BIM-based No.0 block longitudinal prestressed pipeline positioning construction method

A technology of prestressed pipelines and construction methods, applied in special data processing applications, erecting/assembling bridges, bridges, etc., to achieve high rigidity, reduced durability and structural safety, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

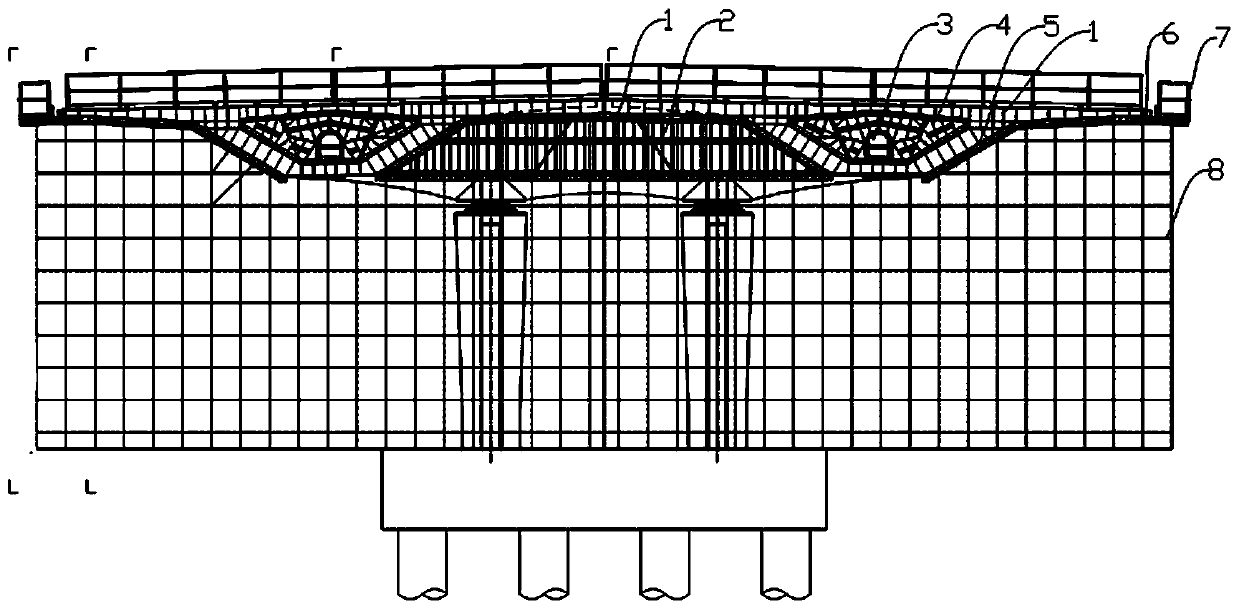

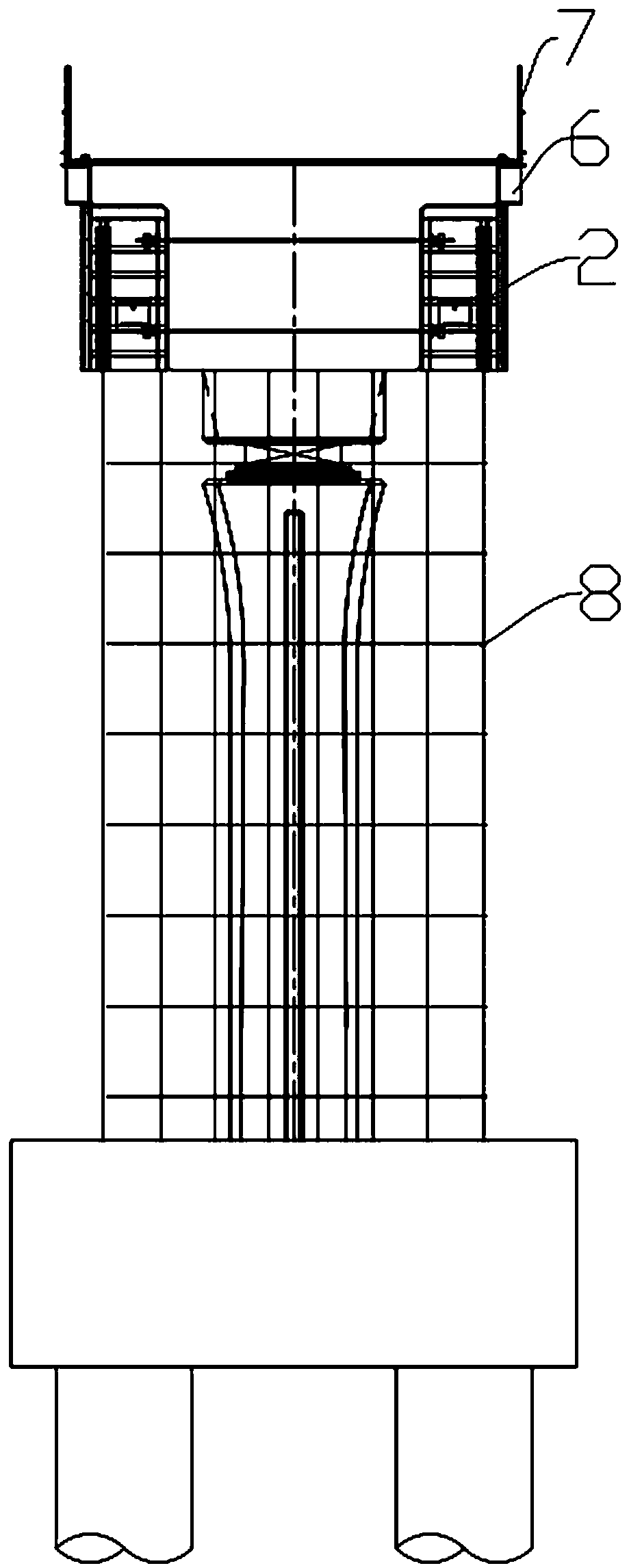

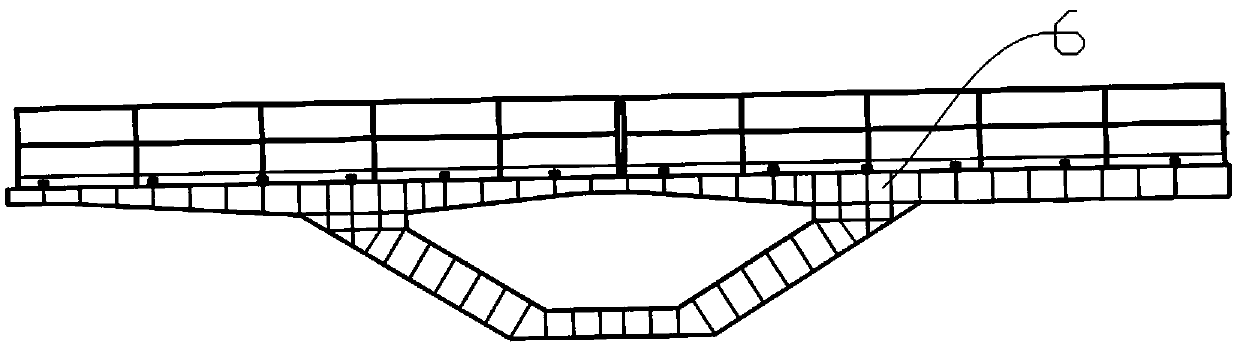

[0035] Example 1: A BIM-based construction method for positioning longitudinal prestressed pipelines in Block 0, see Figure 1~5 , including the following steps:

[0036] 1) Modeling with BIM: first draw the BIM graph of the position of the No. 0 steel bar and the prestressed pipe hole, find out the collision position, optimize the position of the steel bar, and optimize and adjust the position of the steel bar in advance to ensure the accurate positioning of the prestressed pipe; The total station performs positioning and setting out on the bottom formwork, the direction of the prestressed pipeline, and the positioning steel bars, and assists the measuring tape to reduce the difficulty of prestressed pipeline installation; the accuracy of the position of the No. 0 block end formwork and the prestressed pipeline hole Design and simulate the trial assembly; extract the measurement data and trial assembly data of the No. 0 block end formwork and the position of the prestressed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com