Device and method for testing progressive collapse performances of concrete plate-column structure

A technology of plate-column structure and testing device, which is applied to the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of increased bending force and shearing force of plate-column joints, continuous collapse of the range, and joint failure, etc. To achieve the effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

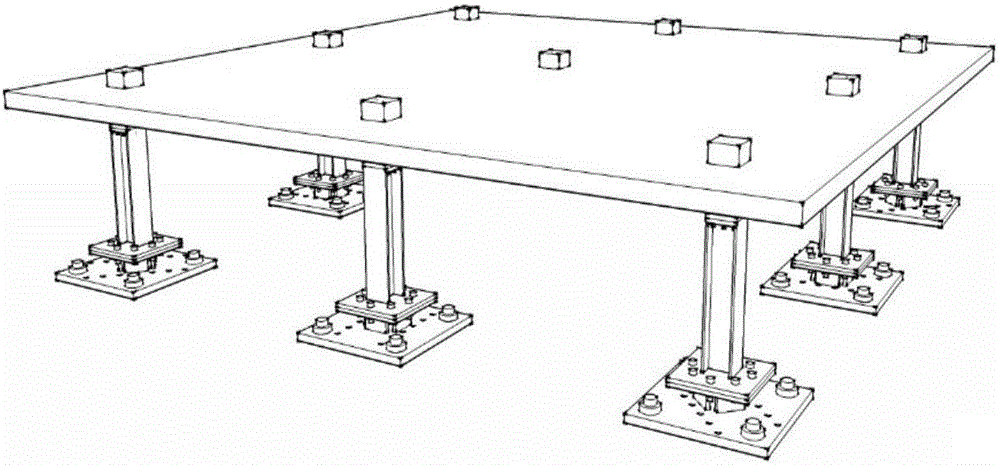

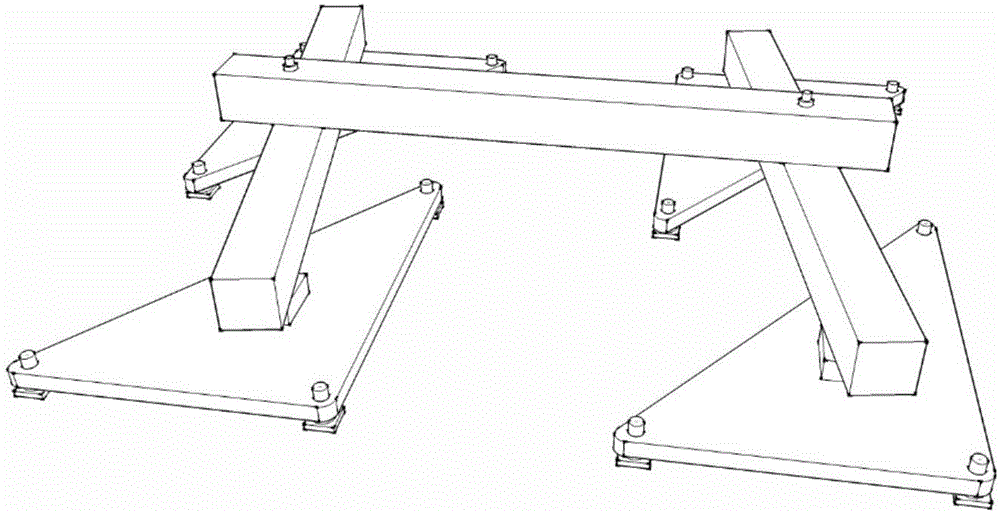

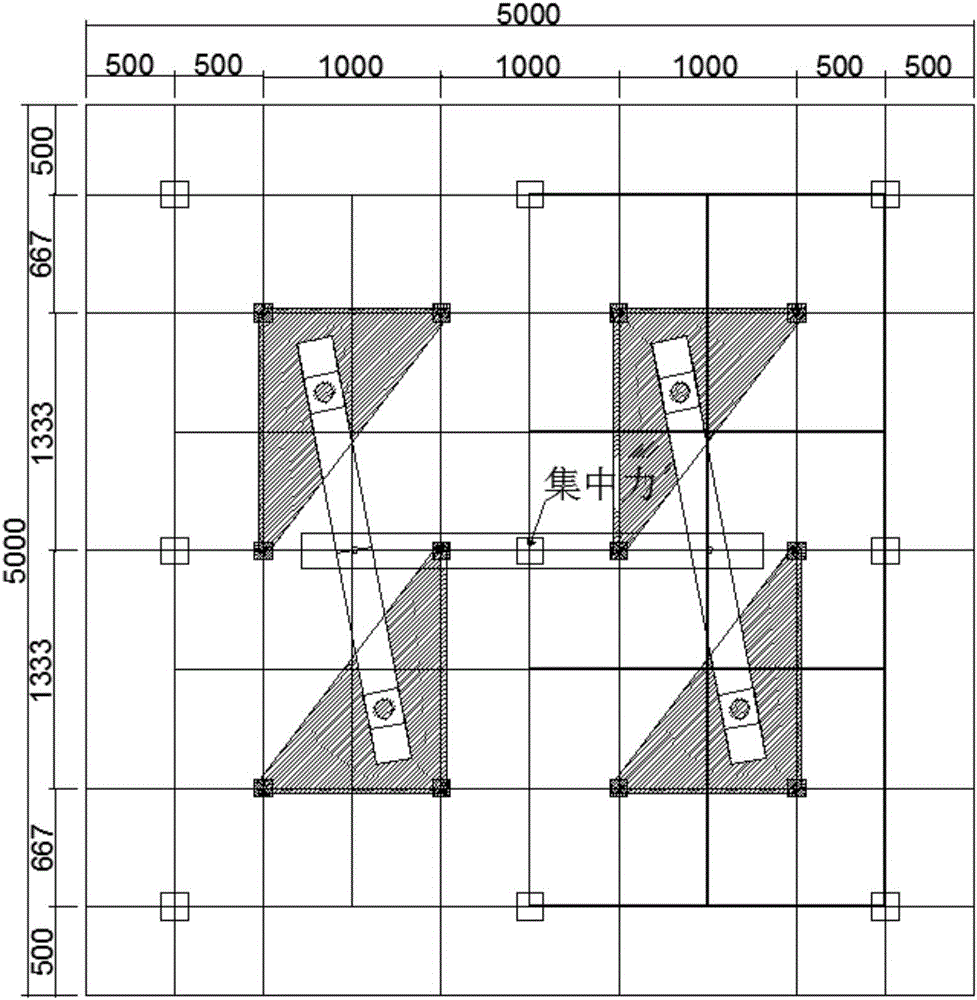

[0032] The technical scheme of the device of the present invention is as figure 2 , 4 Shown, take a slab-column structure test plan as an example to introduce the implementation steps of the present invention in detail:

[0033] (1) When pouring the concrete slab-column structure, firstly reserve a hole in each of the 12 rectangular centers of the concrete slab (such as image 3 ). During the test, 12 bolts are required to fix 12 holes. And fix a small steel plate with a hole in the middle between the nut on the upper part of the bolt and the concrete slab. This avoids direct contact of the triangular steel plate with the concrete slab. The force of the triangular steel plate first acts on the small rectangular steel plate and then is transmitted to the concrete slab, and the small rectangular steel plate has a large bottom area, which can prevent the concrete below it from being crushed due to excessive stress.

[0034](2) Because it is necessary to open a round hole at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com