Method for controlling conductor length between through hole and welding disk of printed circuit board

A printed circuit board and wire length technology, applied in the electronic field, can solve the problems of PCB board error inspection and modification difficulties, more time and cost, and quality cannot be guaranteed, so as to improve product quality and work efficiency, avoid inspection and Effects of modification and shortening of design time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

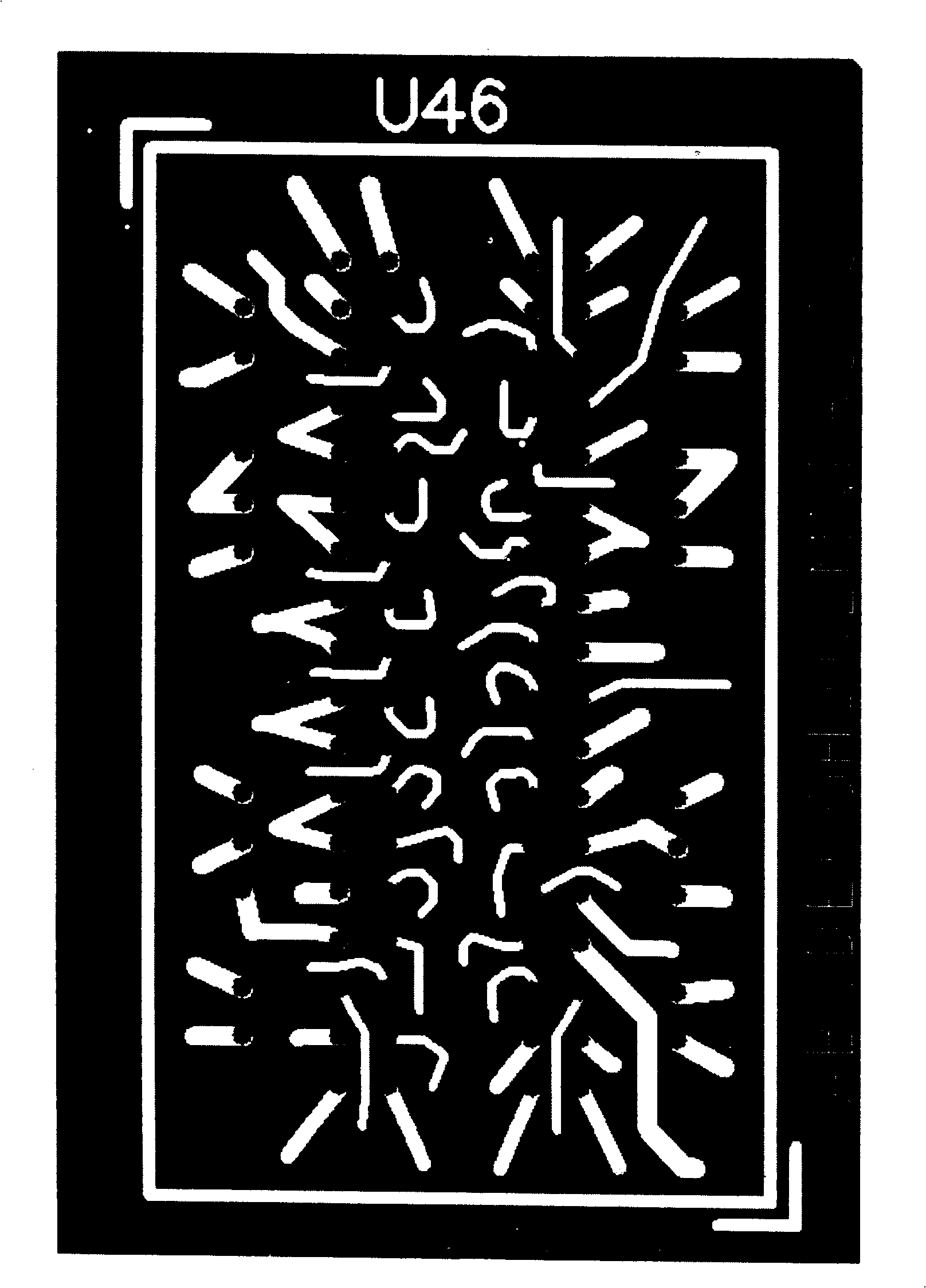

Image

Examples

Embodiment Construction

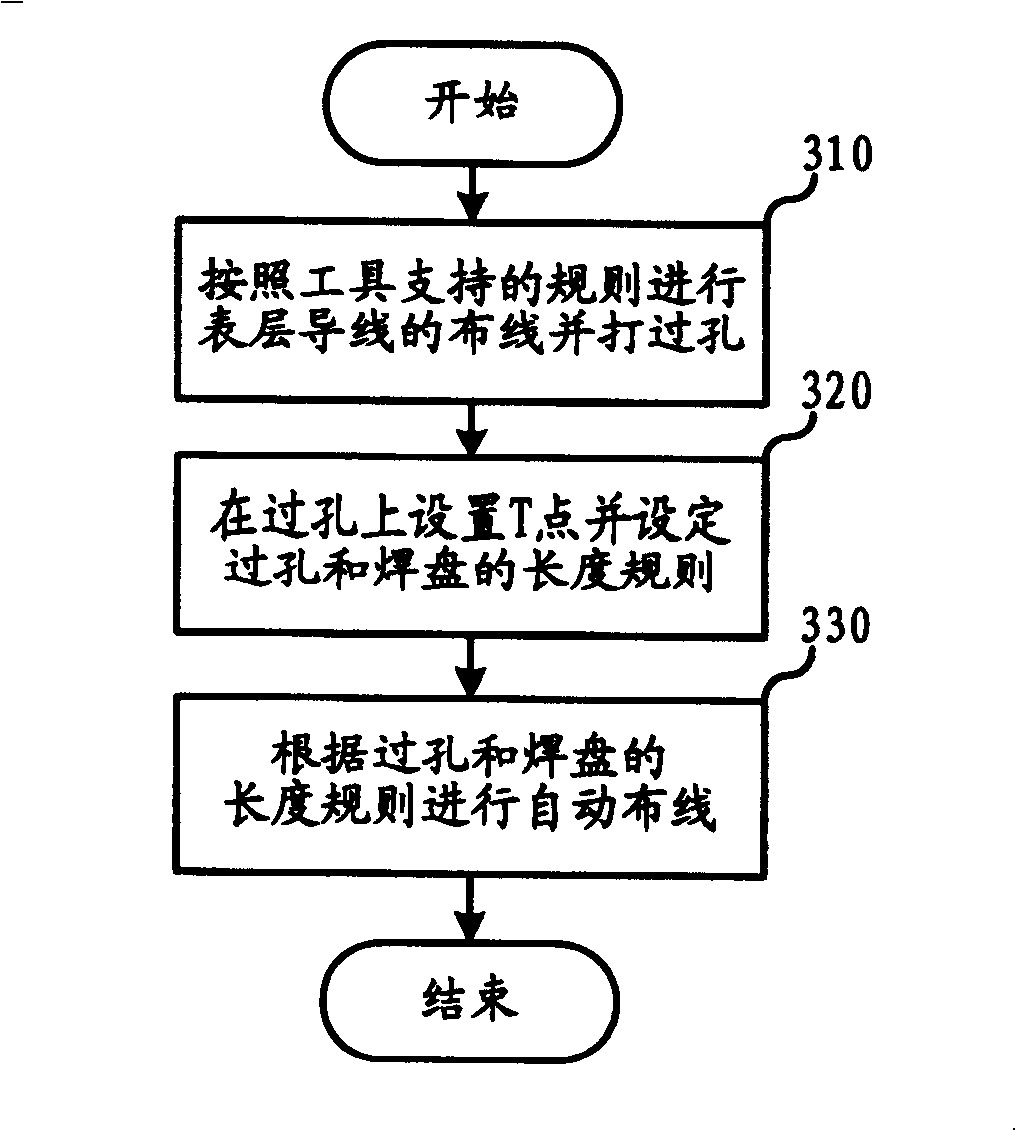

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

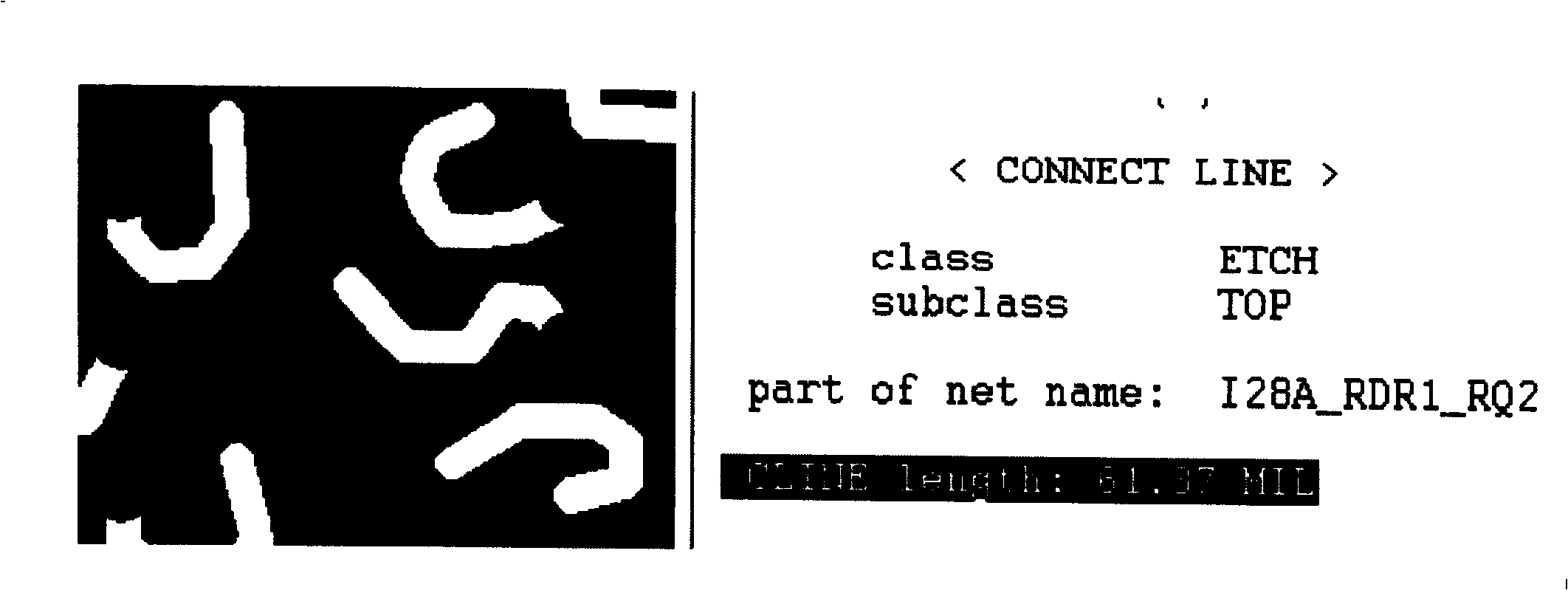

[0044]Considering that the EDA tool can automatically measure the distance from the T point to the pad, the solution of the present invention automatically adds the T point on the via hole, and sets constraint rules for each T point, and then the automatic routing function of the EDA tool can be used for routing , and finally you can check whether the wiring meets the requirements through the rule list. By using the solution of the invention, manual wiring is changed to automatic wiring, which will greatly help the improvement of PCB design efficiency and quality, facilitate inspection, shorten design time and reduce design cost.

[0045] According to the preferred embodiment of the present invention, the process of PCB via hole and wire length control between pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com