Progressive collapse resistant cold-formed thin-walled profile combined wall and quick field mounting method thereof

A cold-formed thin-walled steel and wall technology, which is applied in the processing of walls, building materials, building components, etc., can solve the problem of column damage, continuous collapse of the entire wall, and floor beam layout limited by wall columns Plane location and other issues to achieve the effect of increasing safety and reliability, avoiding continuous collapse, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

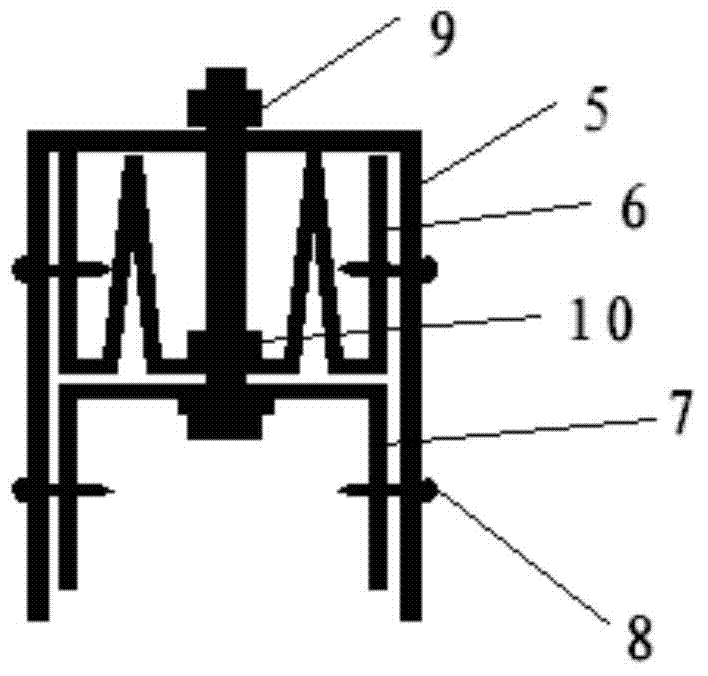

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

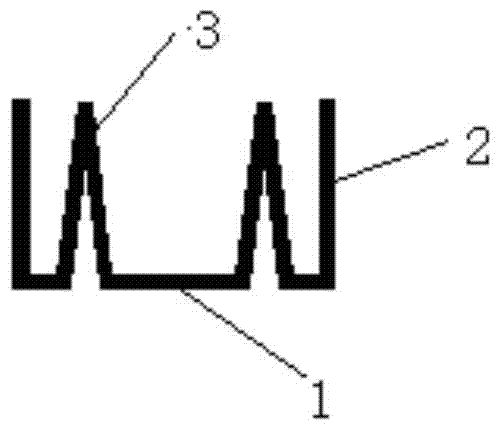

[0030] The invention relates to a cold-formed thin-walled steel composite wall resistant to continuous collapse, which includes a combined upper guide rail, a lower guide rail, a wall column and a wall plate; The ribbed U-shaped cold-formed thin-walled steel keel and the outer frame U-shaped cold-formed thin-walled steel keel can transmit the vertical load inside the wall. in:

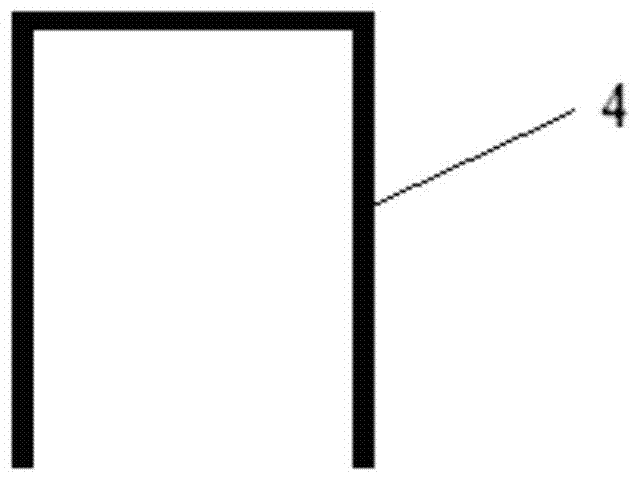

[0031] Conventional U-shaped cold-formed thin-walled steel keel (hereinafter referred to as U-shaped keel / conventional U-shaped keel) is a component commonly used in the prior art as the guide rail of the upper / lower wall column of the cold-formed steel composite wall. In the prior art, it is fixedly connected with the flange of the C-shaped keel column at equal intervals to form a light steel skeleton.

[0032] Web ribbed U-shaped cold-formed thin-walled steel keel (hereinaft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com