Conductive super high ductility cement-based composite material and preparation method thereof

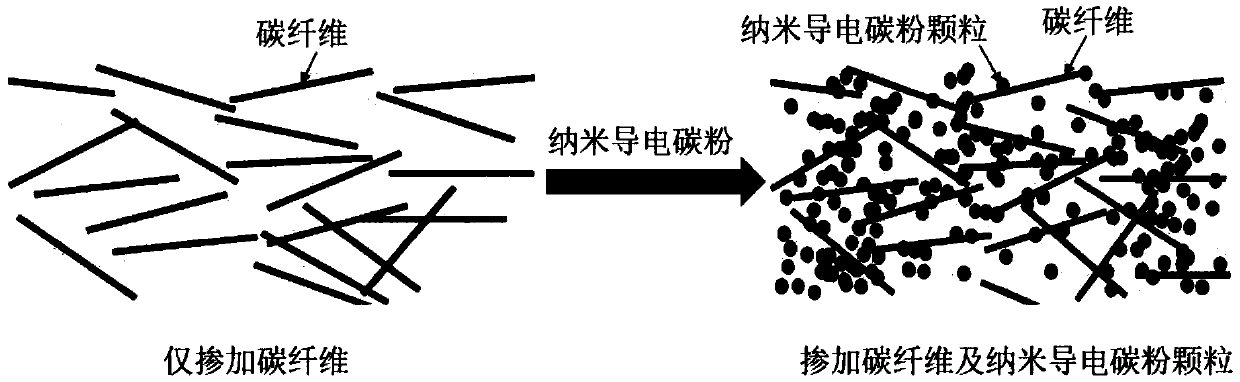

A composite material and cement-based technology, which is applied in the field of construction engineering, can solve the problems of cracking of main cracks, reducing the continuity and stability of the conductivity of cement-based materials, etc., to achieve strong power-on and heating capabilities, continuous and stable conductive network connection reliability, Effect of improving electrical conductivity and crack control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

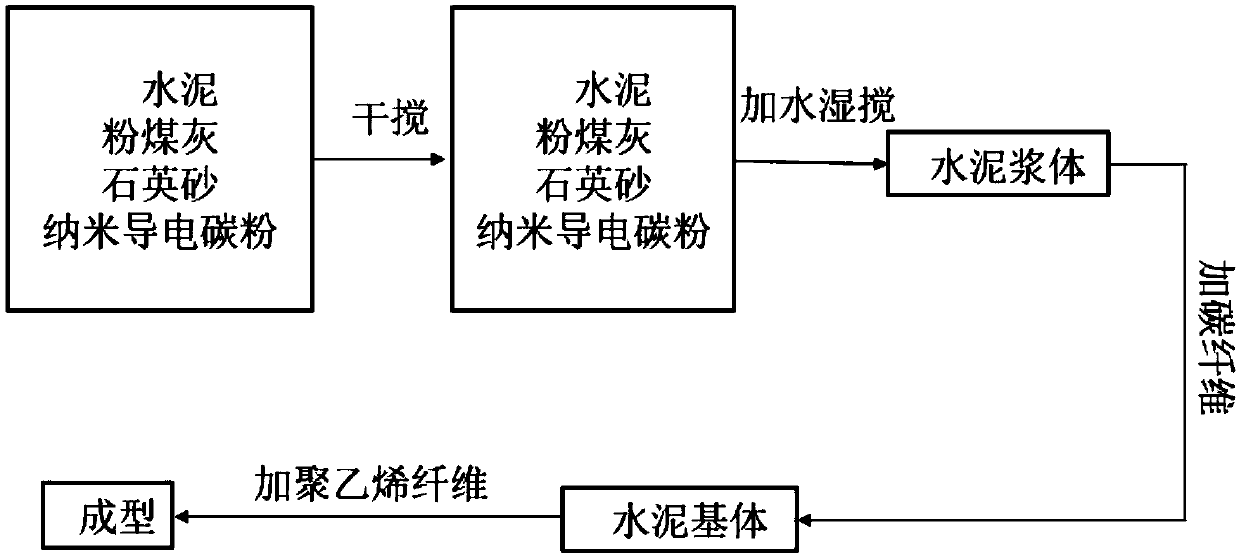

Method used

Image

Examples

Embodiment 1

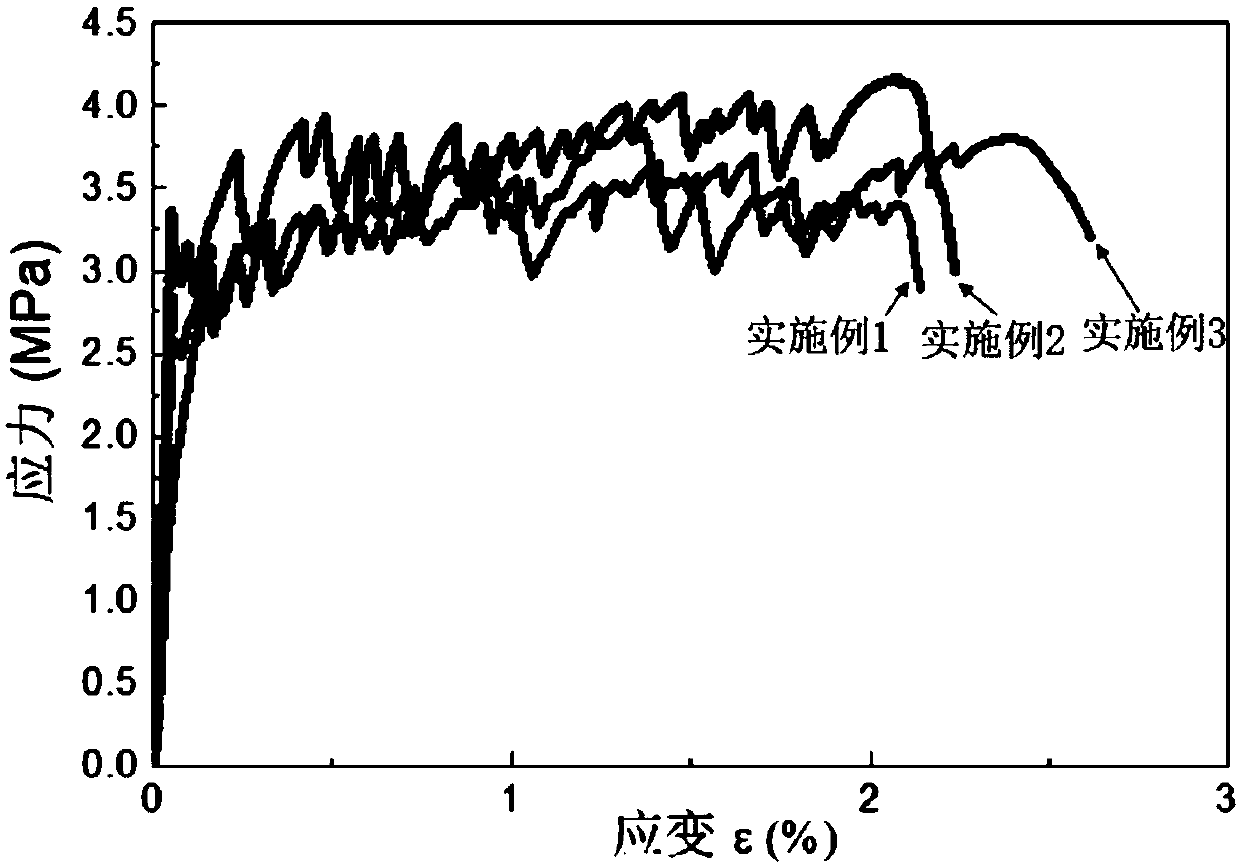

[0040] This implementation example is used to test the uniaxial tensile properties of the prepared conductive ultra-high ductility cement-based composite material, and includes the following components in parts by weight:

[0041]

[0042]

[0043] It also includes polyethylene fibers with a volume content of 1.5% and carbon fibers with a volume content of 0.5%.

[0044] The cement is ordinary Portland cement or composite Portland cement, its 28-day compressive strength ≥ 52.5MPa, 28-day flexural strength ≥ 7.0MPa, specific surface area ≥ 300m 2 / kg.

[0045] Fly ash is a first-class fly ash with a specific surface area ≥ 700m 2 / kg, the density is 2.6g / cm 3 .

[0046] Quartz sand is superfine quartz sand, its specifications are 70-110 mesh, and the particle size is 0.1-0.15mm.

[0047] The particle size of the nano conductive carbon powder is 9-20nm, and the resistivity is 0.5-1.0Ω·m.

[0048] The length of the polyethylene fiber is 6mm-12mm, the diameter is 12-39μ...

Embodiment 2

[0055] This implementation example is used to test the uniaxial tensile properties of the prepared conductive ultra-high ductility cement-based composite material, and includes the following components in parts by weight:

[0056]

[0057] Also included are polyethylene fibers at a volume content of 1.7% and carbon fibers at a volume content of 0.8%.

[0058] The cement is ordinary Portland cement or composite Portland cement, its 28-day compressive strength ≥ 52.5MPa, 28-day flexural strength ≥ 7.0MPa, specific surface area ≥ 300m 2 / kg.

[0059] Fly ash is a first-class fly ash with a specific surface area ≥ 700m 2 / kg, the density is 2.6g / cm 3 .

[0060] Quartz sand is superfine quartz sand, its specifications are 70-110 mesh, and the particle size is 0.1-0.15mm.

[0061] The particle size of the nano conductive carbon powder is 9-20nm, and the resistivity is 0.5-1.0Ω·m.

[0062] The length of the polyethylene fiber is 6mm-12mm, the diameter is 12-39μm, the elastic ...

Embodiment 3

[0069] This implementation example is used to test the uniaxial tensile properties of the prepared conductive ultra-high ductility cement-based composite material, and includes the following components in parts by weight:

[0070]

[0071] It also includes 2% polyethylene fiber by volume and 1% carbon fiber by volume.

[0072] The cement is ordinary Portland cement or composite Portland cement, its 28-day compressive strength ≥ 52.5MPa, 28-day flexural strength ≥ 7.0MPa, specific surface area ≥ 300m 2 / kg.

[0073] Fly ash is a first-class fly ash with a specific surface area ≥ 700m 2 / kg, the density is 2.6g / cm 3 .

[0074] Quartz sand is superfine quartz sand, its specifications are 70-110 mesh, and the particle size is 0.1-0.15mm. The particle size of the nano conductive carbon powder is 9-20nm, and the resistivity is 0.5-1.0Ω·m.

[0075] The length of the polyethylene fiber is 6mm-12mm, the diameter is 12-39μm, the elastic modulus is ≥100GPa, the ultimate tensile s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com