Prestress Bailey beam for reinforcement and construction method thereof

一种预应力、贝雷梁的技术,应用在桥梁加固、桥梁、桥梁材料等方向,能够解决增加结构截面积和自重、混凝土结构开裂、施工过程复杂等问题,达到自重增加小、保护预应力束、施工工期短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

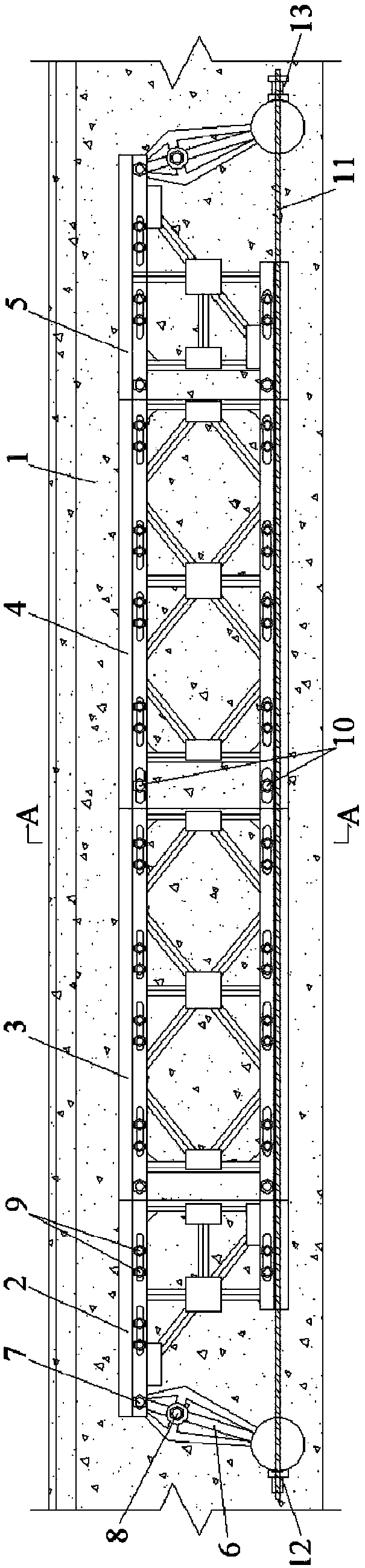

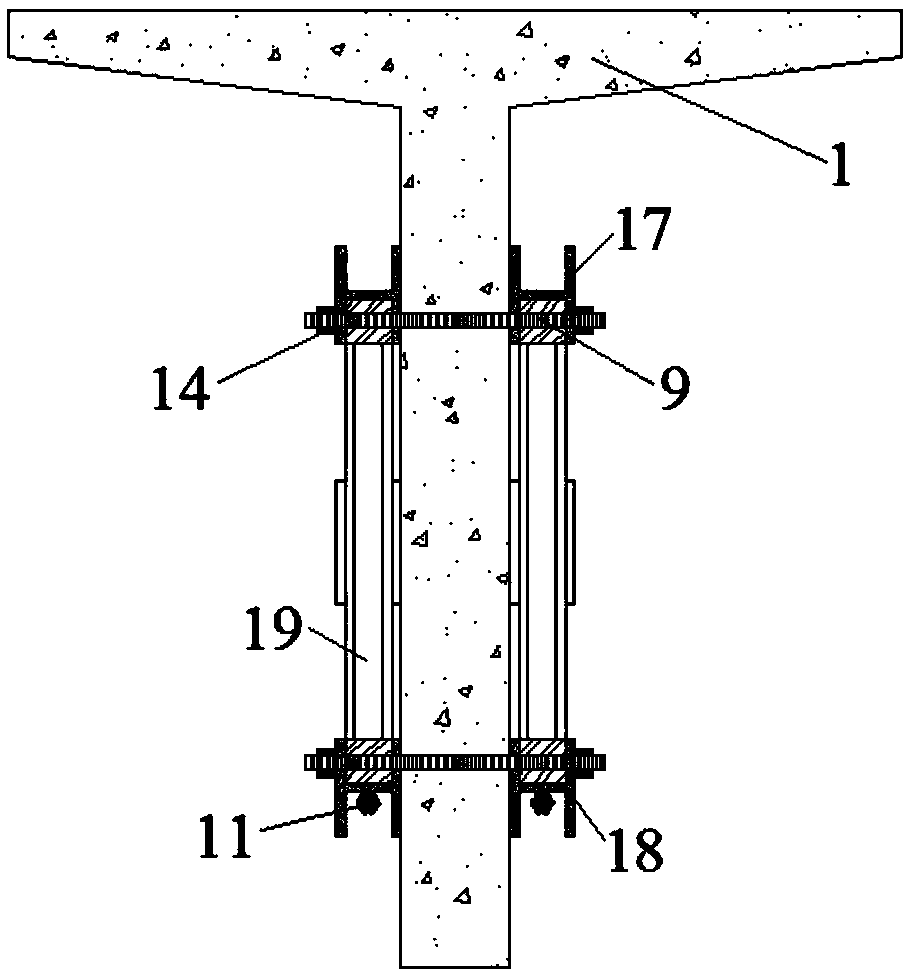

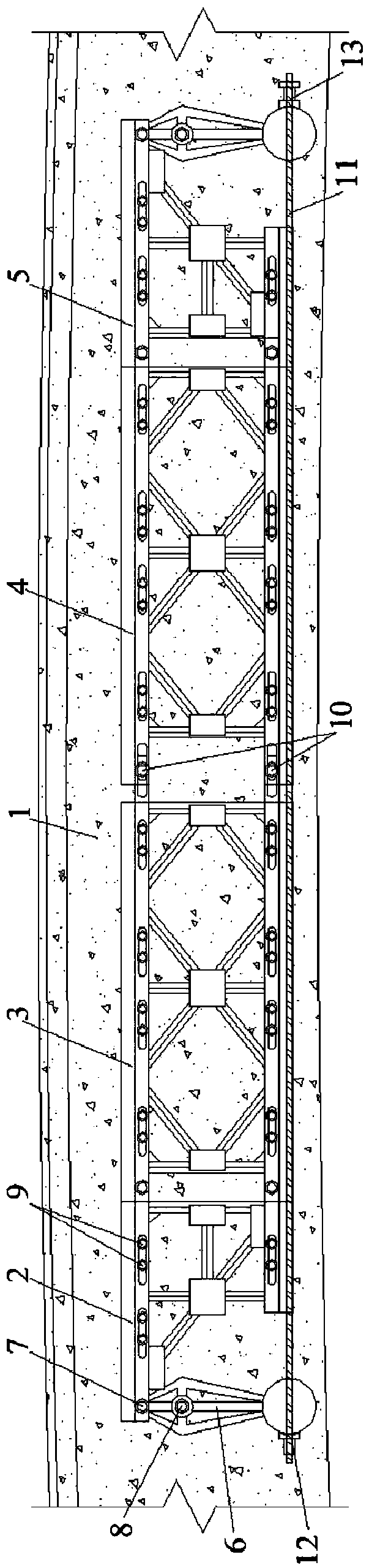

[0033] see Figure 1 to Figure 9 , the middle Bailey sheet group of the present embodiment has adopted a pair of Bailey sheet, can adopt multiple pairs of Bailey sheet as the middle Bailey sheet group according to need during actual use. For ease of description, in this embodiment, the front-end Baileys are called No. I Baileys 2, the tail Baileys are called No. IV Baileys 5, and the Baileys near the front Baileys in the middle Bailey group are One piece is called No. Ⅱ Bailey piece 3, and the other piece is called No. Ⅲ Bailey piece 4. In addition, in order to distinguish from the names, the anchor bolts used to fix the stiffeners, the anchor bolts used to fix each Bailey sheet and the anchor bolts used to connect the middle two Bailey sheets are called the first anchor bolt 8, respectively. The second anchor bolt 9 and the third anchor bolt 10 .

[0034] The components of the Bailey beam are fabricated in the factory in advance, and assembled and hoisted on site. exist f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com