Heat exchange coil pipe, heat exchange coil pipe group and evaporative condenser

An evaporative condenser and heat exchange coil technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of different cleanliness and hardness of cooling water, influence of unit use effect, etc. Achieve the effect of preventing scale from depositing on the surface of the heat exchange tube, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

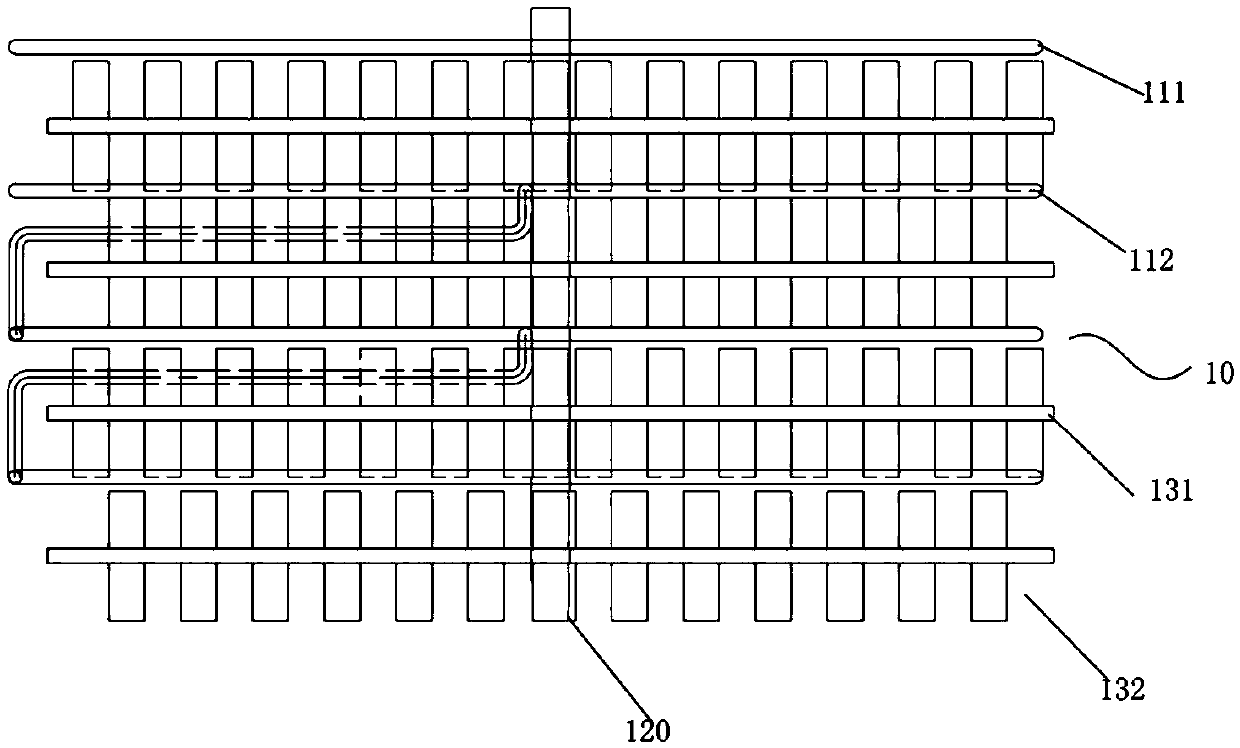

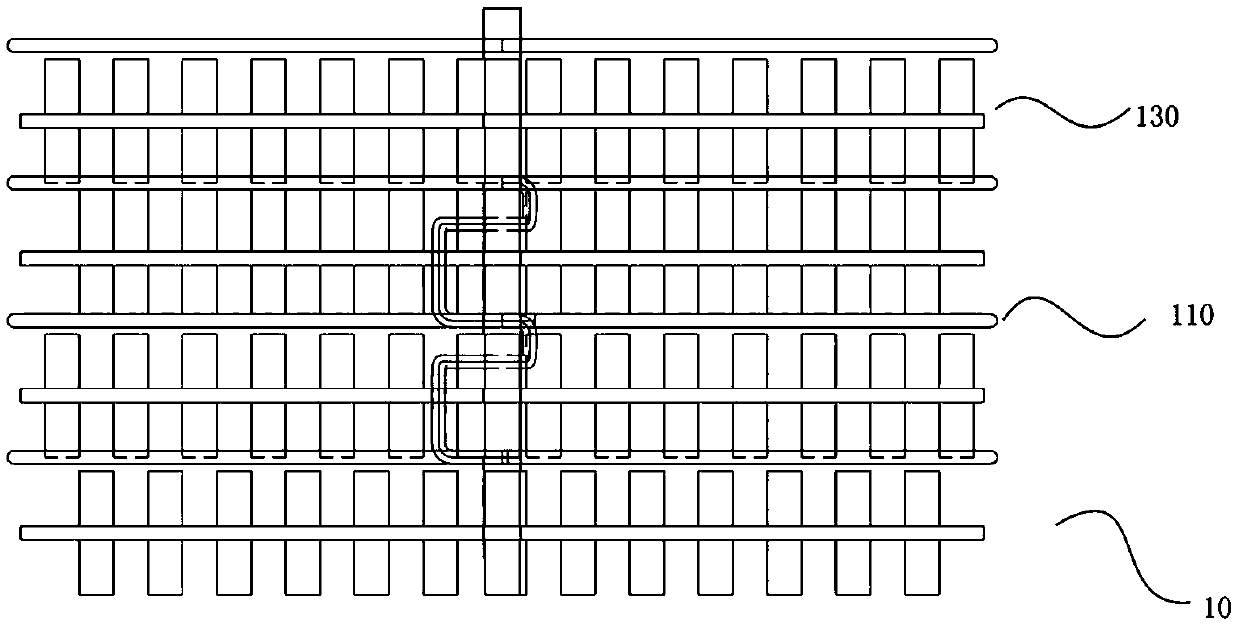

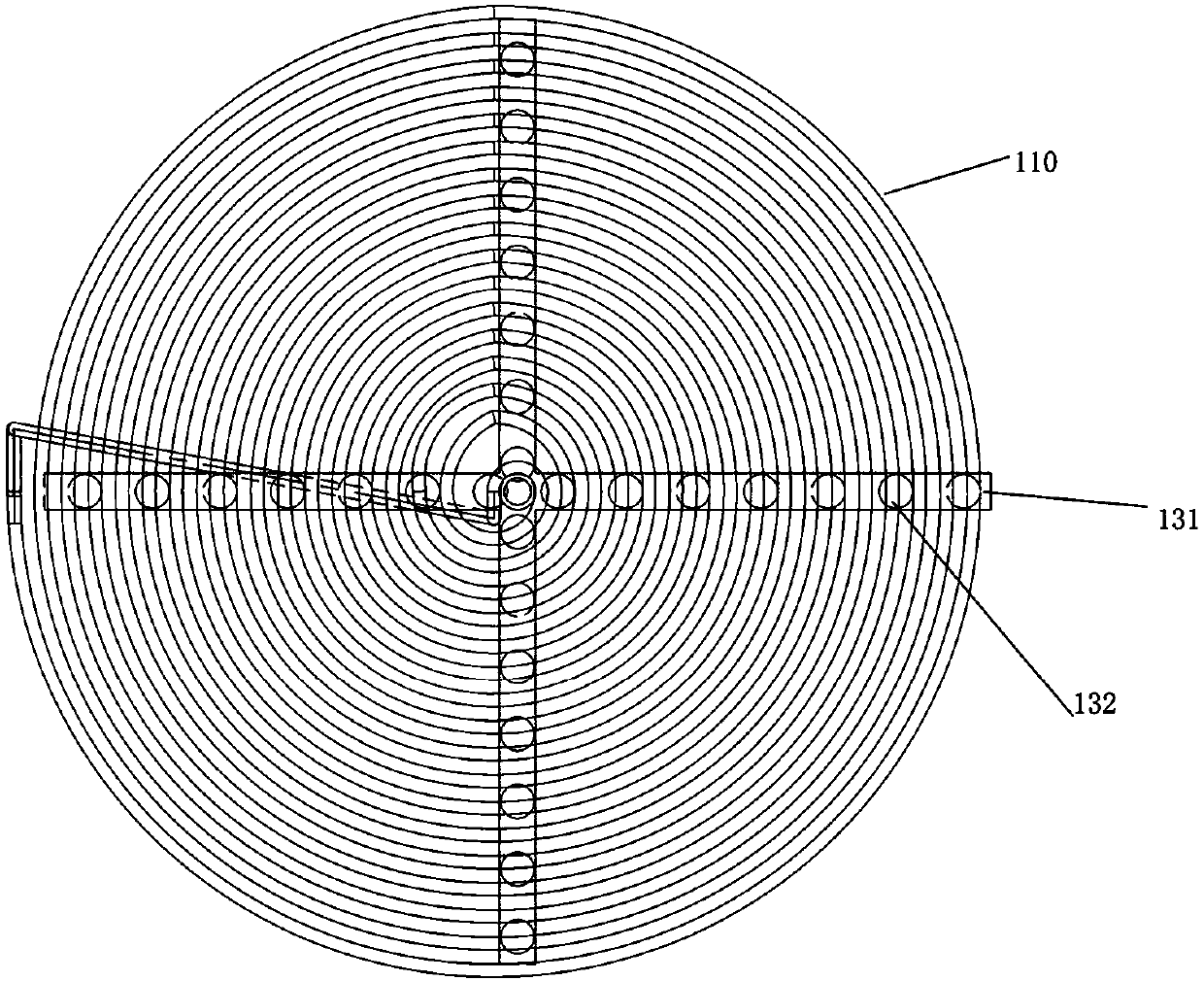

[0022] Embodiment 1: as Figure 1-4 As shown, a heat exchange coil 10 according to the present invention includes several vortex heat exchange coils 110 connected in series, and a rotating shaft 120 made of stainless steel passing through the centers of several vortex heat exchange coils. , a cleaning device 130 connected to the rotating shaft between adjacent heat exchange coils.

[0023] The vortex-shaped heat exchange coil 110 is wound from a metal tube. The vortex-shaped heat-exchange coil 110 is arranged in layers along the direction in which the central axis of the heat-exchange coil extends. Two series-connected vortex-shaped heat-exchange coils 110 is a repeating unit. For the convenience of description, the upper layer of the repeating unit is the first scroll heat exchange coil 111, the lower layer is the second scroll heat exchange coil 112, and the first scroll heat exchange coil The outlet of the tube is connected with the inlet of the second vortex heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com