Anti-seismic prestressed precast beam

A prefabricated beam and prestressing technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of poor ductility in the plastic hinge area, poor energy dissipation of plastic hinges, and excessive crack width, and achieve the energy dissipation capacity of beam ends. Improve, improve shear strength, improve the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

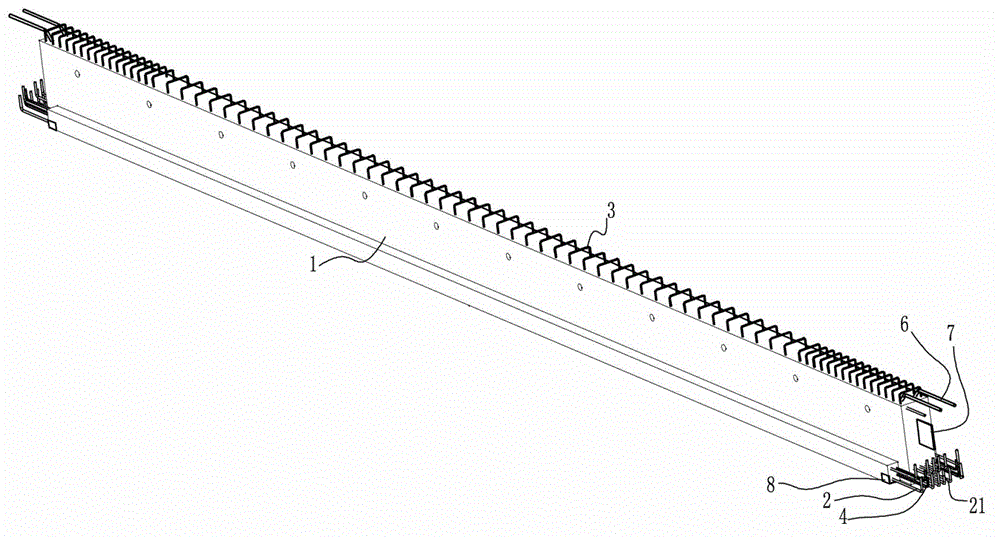

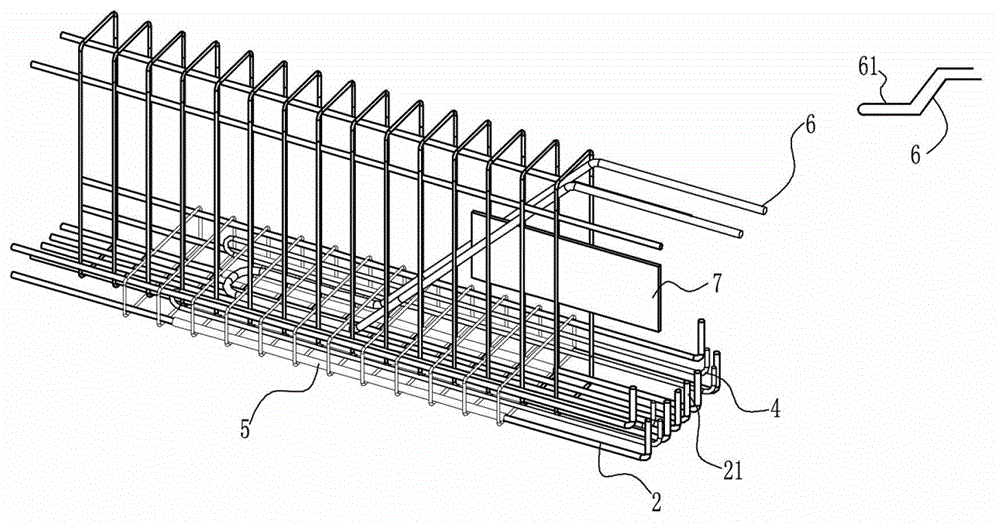

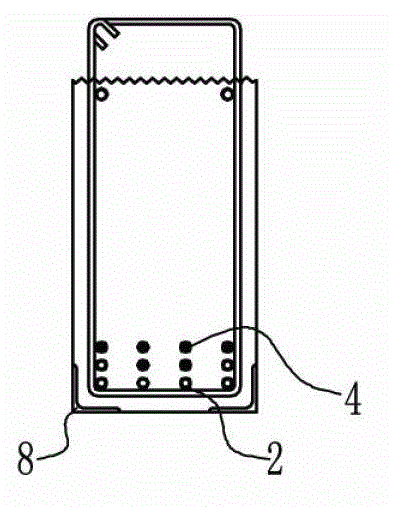

[0022] see Figure 1 to Figure 3 , a kind of anti-seismic prestressed prefabricated beam provided by the present invention includes a beam body 1 and a prestressed steel strand 2 embedded in the beam body 1 as a main reinforcement, a stirrup 3 and an additional reinforcement 4, and the stirrup The tendons 3 protrude from the upper surface of the beam body 1 for a certain length, and the part of the steel strand 2 is covered with a certain length of sleeve 5 at the end of the beam body 1, and the sleeve 5 is embedded in the end of the beam body 1 , the additional rib 4 is embedded in the lower part of the end of the beam body 1, and the additional rib 4 protrudes from the end of the beam body 1 by a certain length. The invention adds additional ribs 4 near the steel strand 2 at the end of the beam body 1 to increase the crack resistance of the end of the beam body 1 and can effectively control the crack width. The bushing 5 in the present invention can release part of the stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com