Built-in oblique leg rigid-frame prestress concrete variable cross-section box girder bridge and construction method thereof

A variable-section, pre-stressed technology, used in the erection/assembly of bridges, bridges, bridge materials, etc., can solve the problems of increasing self-weight, main tensile stress cracks in web 2, large downward radial force, etc., to achieve simplification Effects of structural design and construction, small shrinkage creep deflection, and enhanced shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

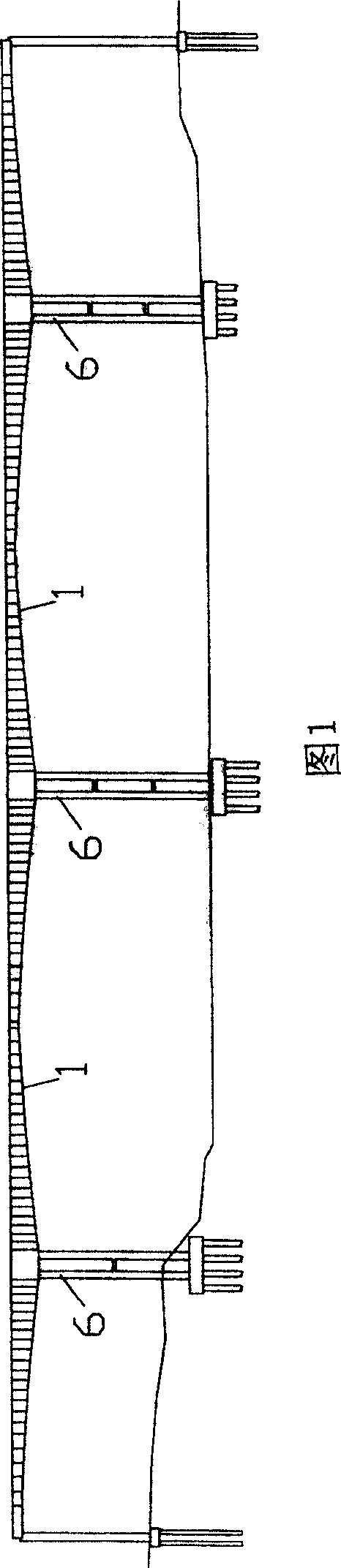

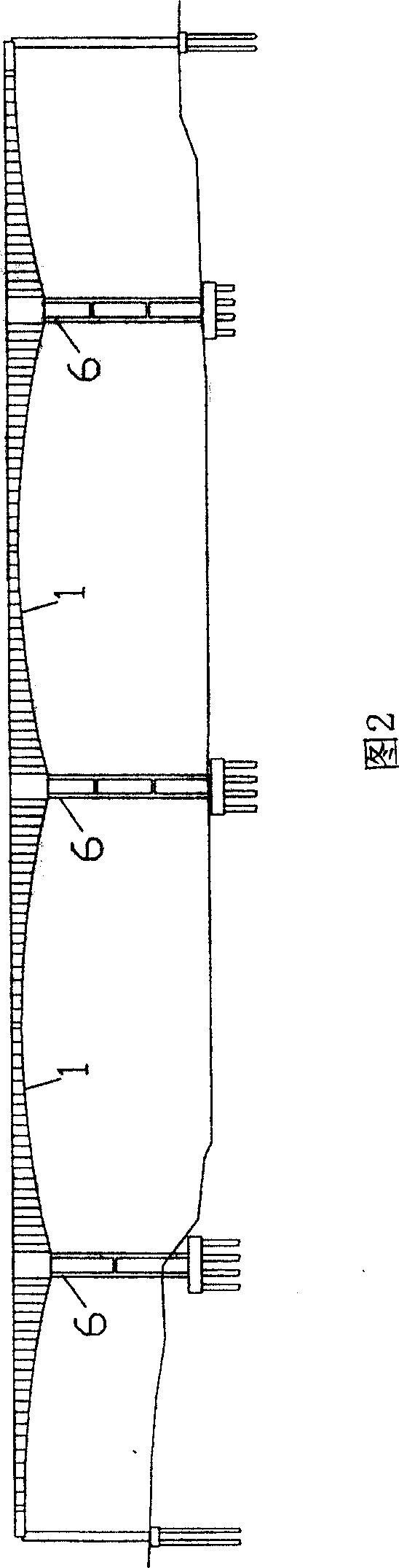

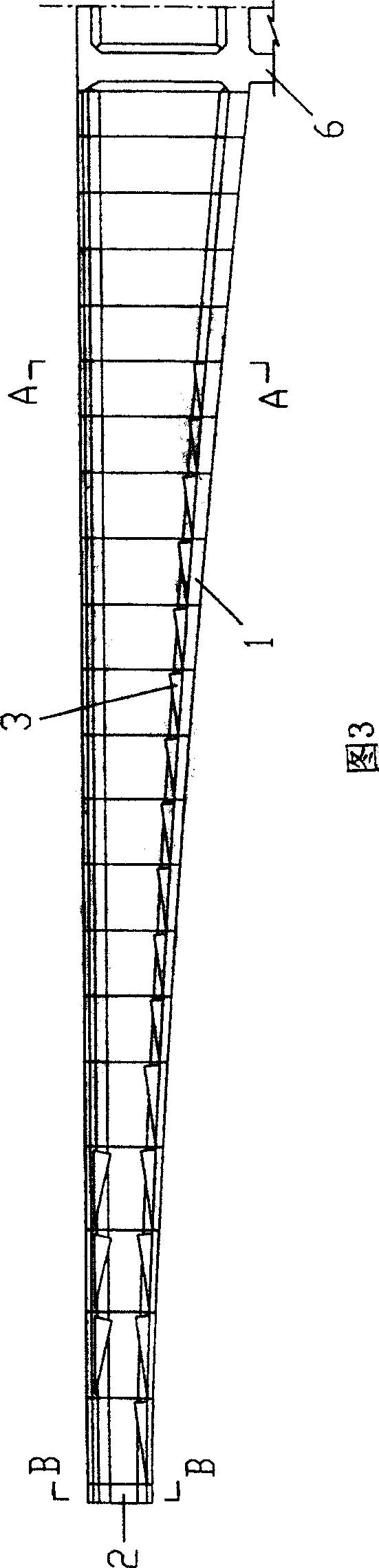

[0047] See Figures 6 through 12 and Figures 17 through Figure 20 As shown, the present invention has a built-in oblique-leg rigid frame prestressed concrete variable-section box girder bridge, including pier 6 and bottom plate 1 and web 2 forming the box girder. Leg rigid frame structure, oblique leg rigid frame structure is composed of built-in longitudinal beams 41 and built-in oblique legs 42. The built-in oblique legs 42 and the bottom plate 1 of the box girder are arranged in parallel, the radial distance between the built-in inclined legs 42 and the bottom plate 1 is 1 / 4 to 1 / 5 of the total girder height H of the fulcrum, and the built-in inclined legs 42, the bottom plate 1 of the box girder and the web 2 All adopt the same section, and the thickness is 40-60cm. The lower edge of the box girder floor 1 adopts a suspension line, which has the effect of an arch bridge landscape, and the net rise-span ratio is 1 / 7 to 1 / 9. The built-in longitudinal beam 41 is set at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com