An adss optical cable force unloading device for an iron tower

A technology for optical cables and iron towers, which is applied in the field of ADSS optical cable force unloading devices for iron towers, can solve the problems of unsuitable middle corner towers, excessive sag of ADSS optical cables, etc., so as to prevent excessive sag, reduce the impact, and reduce the level The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

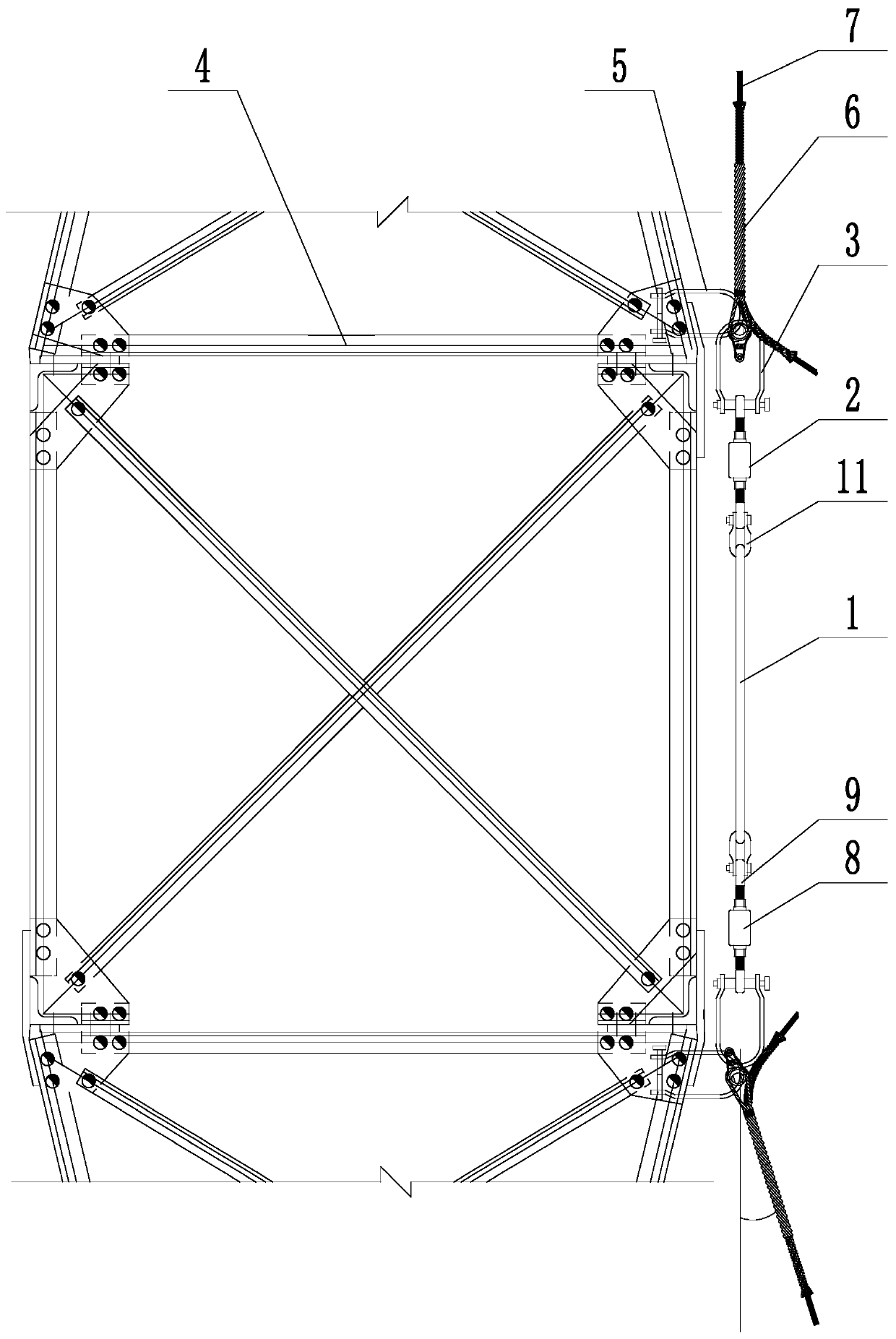

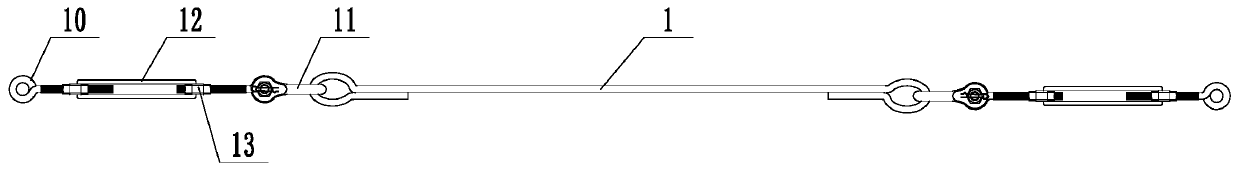

[0024] Embodiment 1: a kind of iron tower uses ADSS optical cable unloading device (referring to attached figure 1 , attached figure 2 ), including connecting rod 1, two adjusting rods 2 connected to the two ends of the connecting rod with adjustable length, and a pulling ring 3 connected to the adjusting rod. The connecting rod is a single rod, and the two pulling rings are connected for installation on the iron tower The supporting ring 5 on the 4, the pulling ring and the supporting ring are all U-shaped structures. The movable hook of the pulling ring is hung on the supporting ring, and the pulling ring is connected with a pre-twisted wire 6 for tension, and the pre-twisted wire is connected with the ADSS optical cable 7, and the two pre-twisted wires are tightened for the connecting rod. The pull ring can be adjusted and moved along the extension line direction of the connecting rod. The adjusting rod includes a rod body 8, two connecting screw rods 9 that are threaded...

Embodiment 2

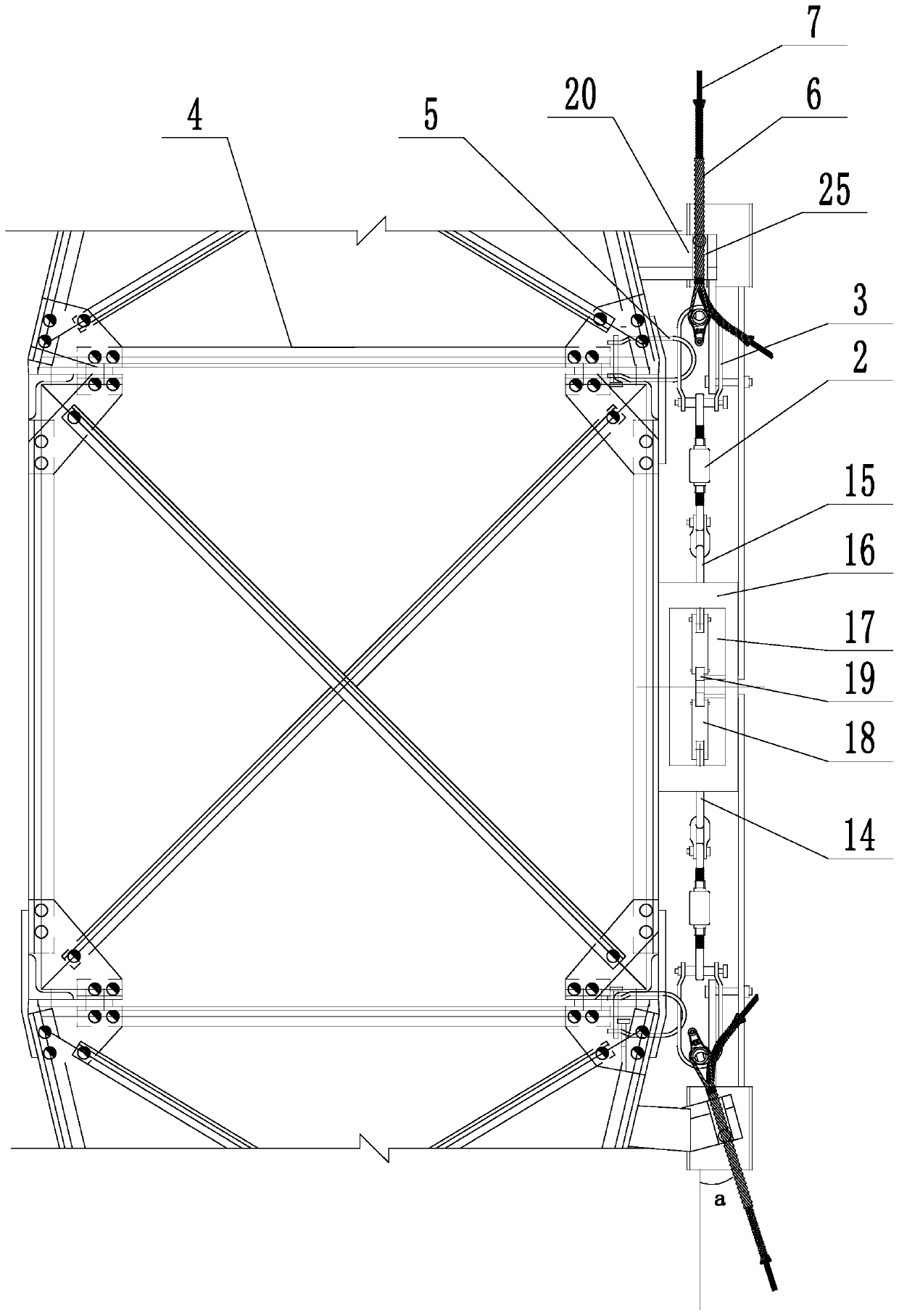

[0026] Embodiment 2: a kind of iron tower uses ADSS optical cable unloading device (referring to attached image 3 to attach Figure 5 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment the connecting rod includes a left tie rod 14, a right tie rod 15, and a connecting support 16 between the left and right tie rods, the support is installed on the iron tower, and the support There is a slot 17 on the top, and the left and right pull rods move through the slots. The ends of the left and right pull rods are hinged to adjust the connecting rod 18, and the push block 19 is hinged between the two adjusting rods; A support block 20 is installed, and the corresponding position of the ADSS optical cable on the support block can be lifted and connected to the push column 21. The ADSS optical cable is attached to the upper end of the push column, and the lower end of the push column is abutted against the abutment plate 22. The rod is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com