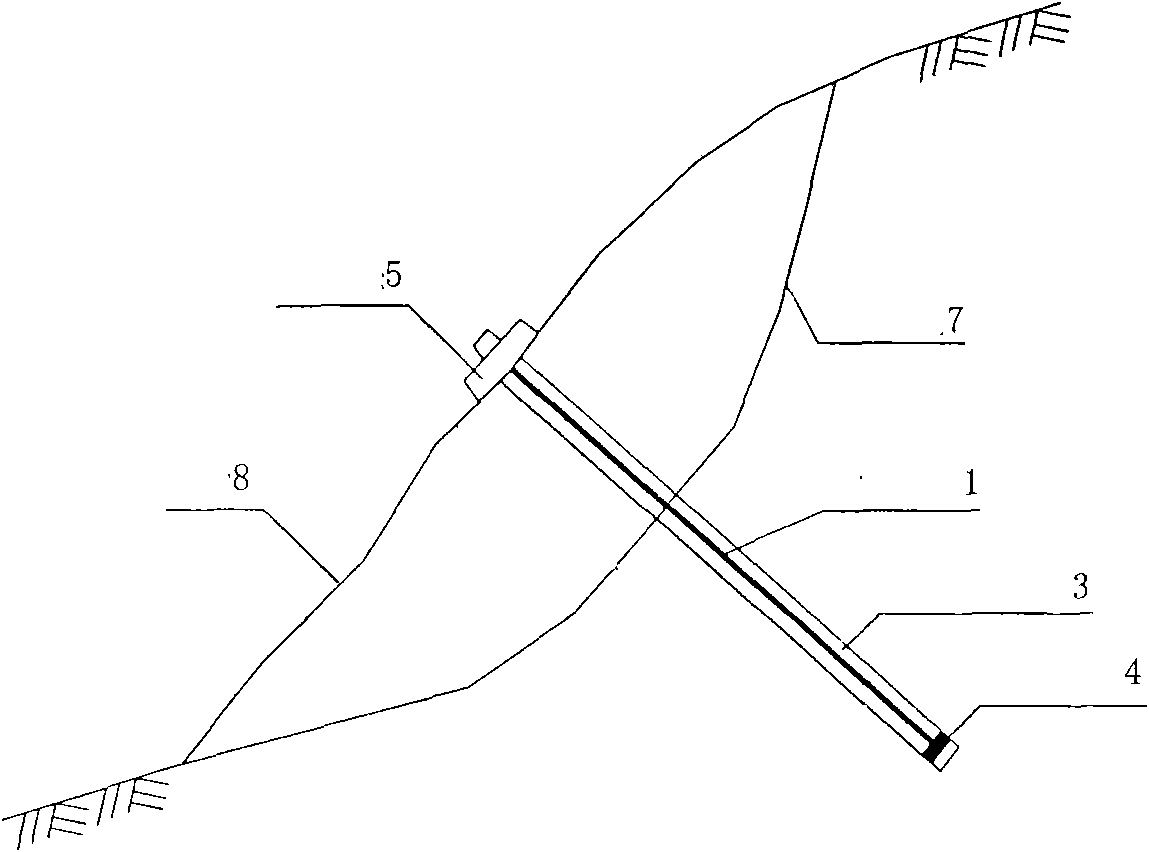

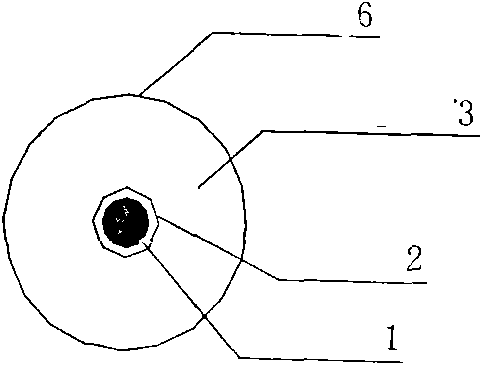

Pressure-type carbon fiber prestressing force anchor cable land-sliding control structure

A prestressed anchor cable, carbon fiber technology, applied in the direction of foundation structure engineering, sheet pile wall, excavation, etc., can solve the problems of high installation strength, poor durability, low specific strength, etc., and achieve easy transportation, reduced transportation, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Example: For a specific landslide prevention and control project, through investigation and design work, it is determined that the pressure-type carbon fiber prestressed anchor cable structure is used for prevention and control. According to the design document, first use measuring equipment to measure and locate the prestressed anchor cable hole position; Drill holes according to the diameter and depth of a single anchor cable. At the same time, the pressure-type carbon fiber anchor cable is processed and made indoors. Since the carbon fiber anchor cable is unbonded, it is necessary to wrap the PVC casing outside the carbon fiber bundle. Set bearing steel plate at the end; clear holes and install pre-stressed anchor cable; inject M30 cement mortar; cast-in-place pre-stressed anchor cable anchor pier; when the strength of concrete and mortar reaches 70% of the design strength, perform pre-stress tensioning and lock ; Finally, seal the anchor head of the prestressed anchor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com