Assembled composite structure system and implementation method thereof

A combined structure and assembled technology, which is applied to building components, building structures, walls, etc., can solve the problems of heavy welding workload on site, heavy weight of cast-in-place slabs, and large number of rods, so as to save welding work, The effect of reducing construction costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

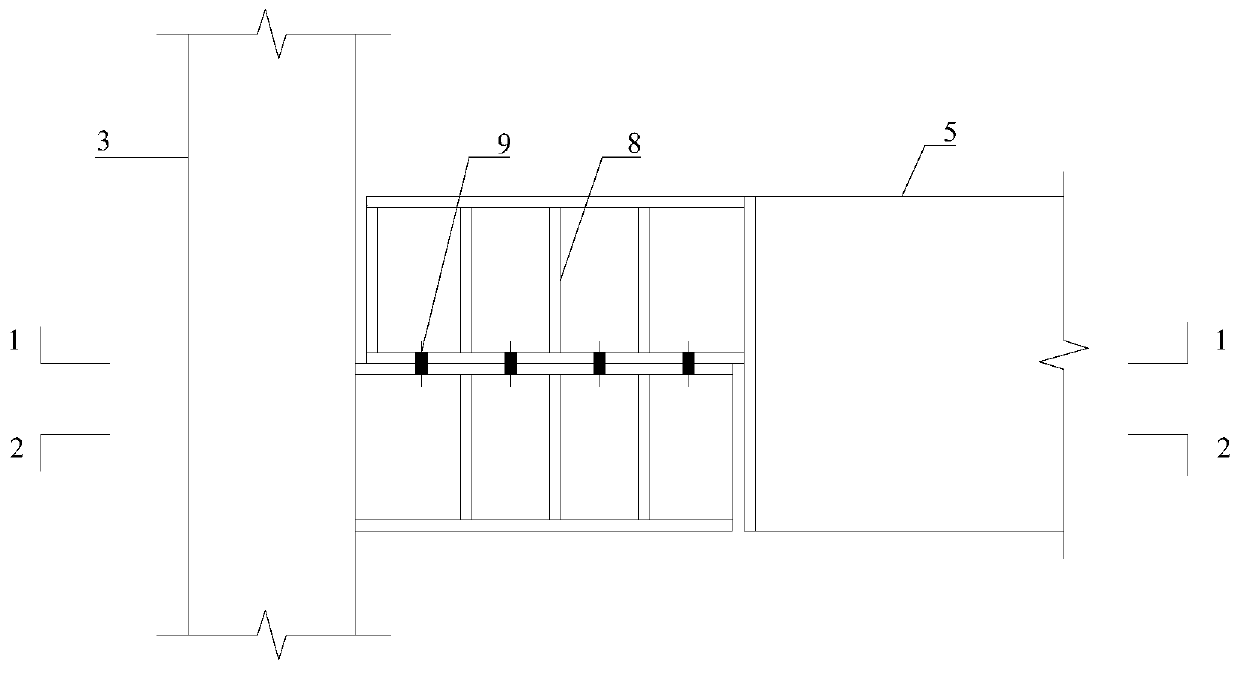

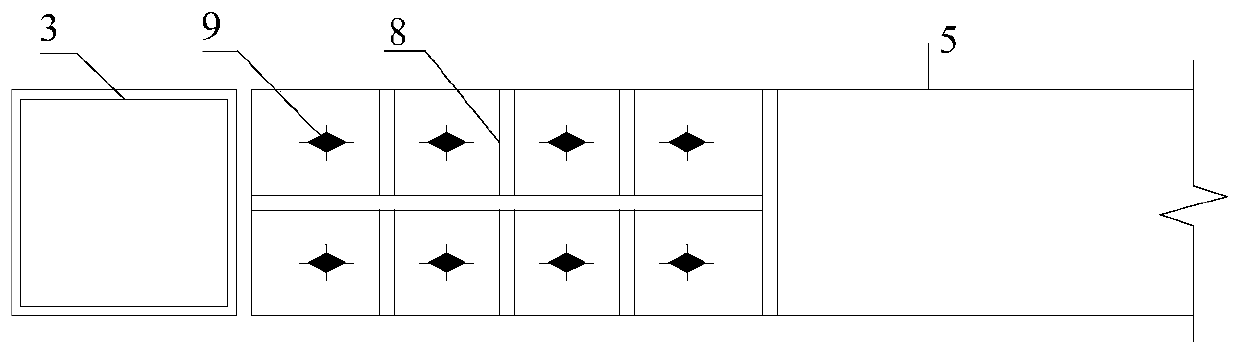

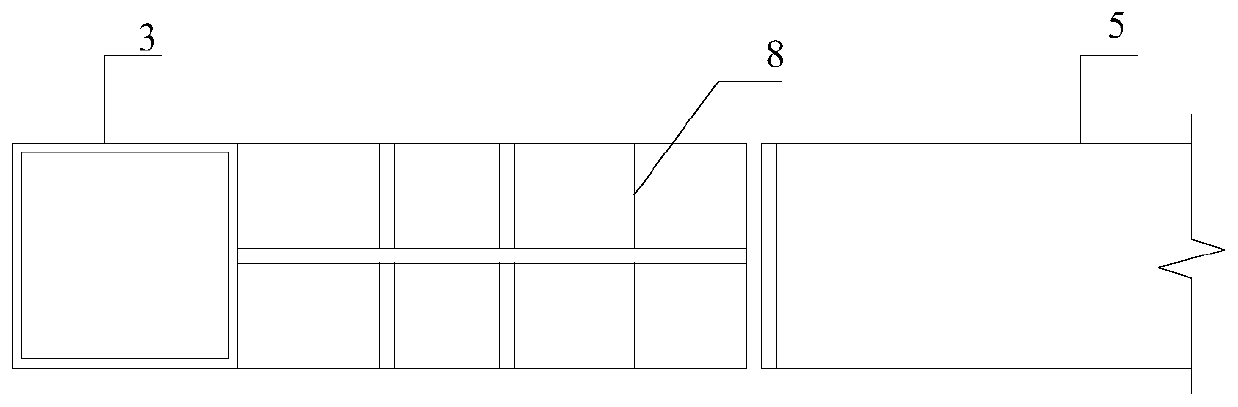

[0029] A prefabricated composite structure system, including load-bearing components, the load-bearing components include truss steel columns, the truss steel columns are arranged in an "L" shape, there are truss column vertical rods 3 in the vertical direction, and the truss column vertical rods 3 are vertically arranged with Prefabricated steel beams 5, so that the projection of the overall bearing member on the horizontal plane is "L"-shaped; 1 and diagonal rods 2 form a truss structure. Such as Figure 4 As shown, the horizontal webs 1 are arranged parallel to each other, and the two ends of the oblique webs 2 between two adjacent horizontal webs 1 are respectively staggered from the two ends of the two horizontal webs 1, so that two adjacent horizontal The diagonal web bar 2 between the web bar 1 and the two horizontal web bars 1 is in a "Z" shape. This structure utilizes structural features to achieve its own stable balance without the need for temporary supports. The...

Embodiment approach

[0038] A method for implementing a prefabricated composite structure system, comprising the steps of:

[0039] S1 lifts and welds the prefabricated L-shaped truss steel columns at the construction site and the embedded parts in the foundation, and relies on its own structure to achieve stability. The structure of the truss columns is as follows: figure 2 As shown, there are several stiffeners 8 in a linear array on the prefabricated steel beam 5, and high-strength bolts 9 are arranged between two adjacent stiffeners 8;

[0040] S2. After all the truss steel columns are hoisted and welded at one time, the prefabricated steel beams 5 and the truss columns are assembled and connected with high-strength bolts 9;

[0041] S3. Prefabricate the floor slab in the factory. The thickness of the prefabricated slab 4 is 80-120mm. When the floor slab is prefabricated, grid steel bars are placed, and 4 bolts, 9 holes and 6 are reserved at both ends of the slab. The structure of the slab is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com