Anti-cracking protective mortar for roof waterproof layer

A waterproof layer and mortar technology, which is applied in the field of protective mortar, can solve the problems of short service life, waterproof layer tearing, roof water seepage, etc., and achieve the effect of improving durability and service life, preventing waterproof layer tearing, and small crack width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

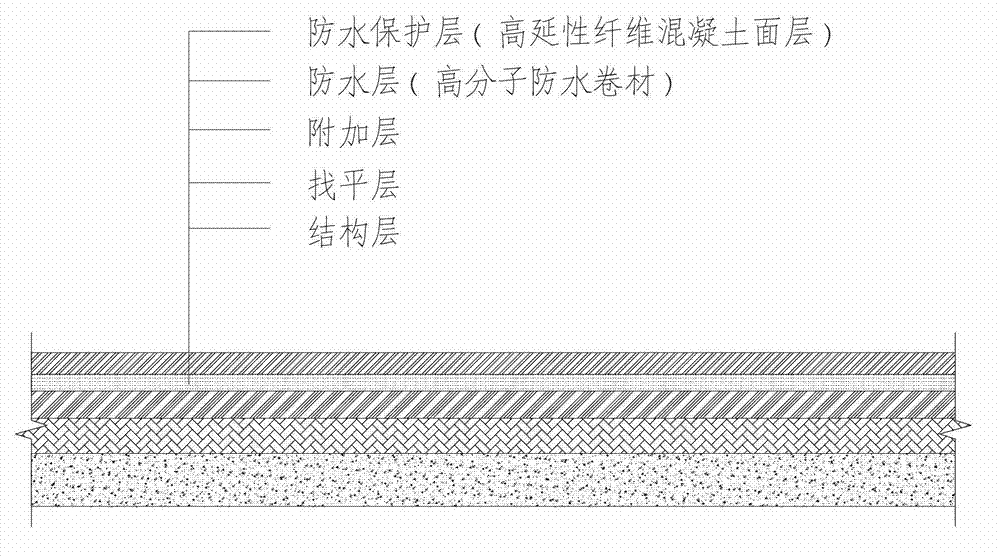

Image

Examples

Embodiment 1

[0015] Following the technical solution of the present invention, the components of the anti-crack protective mortar of the roof waterproof layer of this embodiment are cement, fly ash, silica fume, sand, PVA fiber, water reducing agent and water, wherein, by mass percentage, Cement: fly ash: silica fume: sand: water = 1: 0.9: 0.1: 0.76: 0.58; based on the total volume of cement, fly ash, silica fume, sand and water mixed uniformly, PVA fiber (polyethylene Alcohol fiber) volume content is 1.5%; the addition of water reducer is 0.8% of the total amount of fly ash and cement. Among them: the maximum particle size of sand is 1.26mm; the length of PVA fiber is 6-12mm, the diameter is more than 26μm, the tensile strength is more than 1200MPa, and the elastic modulus is more than 30GPa; the cement is P.O.52.5R Portland cement; The coal ash is Class I fly ash; the silica fume has an ignition loss of 5%, a silicon dioxide content of 88%, and a specific surface area of 18,000m 2 / kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com