Power transmission tower and power transmission tower supporting pillar

A technology for supporting columns and transmission towers, applied in towers, buildings, building types, etc., can solve problems such as large loads and excessive diameter-to-thickness ratio of large-diameter steel tubes, achieve high pressure bearing capacity, and increase the ratio of tube diameter-to-thickness. Limits, the effect of reducing the amount of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

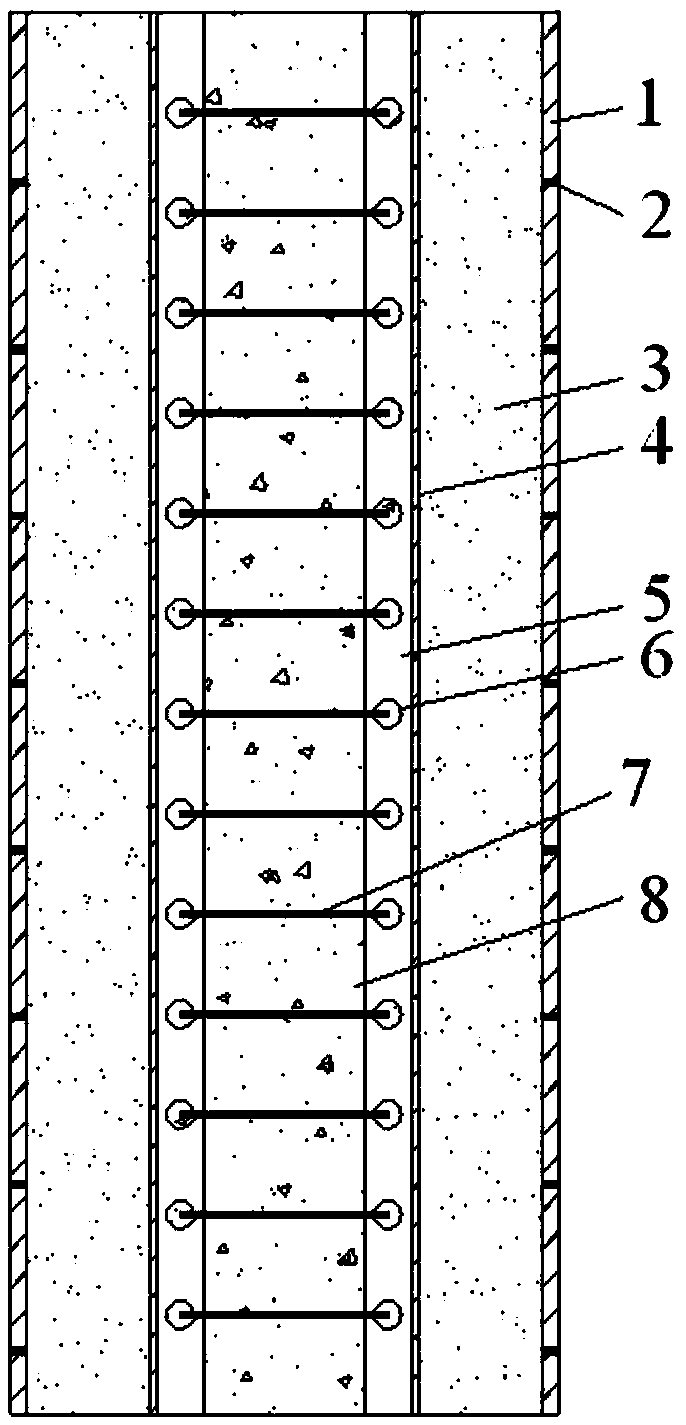

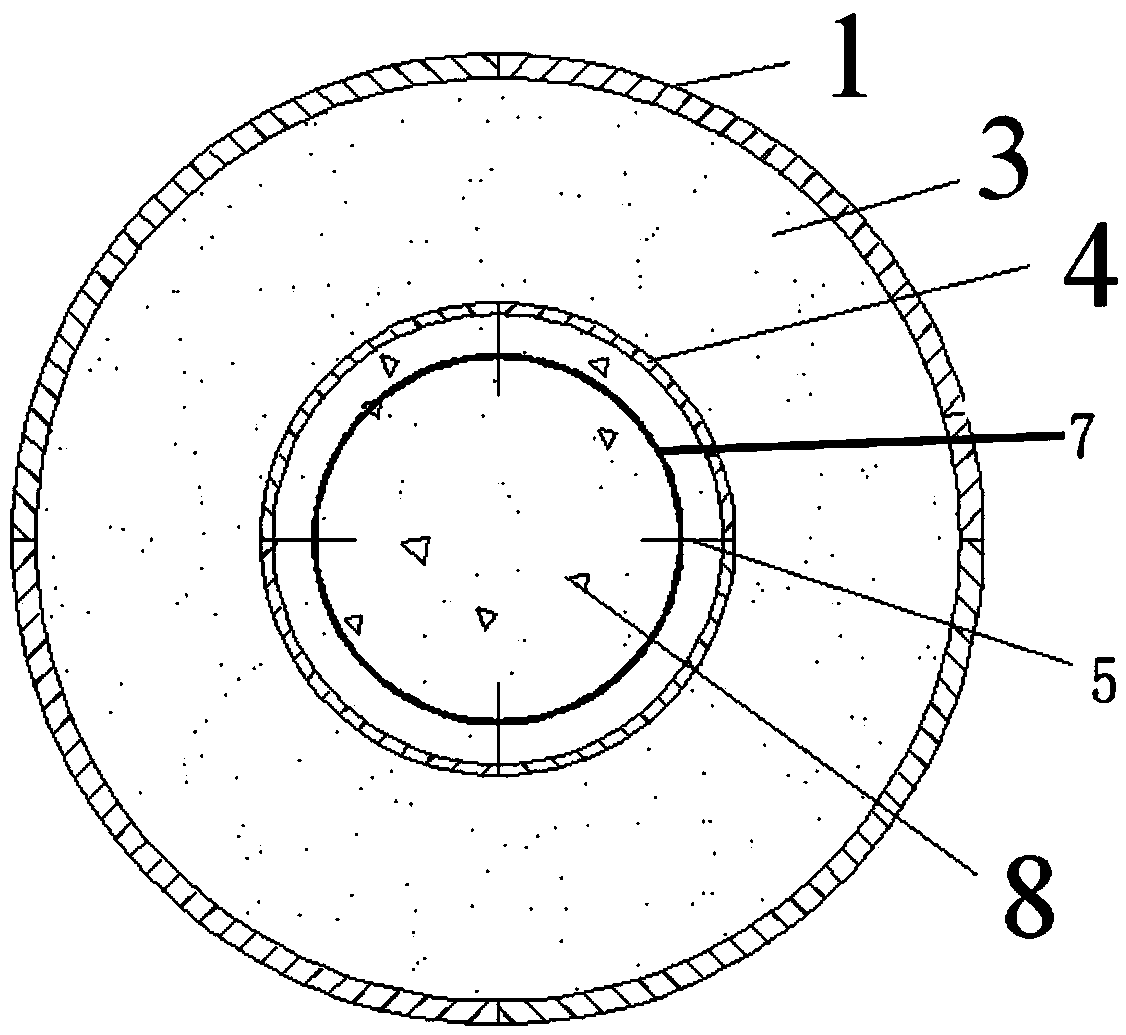

[0028] Such as Figure 1 to Figure 3 As shown, the present invention provides a support column for a transmission tower, the transmission tower includes: a vertically arranged tower body and a cross arm arranged horizontally on the top of the tower body, and a support column is longitudinally provided at the bottom of the tower body; The support column includes: an adhesive 8, a reinforcing frame and an outer tube 1 arranged radially from the inside to the outside; a mortar 3 is arranged between the outer wall of the reinforcing frame and the inner wall of the outer tube;

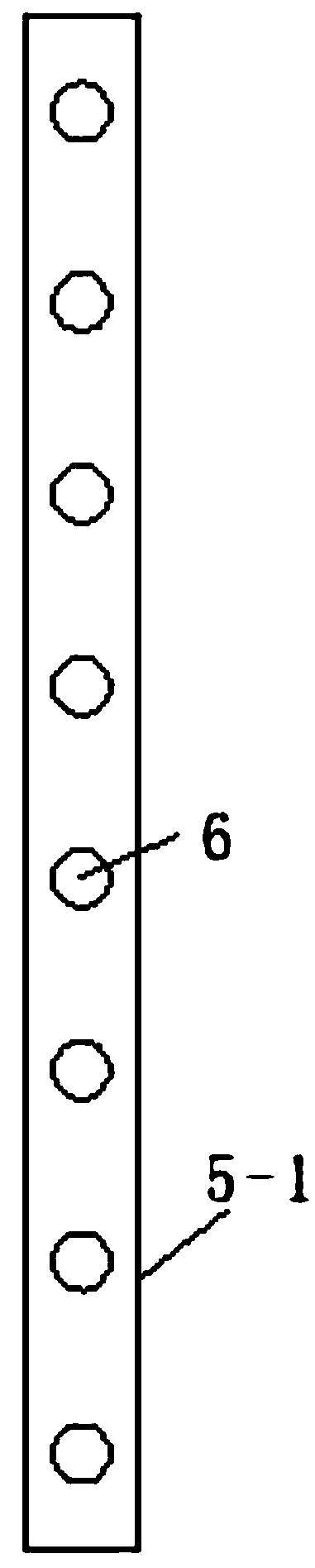

[0029] The reinforcing frame includes: the inner layer tube 4, the stiffening rib 5 and the cage rib 7 are sequentially arranged radially from the outside to the inside;

[0030] The stiffeners include: a reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com