Pre-stressing-force fabricated concrete-frame-joint connecting structure and construction method thereof

A node connection and prefabricated concrete technology, which is applied in truss structures, building structures, protective buildings/shelters, etc., can solve the problems of difficult construction of dry connection nodes, poor structural integrity, and complicated construction process. Achieve the effects of enhancing the ability to resist progressive collapse, improving integrity, and improving shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

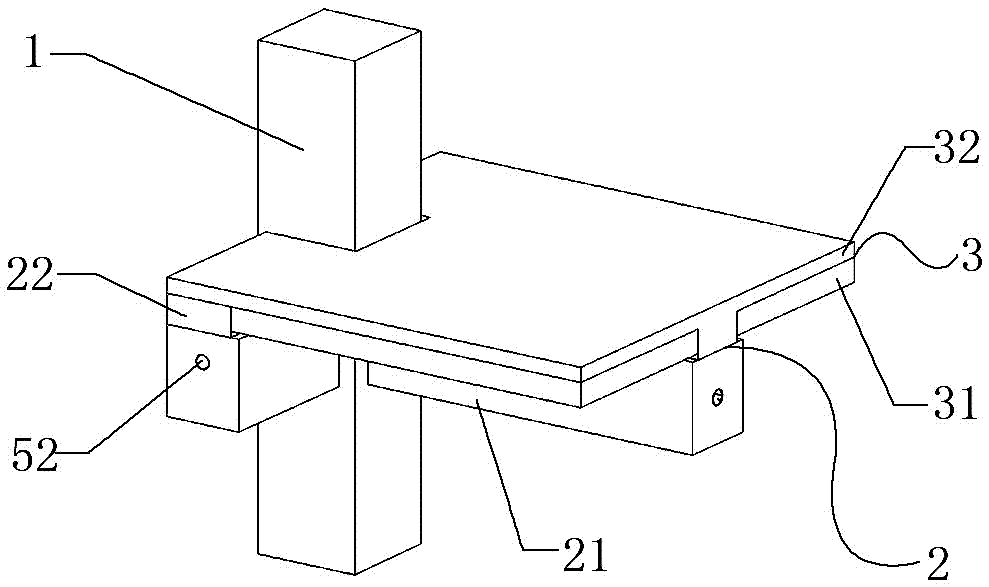

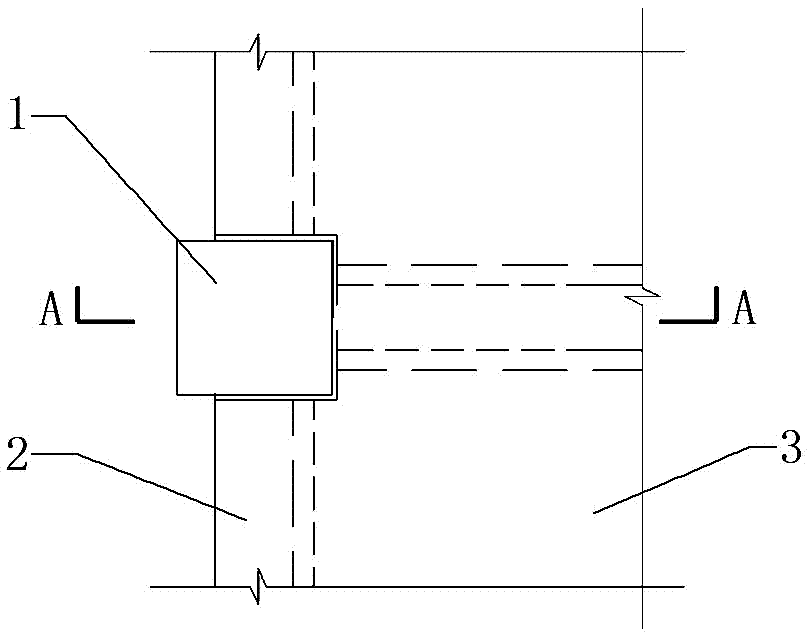

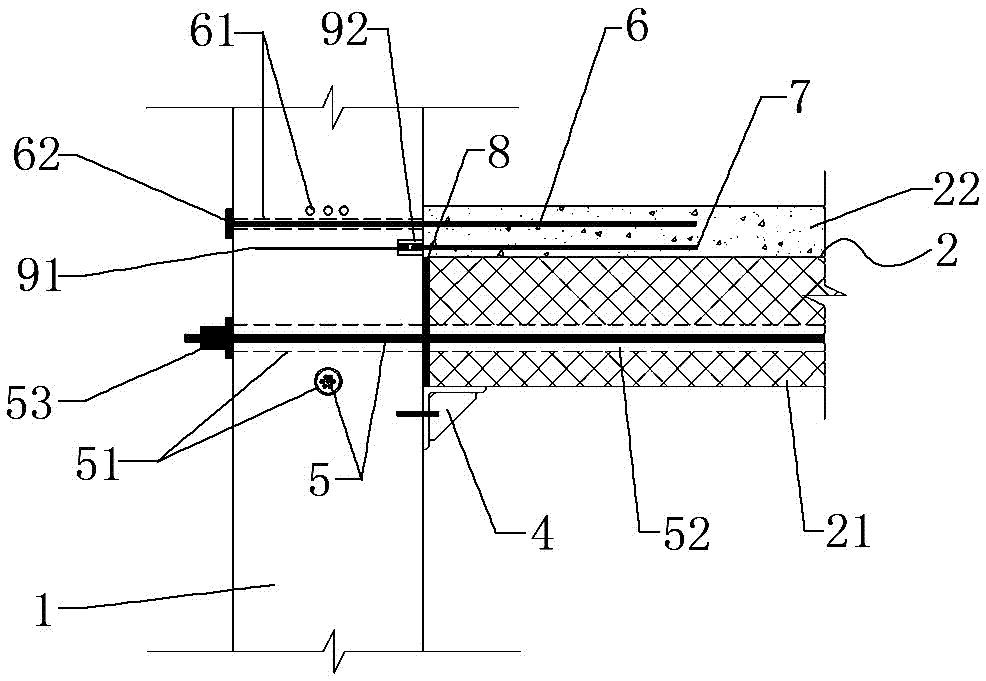

[0046] Such as Figure 1 to Figure 3 As shown, the prestressed assembled concrete frame node connection structure of the present invention includes a precast concrete column 1, a precast concrete composite beam 2, a composite floor 3, and post-tensioned prestressed steel bars connecting the precast concrete column 1 and the precast concrete composite beam 2 Bundle 5, bending energy dissipation steel bar 6 and shear high-strength steel bar 7 located in the post-casting layer on the upper part of the precast concrete composite beam 2, the post-casting layer 22 of the beam of the precast concrete composite beam 2 and the post-casting layer of the composite floor 3 32 are poured in one piece. The precast concrete column 1 is a side column, and the side wall of the precast concrete column 1 is provided with a temporary support 4, the temporary support 4 is a corbel, and the other side supports the beam bottom of the precast concrete composite beam 2.

[0047] Such as figure 1 As ...

Embodiment 2

[0060] Such as Figure 4 to Figure 9 As shown, the prestressed assembled concrete frame node connection structure of the present invention includes a precast concrete column 1, a precast concrete composite beam 2, a composite floor 3, and post-tensioned prestressed steel bars connecting the precast concrete column 1 and the precast concrete composite beam 2 Bundle 5, bending energy dissipation steel bar 6 and shear high-strength steel bar 7 located in the post-casting layer on the upper part of the precast concrete composite beam 2, the post-casting layer 22 of the beam of the precast concrete composite beam 2 and the post-casting layer of the composite floor 3 32 are poured in one piece. The precast concrete column 1 is the central column, and the side wall of the precast concrete column 1 is provided with a temporary support 4, which is a corbel, and the other side is supported on the beam bottom of the precast concrete composite beam 2.

[0061] Such as Figure 4 and Fi...

Embodiment 3

[0067] Such as figure 1 , figure 2 and Figure 10 As shown, the prestressed assembled concrete frame node connection structure of the present invention includes a precast concrete column 1, a precast concrete composite beam 2, a composite floor 3, and post-tensioned prestressed steel bars connecting the precast concrete column 1 and the precast concrete composite beam 2 Bundle 5, bending energy-dissipating steel bar 6 and shear high-strength steel bar 7 located in the post-casting layer on the upper part of the precast concrete composite beam 2, the post-casting layer 22 of the beam of the precast concrete composite beam 2 and the post-casting layer of the composite floor 3 32 are poured in one piece. The precast concrete column 1 is a side column, and the side wall of the precast concrete column 1 is provided with a temporary support 4, the temporary support 4 is a corbel, and the other side supports the beam bottom of the precast concrete composite beam 2.

[0068]The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com