Method for regenerating aggregate concrete from steel fibre rubber granule modified asphalt

A technology of rubber granules and recycled aggregates, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of less than 30% recycling rate, non-degradable waste rubber, efficient energy waste, etc. Achieve the effect of improving energy consumption, reducing thermal conductivity and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

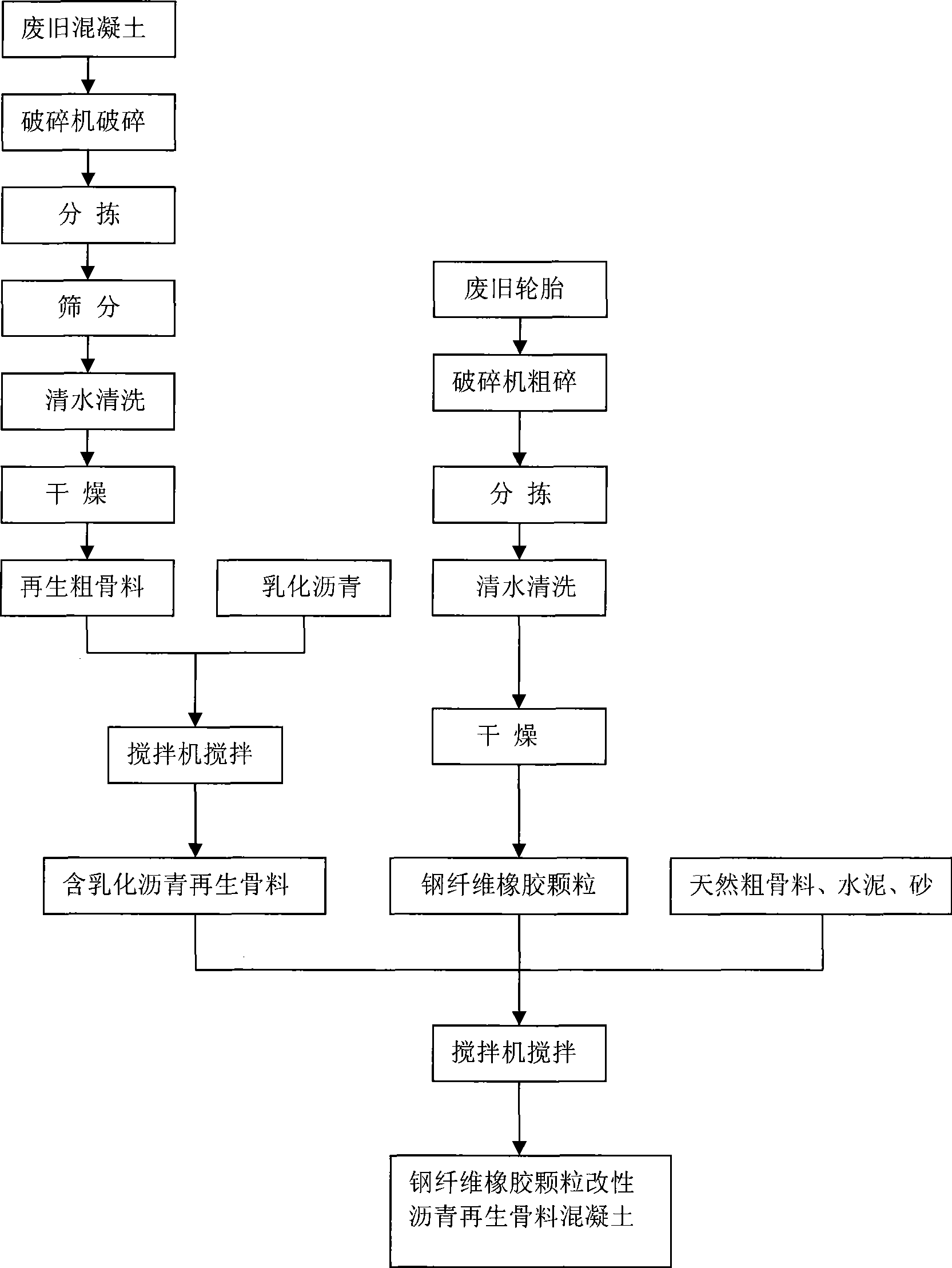

[0027] The implementation steps of the present invention are as follows:

[0028] (1) The recycled aggregate is crushed by the waste concrete through the crusher, and the debris other than the concrete is sorted, and then passed through a mesh screen to screen out the recycled coarse aggregate with a size between 4.00mm and 30.00mm, and clean it After washing, let it dry naturally.

[0029] (2) Put the emulsified asphalt and the dried recycled aggregate into the mixer for stirring, so that the emulsified asphalt is spread on the surface of the recycled aggregate.

[0030] (3) Steel fiber rubber particles are obtained from waste tires through a crusher through coarse crushing, sorting, cleaning, and drying. The size is 1 mesh to 5 mesh, and the length of the steel wire is the natural cut-off length of the crusher.

[0031] (4) Put sand, cement, steel fiber rubber particles, emulsified asphalt recycled aggregates and primary stones into the mixer in proportion to mix evenly, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com