Prefabricated assembly type bolted connection reinforced concrete box-girder

A steel-concrete composite beam and prefabricated assembly technology, which is applied to structural elements, building components, and long-strip structural components for load-bearing, etc., can solve problems such as difficult construction, slow construction efficiency, and complicated design, and reduce welding. Work and last-shift work, convenient construction, and the effect of improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with accompanying drawing.

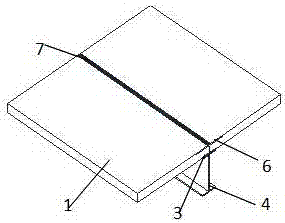

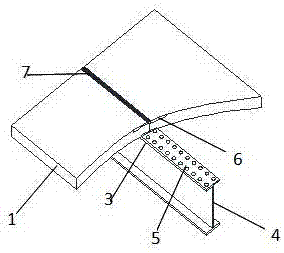

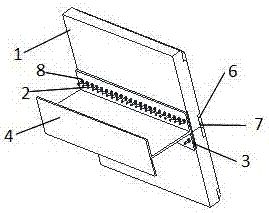

[0021] refer to Figure 1-4 , a prefabricated assembled bolt-connected steel-concrete composite beam, comprising a precast concrete slab 1, the precast concrete slab 1 is installed on a steel beam 4, a thin-walled steel plate 3 is pre-embedded at the bottom of the precast concrete slab 1, and a hole is opened on the thin-walled steel plate 3, The shear bolt 2 passes through the hole reserved in the thin-walled steel plate 3 and is welded with it. The shear bolt (2) is installed in the hole 5 reserved in the flange of the steel beam. ) is welded into a pre-embedded part, which is pre-embedded at both ends of the precast concrete slab 1 as a whole, and the adjacent pre-embedded steel plates are welded by using the butt weld 7 .

[0022] The mid-span of the prefabricated concrete slab 1 pre-embeds the shear bolts 2, whose positions are consistent with those of the reserved holes 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com