Anchored ribbed type connecting device for prestressed concrete and steel tower section of wind power combined tower

A connecting device and prestressing technology, applied in wind turbine components, wind energy power generation, wind turbines, etc., can solve the problems of excessive local compression and the difficulty of concrete crack width to meet the requirements of the specification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

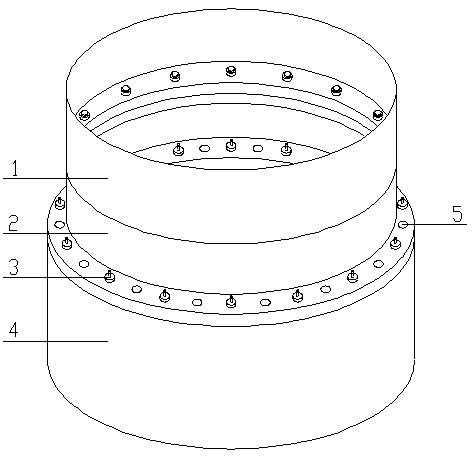

[0020] Such as figure 1 As shown, a connection device 2 is provided between the upper steel tower section 1 and the lower concrete tower section 4 .

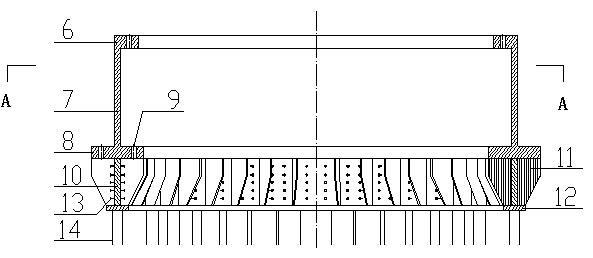

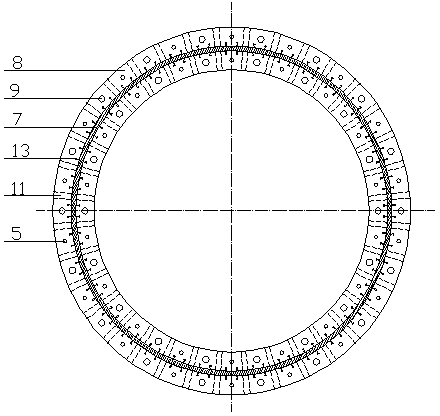

[0021] Such as figure 2 , image 3 As shown, a wind power composite tower anchor bolt ribbed prestressed concrete and steel tower section connection device, including the upper and lower two connecting steel cylinders with coincident central axes and the same radius, the top of the upper connecting steel cylinder 7 is connected by The mechanism is that the high-strength bolts 15 are connected with the upper steel tower section 1; the lower connecting flange 8 is installed between the upper connecting steel cylinder 7 and the lower connecting steel cylinder 10, and the upper connecting steel cylinder wall and the lower connecting steel cylinder wall are located Connect the middle ring surface between the outer ring surface of the lower flange plate 8 and the inner ring surface, and install a horizontal ring plate 12 on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com