Pretensioned beam whole opening prefabricated construction method

A construction method and construction preparation technology, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of large span, difficult construction, and large tonnage, and achieve the effect of ensuring force, improving efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

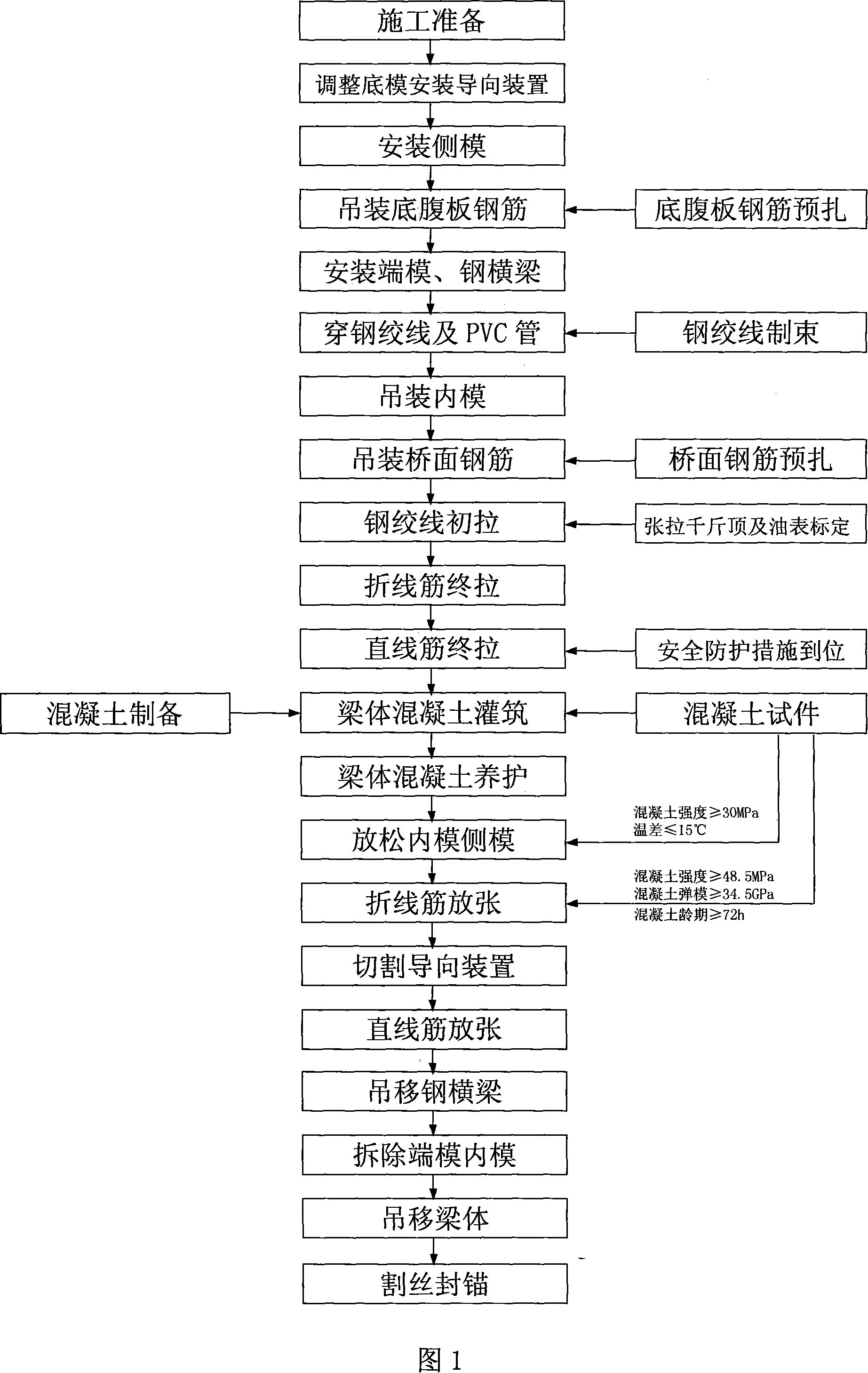

[0075] The technical process of the pre-tensioned beam whole hole prefabrication construction method in this embodiment is shown in Figure 1, and its main processes include:

[0076] (1), construction preparation,

[0077] (2), adjust the bottom mold, install the guide device,

[0078] (3), install the side formwork,

[0079] (4), hoisting bottom web reinforcement,

[0080] (5), install end formwork, steel beam,

[0081] (6), wear steel strands and PVC pipes

[0082] (7), lifting the inner mold,

[0083] (8), hoisting bridge deck reinforcement,

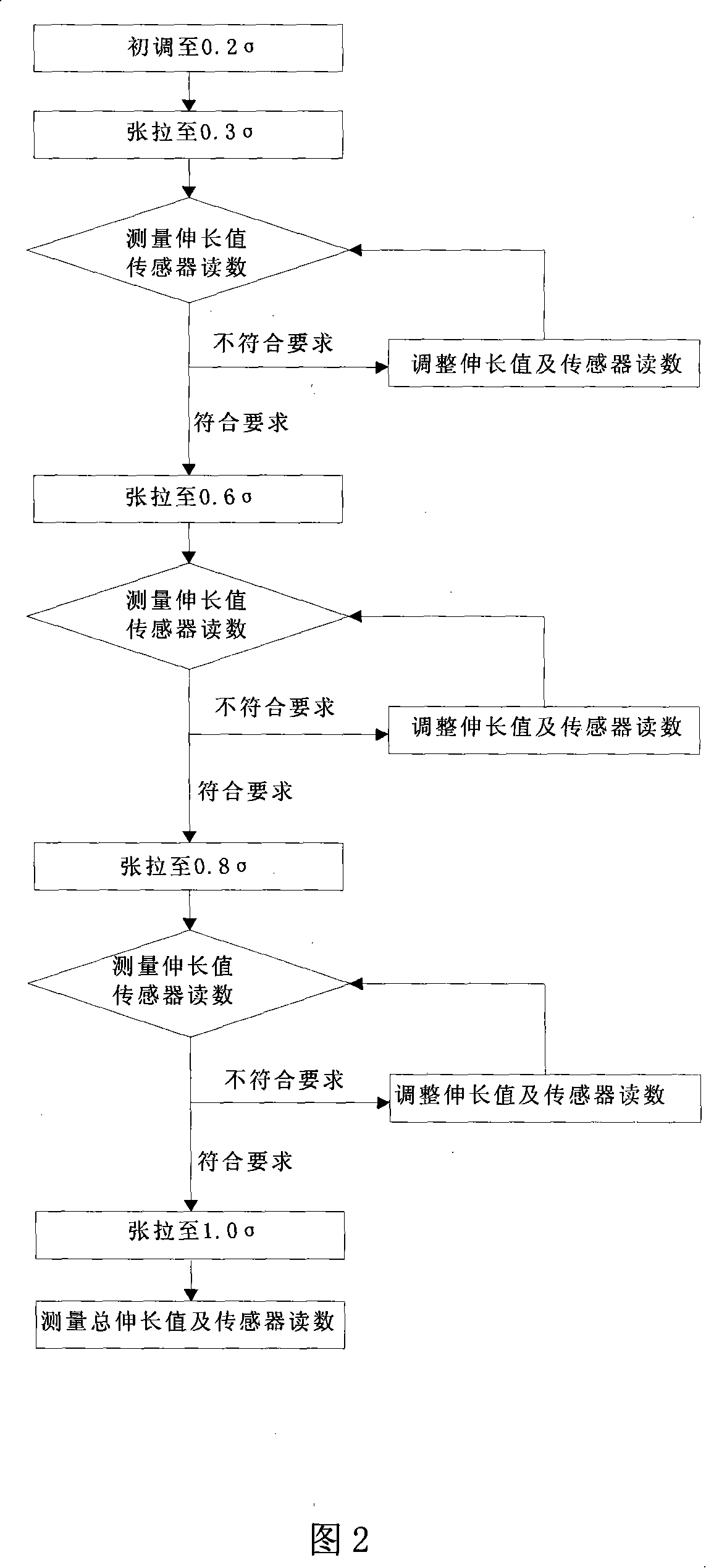

[0084] (9), the steel strand is initially pulled,

[0085] (10), the final pull of the broken line tendon,

[0086] (11) Straight tendon final pull,

[0087] (12), beam concrete filling,

[0088] (13), beam concrete maintenance,

[0089] (14), relax the inner mold side mold,

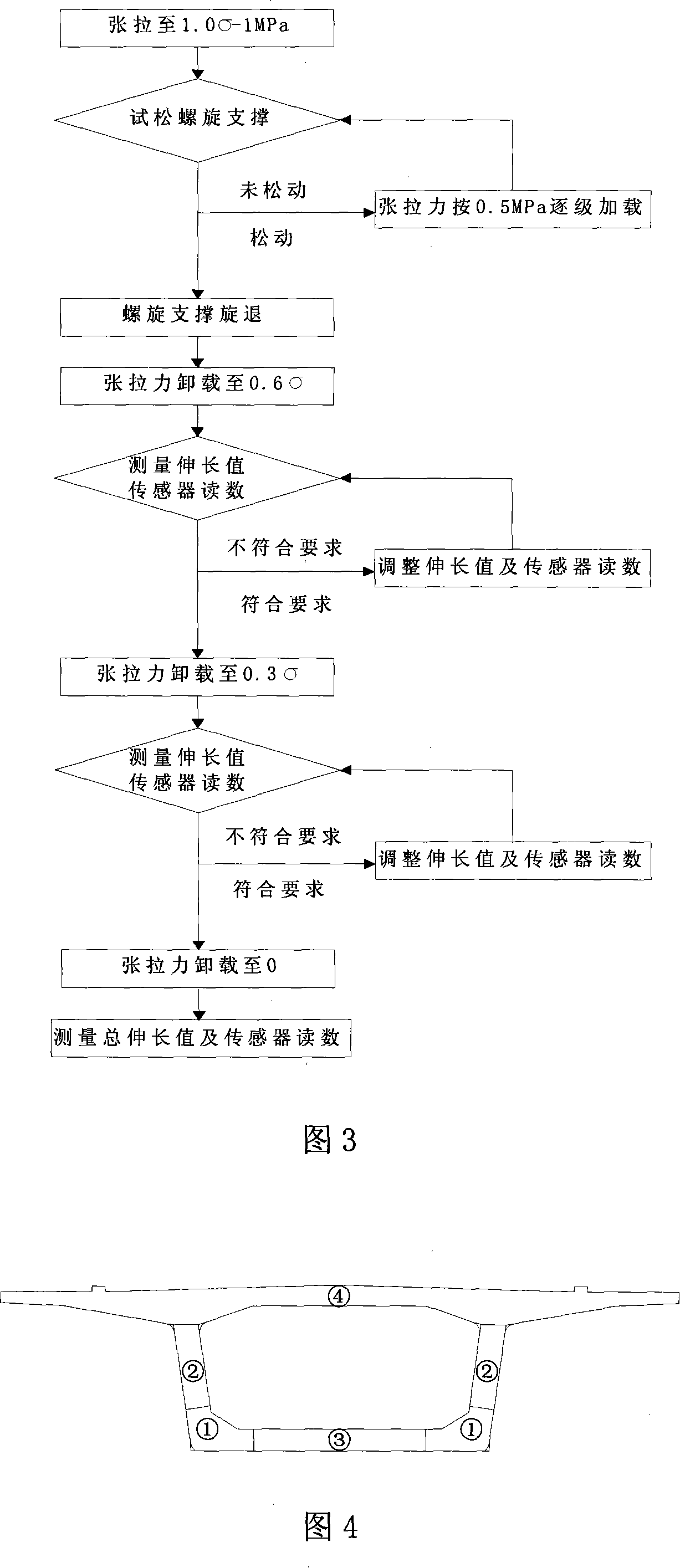

[0090] (15), the broken line ribs are stretched,

[0091] (16), cutting guide device,

[0092] (17), stretching the straight tendons,

[0093] (18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com