Uplift pile mixed connection structure

A hybrid connection and uplift pile technology, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as the inability to effectively solve the problems of pile head sealing and anti-corrosion, extremely high strength and thickness requirements, and large residual deformation. , to reduce the thickness of the pile head steel plate, increase the contact area and stability, and improve the pull-out performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

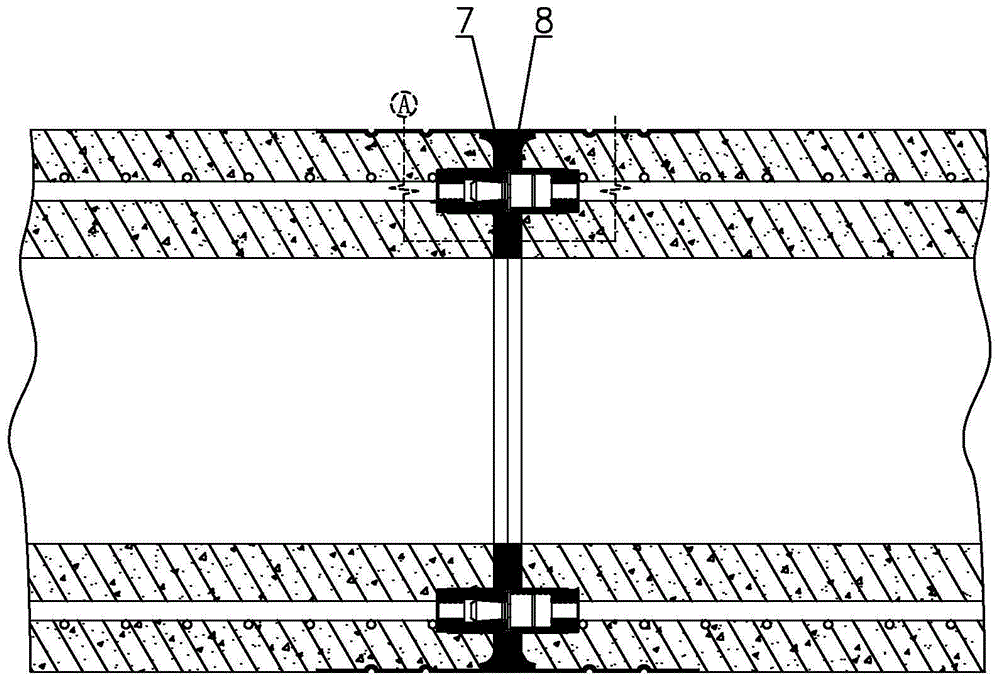

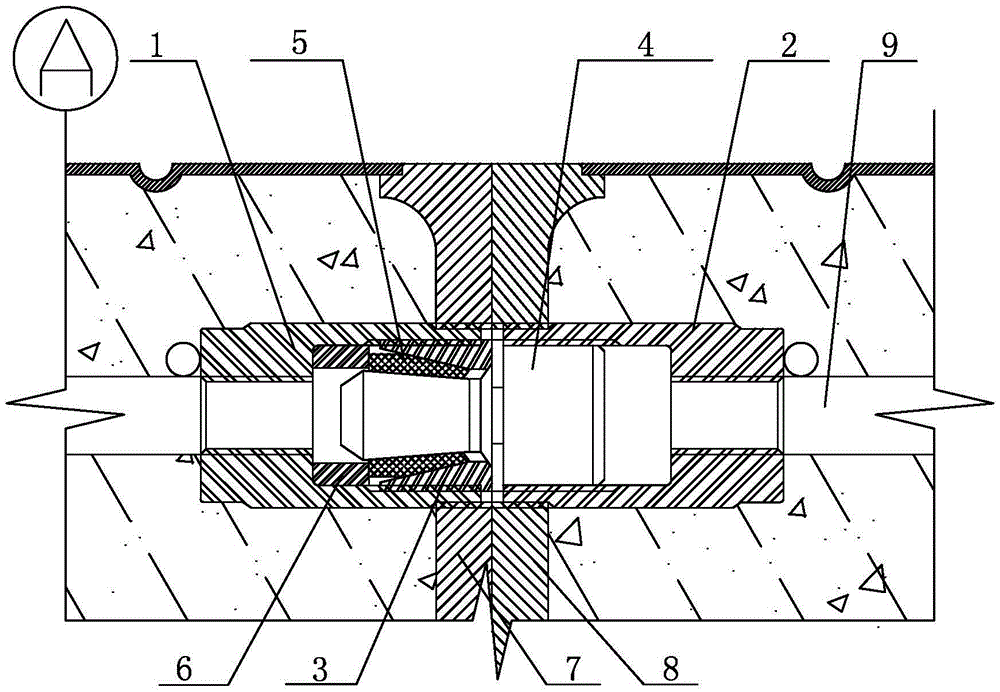

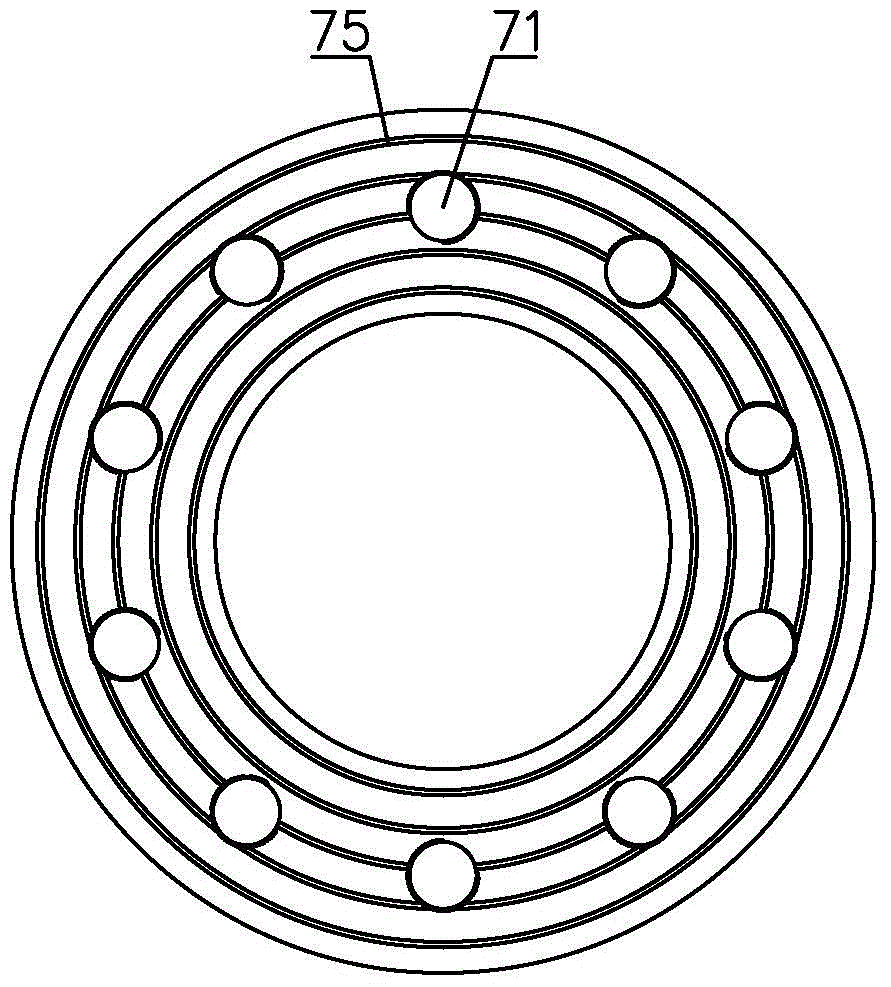

[0043] Such as figure 1 and figure 2 As shown, a hybrid connection structure of uplift piles includes pile head protection sleeve I7, pile head protection sleeve II8 and plug joints. The plug joints include sleeve-shaped fixed positioning sleeves I1 and fixed positioning sleeves II2. The bottoms of the fixed positioning sleeve I1 and the fixed positioning sleeve II2 are provided with a limit end 11 that can limit the end of the main rib in it, and the fixed positioning sleeve I1 and the fixed positioning sleeve II2 are connected with the main rib. The pile head protection sleeve I7 is provided with a fixing hole I71, and the corresponding position of the pile head protection sleeve II8 is provided with a fixing hole II (unlabeled, the specific setting method is as the fixing hole I71), and the opening end of the fixed positioning sleeve I1 Fixed at the fixing hole I71, the opening end of the fixed positioning sleeve II2 is fixed at the fixing hole II, the fixed positionin...

Embodiment 2

[0054] Such as Figure 12 to Figure 14 As shown, the difference between this embodiment and Embodiment 1 is that the pile head protection sleeve I7 and the pile head protection sleeve II8 are fixed by full welding at the edges, no annular groove is provided on the end surface, and the edge of the end plate 72 is provided with Solder groove 74. Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com