Rapid docking platform and building method thereof

A docking platform and fast technology, applied in the direction of lifting devices, etc., can solve problems such as rigidity and force performance and safety cannot be guaranteed, affect the passage of people or objects, and small particles are easy to fall, so as to achieve convenient deployment and storage, and occupy Small space, effect of reducing welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

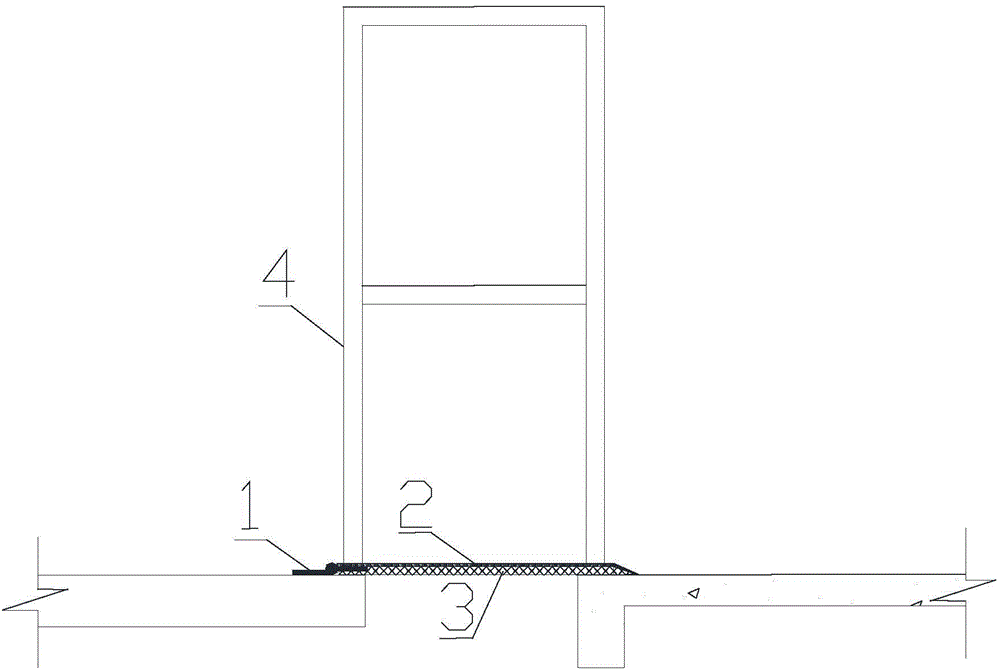

[0022] Such as figure 1 As shown, the rapid docking platform of the present invention is composed of a steel hinge 1, a patterned steel plate 2, a section steel 3, and a protective railing 4. The steel hinge 1 is fixed on the base of the mobile platform, the patterned steel plate 2 is fixed to the steel hinge 1, and the patterned steel plate 2 are respectively welded with section steel 3 and protective railing 4 as a whole.

[0023] The length of the checkered steel plate 2 and the section steel 3 is determined by the gap between the mobile platform and the fixed platform, and the width of the checkered steel plate and the section steel is determined by the size of the mobile platform and the fixed platform.

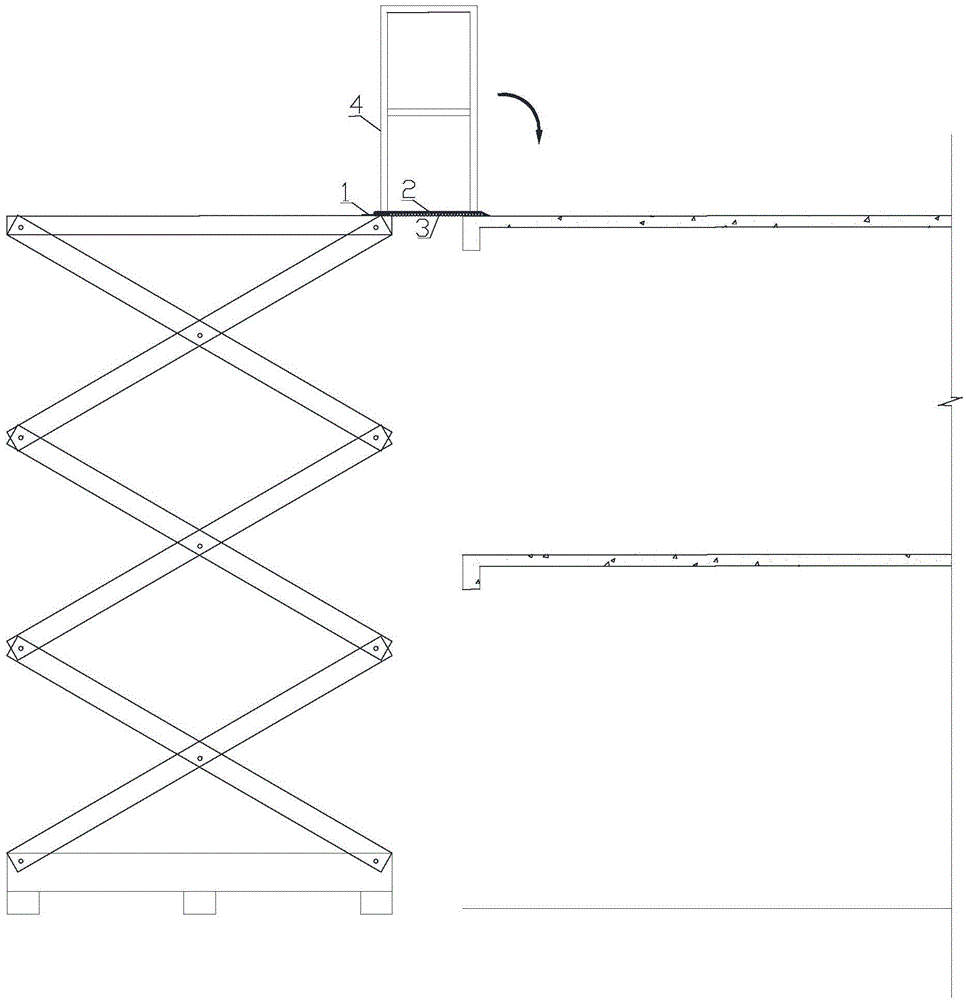

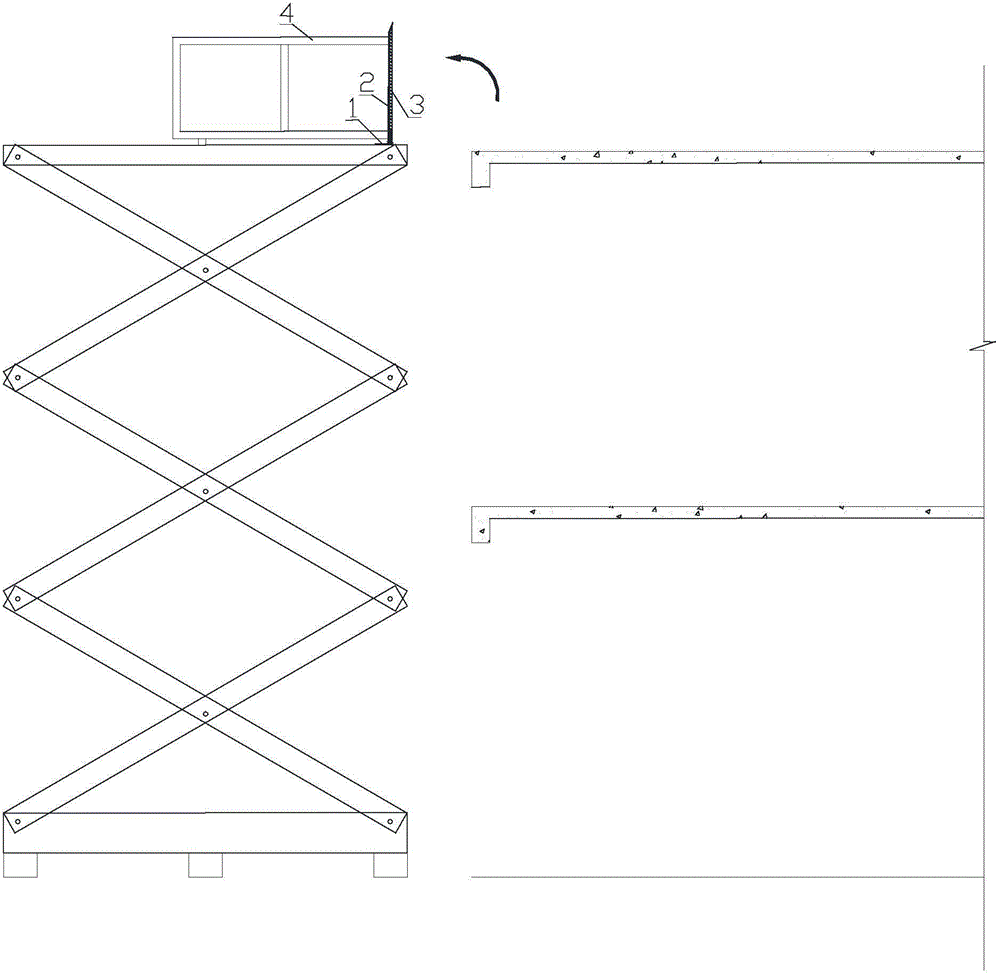

[0024] Such as figure 2 As shown, through the lifting movement of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com