Construction method for installing support rapidly by using rear chambering self-locking anchor rod

A technology of self-locking bolts and construction methods, which is applied in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of inconvenient fixing, long construction time, and difficult quality assurance, and achieve the convenience of mechanized construction and installation speed. Fast, quick to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

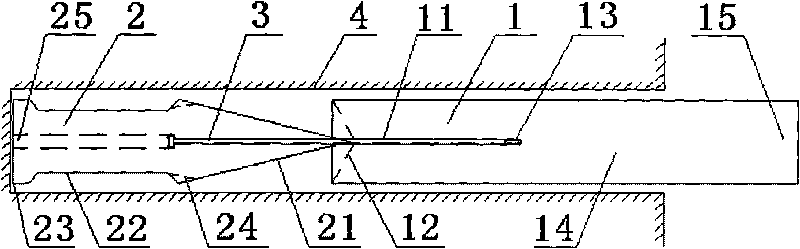

[0024] see Figure 1-Figure 5 , 1. a construction method for fast installation and support of rear reaming self-locking bolt, comprising the following steps:

[0025] A. Use high-pressure air to remove the residue in the anchor hole 4;

[0026] B. Insert the wedge 2 of the anchor rod and the anchor end 1 in the rod body to the bottom of the anchor hole 4; and install the reaming anchor rod installer on the exposed end 15 of the rod in the anchor hole 4;

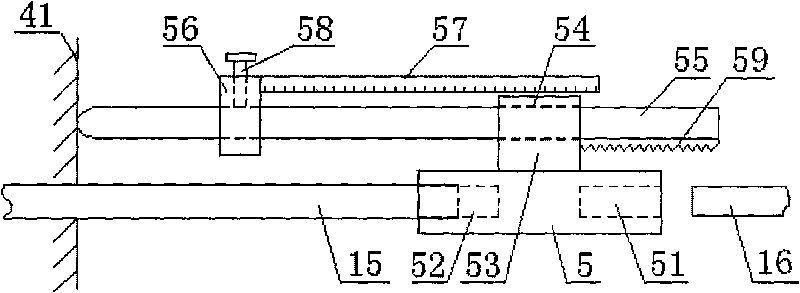

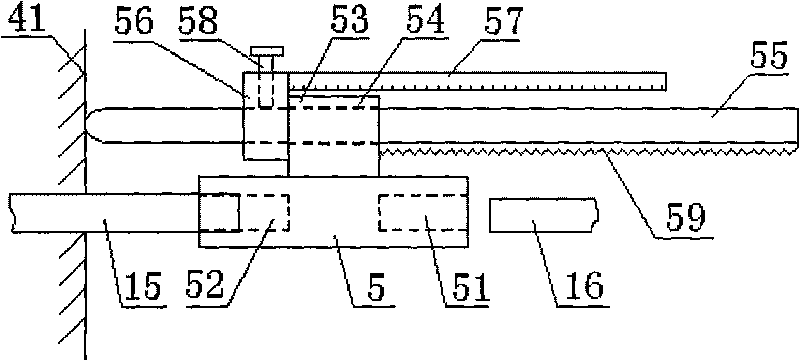

[0027] C. According to the axial stroke of the anchor rod after the anchor end 1 is stretched out in the rod body, the sliding distance of the slide rod seat 53 of the rear reaming anchor rod installer on the slide rod 55 is calibrated;

[0028] D. Install the drill rod 16 on the air pick, insert the drill rod 16 into the drill rod blind hole 51 of the straight rod 5 on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com