Simply supported steel truss girder horizontal construction structure and its construction method

A construction method and technology of steel truss girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of large impact on transportation, and achieve the effect of saving investment, simplifying design, and facilitating design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in combination with specific embodiments.

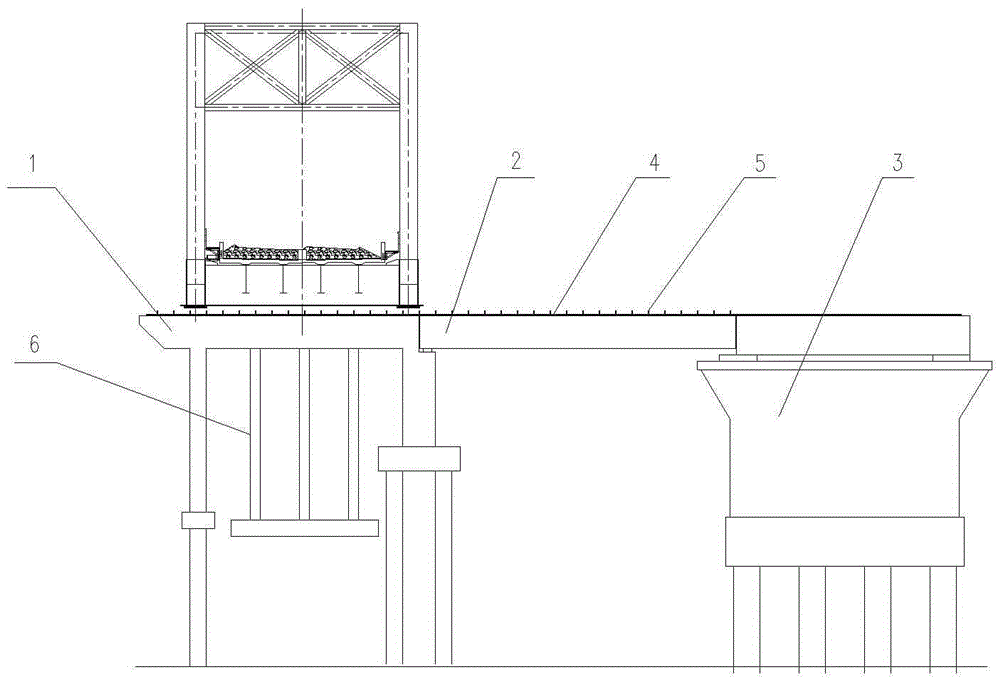

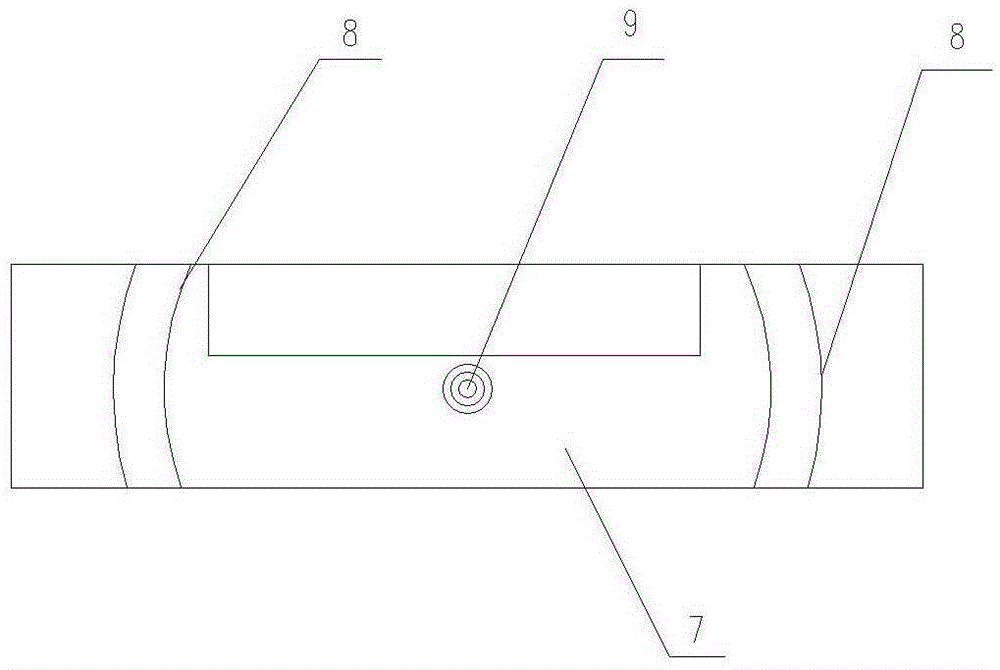

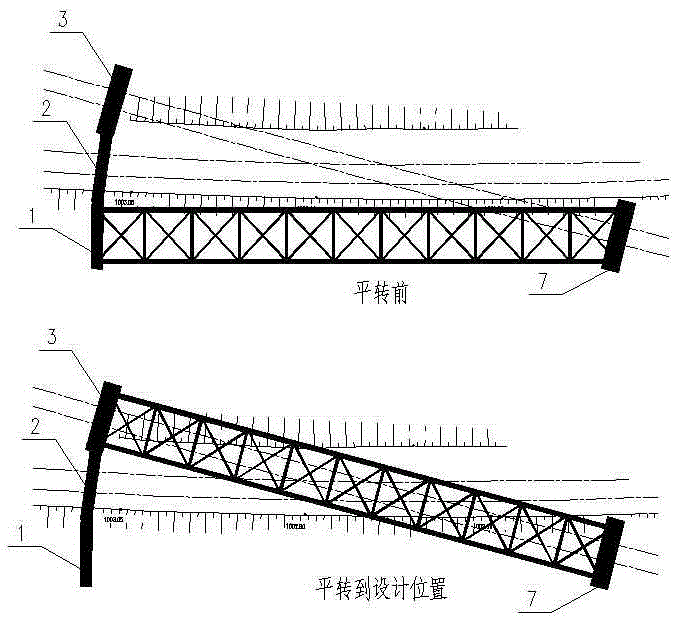

[0031] The simply supported steel truss girder horizontal rotation construction structure involved in the present invention is suitable for the construction situation of simply supported steel truss girders spanning existing railways or highways. The permanent piers supporting the steel truss beams are respectively the permanent piers 7 at the rotating center end and the permanent piers 3 at the sliding end. A temporary pier 1 is arranged on the same side of the permanent pier 7 at the rotating center end of the existing railway or highway, and the straight-line distance from the temporary pier 1 to the permanent pier 7 at the rotating center end and the straight-line distance from the permanent pier 3 at the sliding end to the permanent pier 7 at the rotating center end same. A track beam 2 is erected between the temporary pier 1 and the permanent pier 3 at the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com