Fixed hoisting bracket device for pushing steel box girder and construction method thereof

A technology of jacking construction and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of poor process promotion, large working space requirements, and increased demand, and achieves convenient assembly and steel saving. Structural processing, fast lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

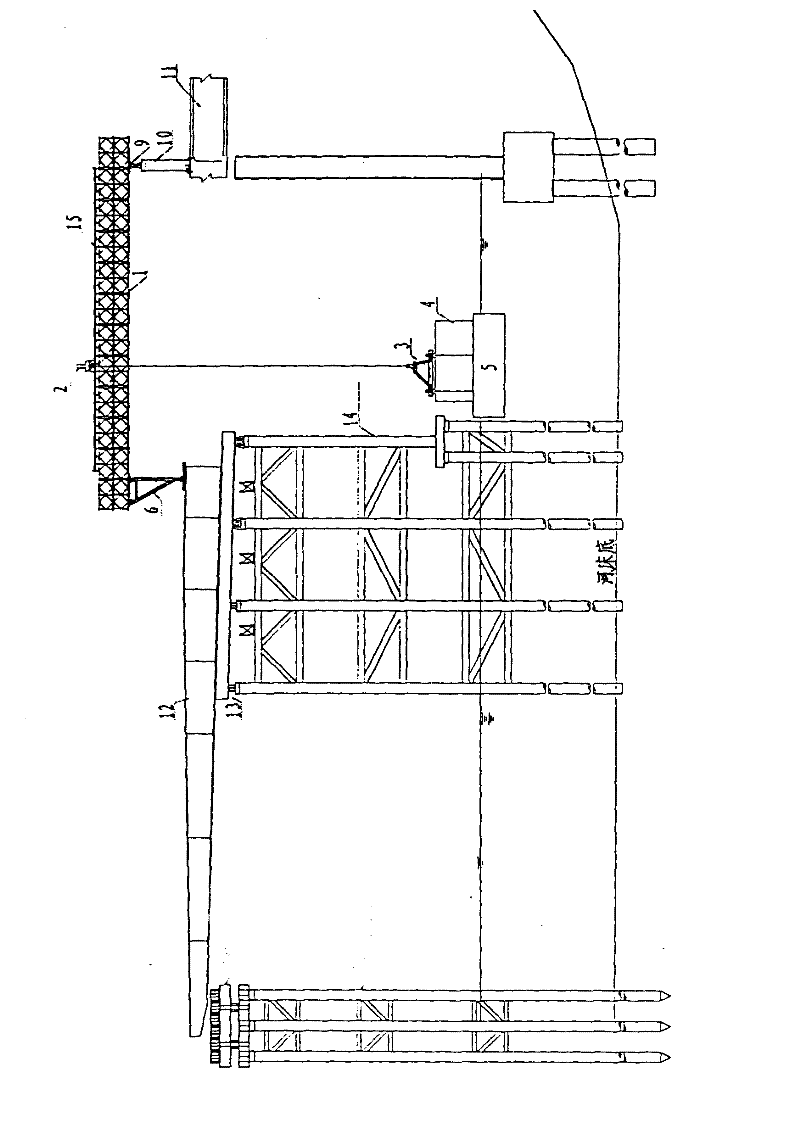

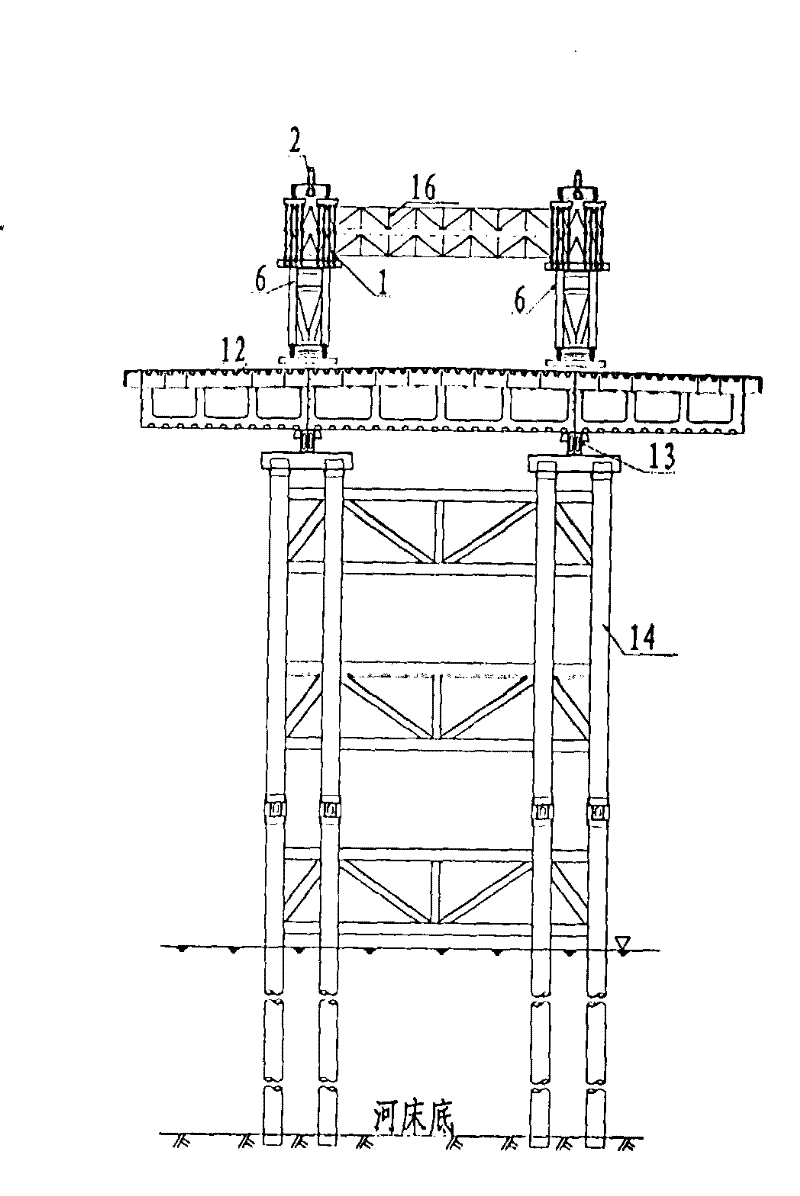

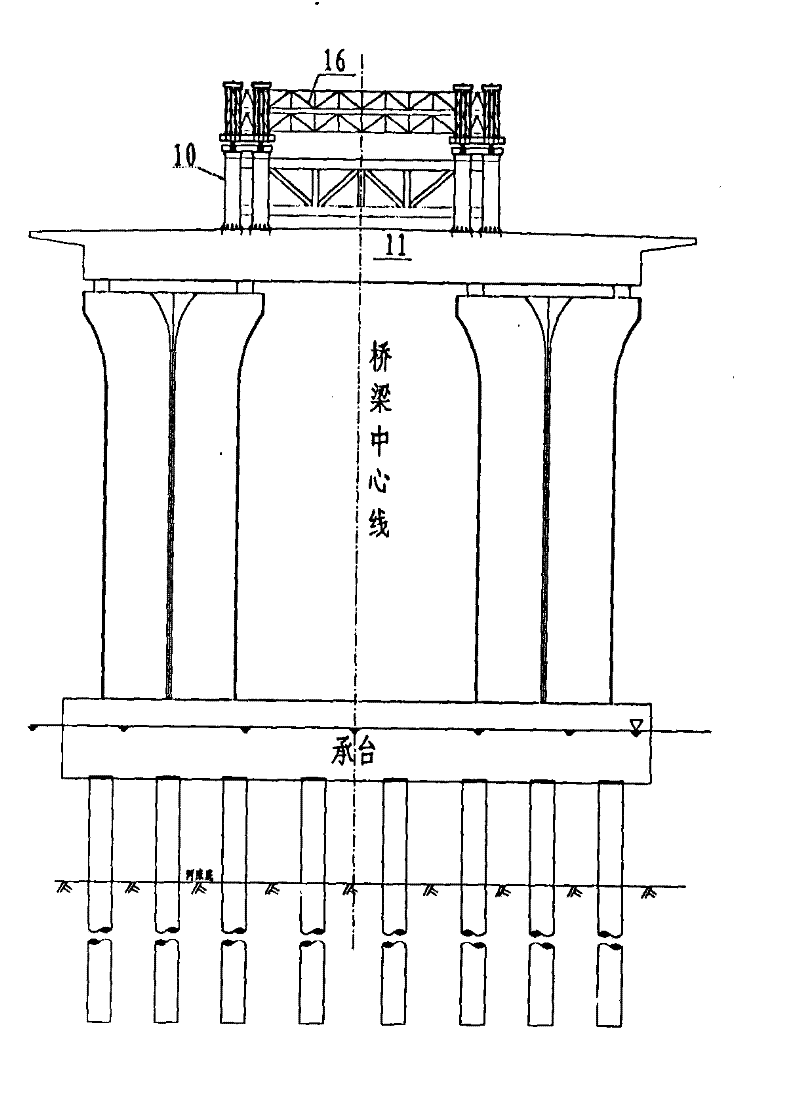

[0016] Referring to the accompanying drawings, its structure is to install a lifting system 2 on the main beam 1 of the fixed lifting bracket, the lifting system 2 is on the lifting system slideway 15, the lifting system 2 is connected to the lifting shoulder beam 3, and the beam section 4 to be lifted is placed on the beam transporting ship 5 Above, the front outrigger 6 is supported on the front outrigger base 7, the friction coefficient between the front outrigger base 7 and the slideway 8 is smaller than the friction coefficient between the guide beam and the erected beam section 12 and the slideway 8, and the rear support The leg column 10 is connected under the hinge seat 9 of the rear outrigger, and the rear outrigger column 10 is supported and fixed on the poured beam section 11. The assembly platform slideway 13 is on the assembly platform 14 to fix the gap between the main beams 1 of the lifting bracket. The horizontal connection structure 16 is a horizontal connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com