Tensional anchoring system for secondary clamping of prestressed sheets

An anchoring system and prestressing technology, which is applied in the processing of building materials, building maintenance, construction, etc., can solve the problems of prestress loss, anchorage anchorage ability cannot be fully exerted, cannot be dismantled and reused, etc. The effect of stress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

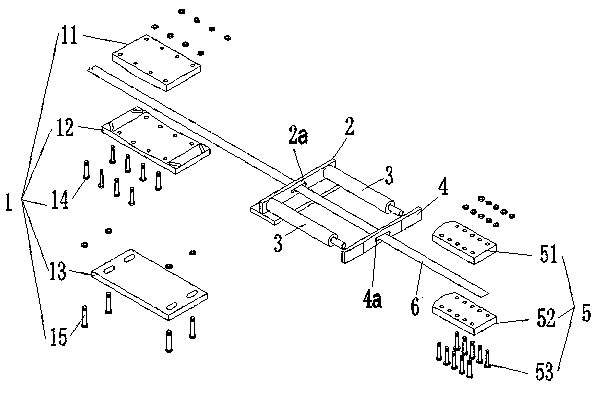

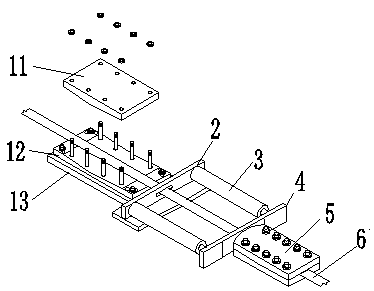

[0045] Such as figure 1 , figure 2 The prestressed sheet secondary clamping and tensioning anchorage system shown is composed of anchoring anchor combination 1, tension bearing block 2, horizontal jack 3, tension bearing block 4 and tension anchor combination 5, etc. . Anchor anchor combination 1, tension bearing block 2, horizontal jack 3, tension bearing block 4 and tension anchor combination 5 are placed in sequence from front to back. One end of the horizontal jack 3 is placed on the tension bearing block 2, and the other end faces the tension bearing block 4.

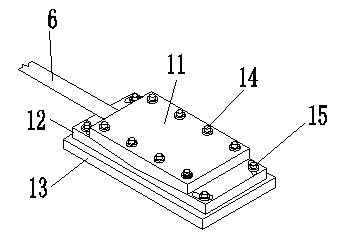

[0046] Anchor anchor combination 1 is composed of upper anchor splint 11 , lower anchor splint 12 , base 13 , permanent clamping bolt and nut 14 and force transmission bolt 15 . The upper anchoring splint 11, the lower anchoring splint 12 and the base 13 are arranged sequentially from top to bottom. The upper anchoring splint 11 and the lower anchoring splint 12 fit each other through curved surfaces, and can b...

Embodiment 2

[0050] The prestressed sheet secondary clamping and tensioning anchorage system is also composed of anchorage and anchorage combination 1, tension bearing block 2, horizontal jack 3, tension bearing block 4 and tension anchorage combination 5, etc. The tension bearing block 2, the horizontal jack 3, the tension bearing block 4 and the tension anchor combination 5 are exactly the same as the embodiment 1, and the difference with the embodiment 1 is: as Figure 4 As shown, the anchoring and anchoring combination 1 is composed of an upper anchoring splint 11, a lower anchoring splint 12 and a base 13. The upper anchoring splint 11, the lower anchoring splint 12 and the base 13 are arranged sequentially from top to bottom. The upper anchoring splint 11 and the lower anchoring splint 12 fit each other through curved surfaces, and can be fastened together by permanently clamping bolts and nuts 14. The lower anchor splint 12 and the base 13 are fastened together through the force tran...

Embodiment 3

[0052] The prestressed sheet secondary clamping and tensioning anchorage system is also composed of anchorage and anchorage combination 1, tension bearing block 2, horizontal jack 3, tension bearing block 4 and tension anchorage combination 5, etc. The tension bearing block 2, the horizontal jack 3, the tension bearing block 4 and the tension anchor combination 5 are exactly the same as the embodiment 1, and the difference with the embodiment 1 is: as Figure 5 As shown, the anchorage combination 1 is composed of an upper anchoring splint 11, a lower anchoring splint 12, a permanent clamping bolt and nut 14, and a force transmission bolt 15. The upper anchoring splint 11 and the lower anchoring splint 12 fit each other through curved surfaces, and can The clamping bolts and nuts 14 are fastened together, the lower anchor splint 12 is provided with a force transmission bolt 15 extending up and down the axis, and the four force transmission bolts 15 are distributed in a rectangle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com