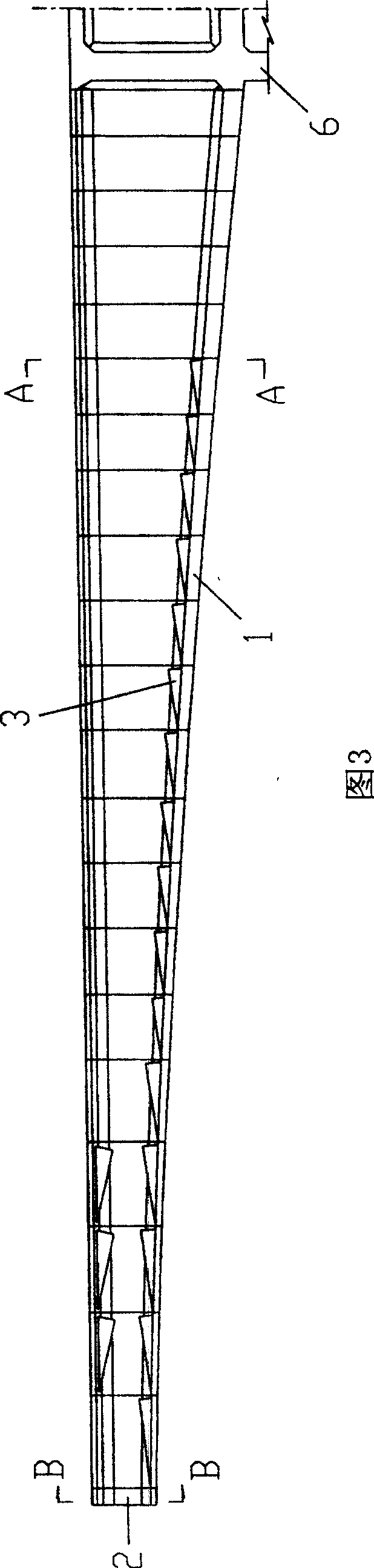

[0047] See Figure 6 to Figure 12And as shown in Figures 17 to 20, the long-span prestressed concrete variable-section box girder bridge with box-type bottom plate of the present invention includes the bottom plate, web plate, and bottom plate cables in the pier and box girder. The bottom plate of the box girder adopts a box-shaped bottom plate, which is composed of a bottom plate 11 of the box-shaped bottom plate, a top plate 12 of the box-shaped bottom plate parallel to it, and webs 2 on both sides. The height of the entire box-shaped bottom plate is 1 / 4 to 1 / 5 of the total girder height H of the 6 fulcrums of the bridge pier. The section from the L / 4 section to the fulcrum of the cantilever root adopts a bottom plate box with equal cross-section. The top plate 12, bottom plate 11 and The webs 2 of the box girder are all of equal thickness, and the thickness is 40-60 cm. The net rise-span ratio of the lower edge of the bottom plate 11 of the floor box is 1 / 7 to 1 / 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com