Slant leg rigid frame built-in prestressed concrete variable cross-section box girder bridge and construction method thereof

A concrete and prestressed technology, applied in the field of prestressed concrete variable section box girder bridges with built-in inclined leg rigid frame, can solve the problem of poor web 02 stability and box girder torsion resistance, aggravating concrete shrinkage and creep effect, Provide problems such as eliminating or reducing control methods to achieve the effect of reducing the hollow rate of horizontal sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

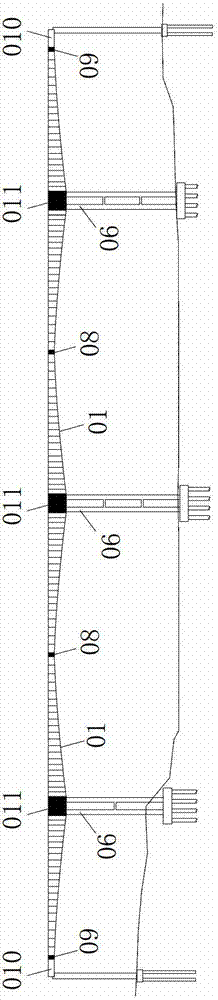

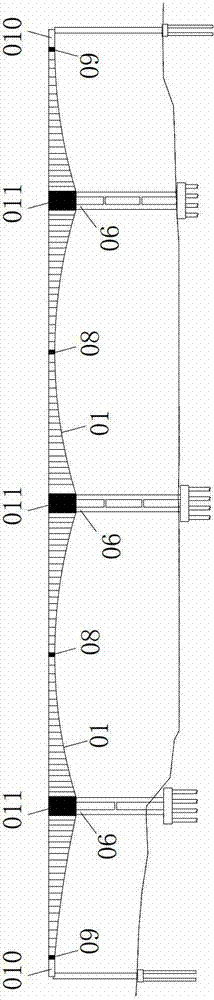

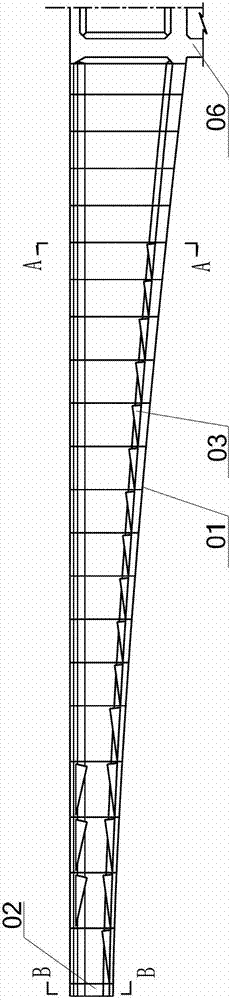

[0082] The first object of the present invention is to provide an upward radial force generated by the mid-span positive moment floor cable, which can eliminate or reduce the influence of the downward deflection of the main girder caused by the second-stage dead load, and the overall structure has high rigidity, small deflection, and Strong shear capacity, provide reasonable cables and anchoring positions for positive moment cables, reduce the hollowing rate of the bottom plate section and the flat bending amplitude of the bottom plate cables, good web stability and box girder torsion resistance, reasonable box girder structure stress, A prestressed concrete variable-section box girder bridge with built-in oblique-leg rigid frame and convenient construction. The second object of the present invention is also to provide a construction method for a prestressed concrete variable-section box girder bridge with built-in oblique-leg rigid frame.

[0083] The following will clearly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com