Sea bond structure for FPSOsuperstructure total segment during lightering

A superstructure and barge technology, which is applied in the directions of superstructure, ship construction, transportation and packaging, can solve the problems of the special tire frame being difficult to use repeatedly, the tire frame production is difficult, and the welding workload is large, so as to meet the transportation safety requirements. performance, reduce labor costs and time costs, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

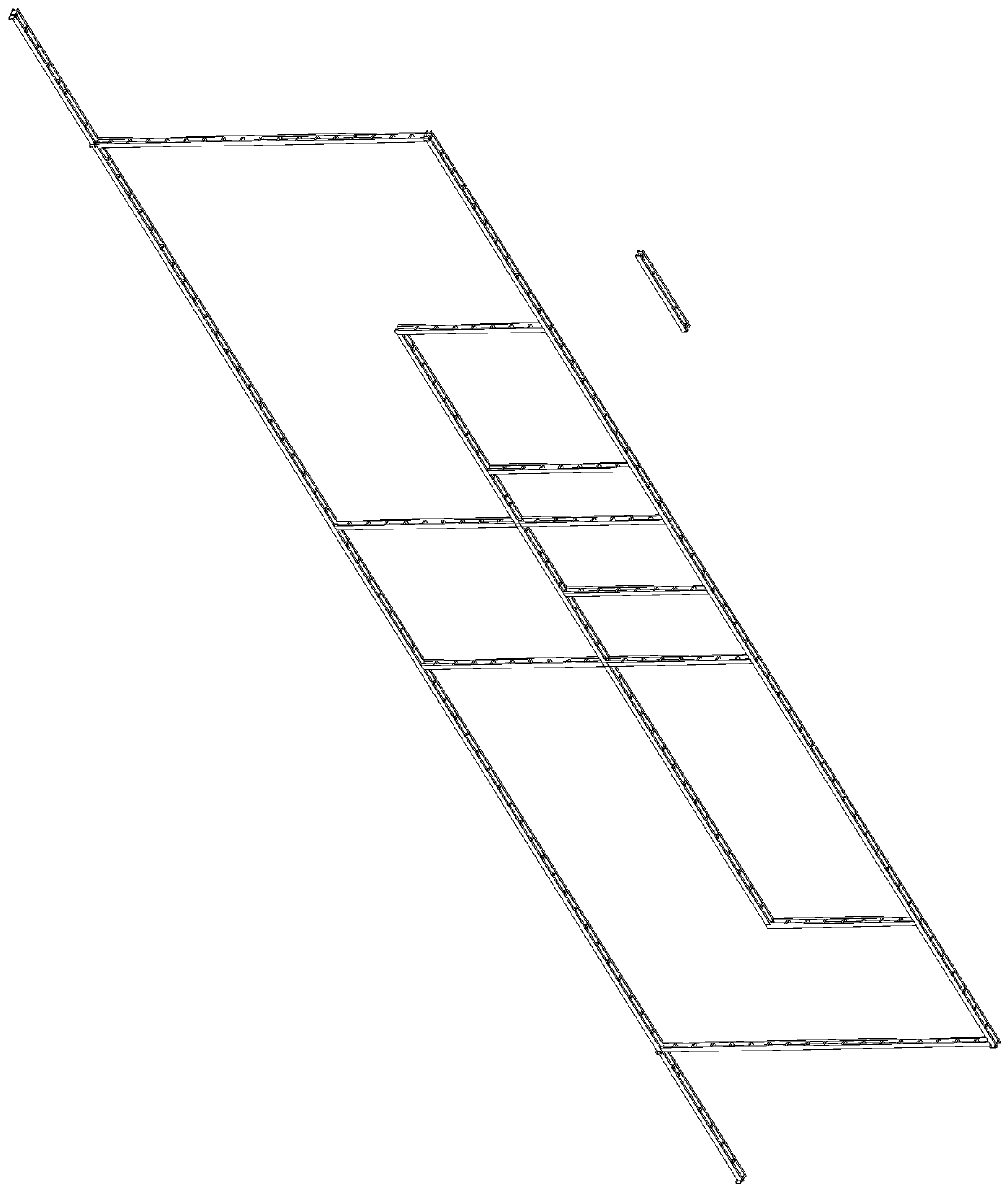

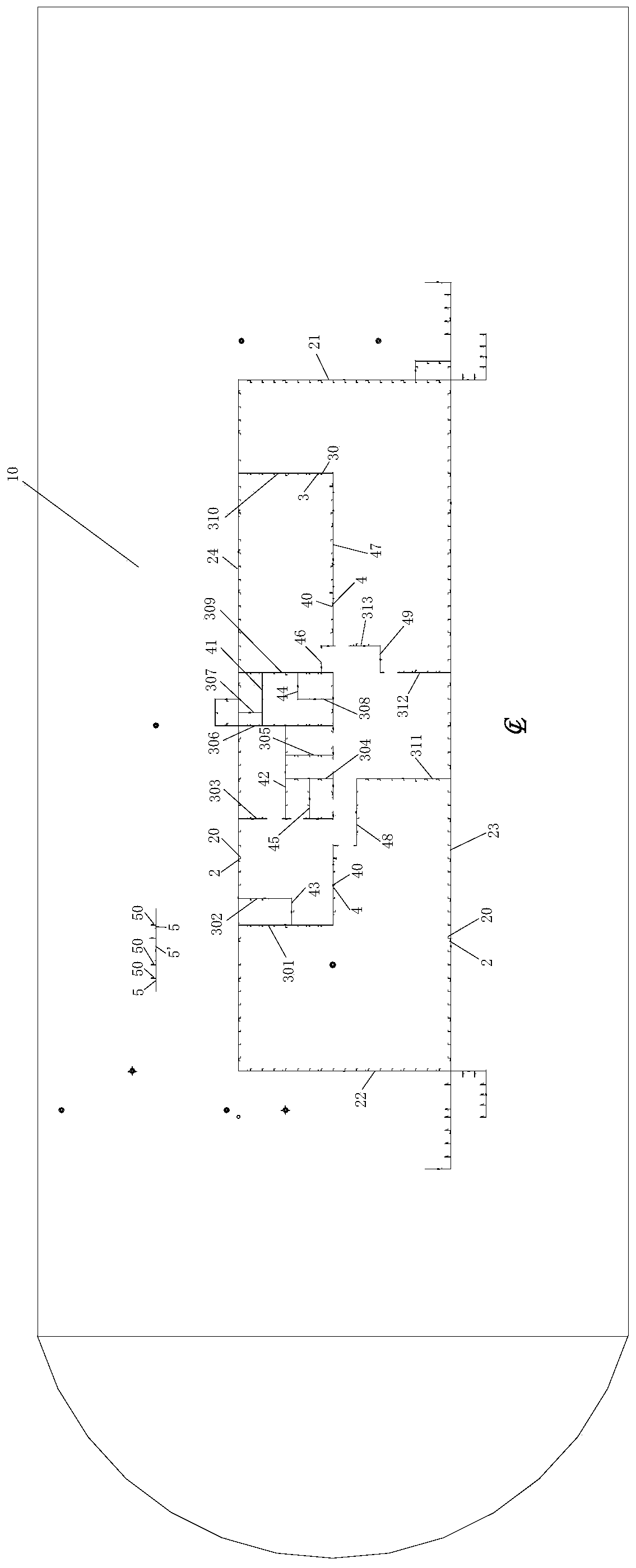

[0026] see Figure 1 to Figure 8 , a sea-state structure for lightening the general superstructure section of an FPSO according to the present invention, comprising a barge 10, a general superstructure section, a plurality of surrounding wall sea ties 2, a plurality of longitudinal sea ties 3, and a plurality of transverse sea ties 4 And two outer wall sea bindings 5.

[0027] The general section of the superstructure comprises rectangular enclosure walls, inner walls and outer walls 5'.

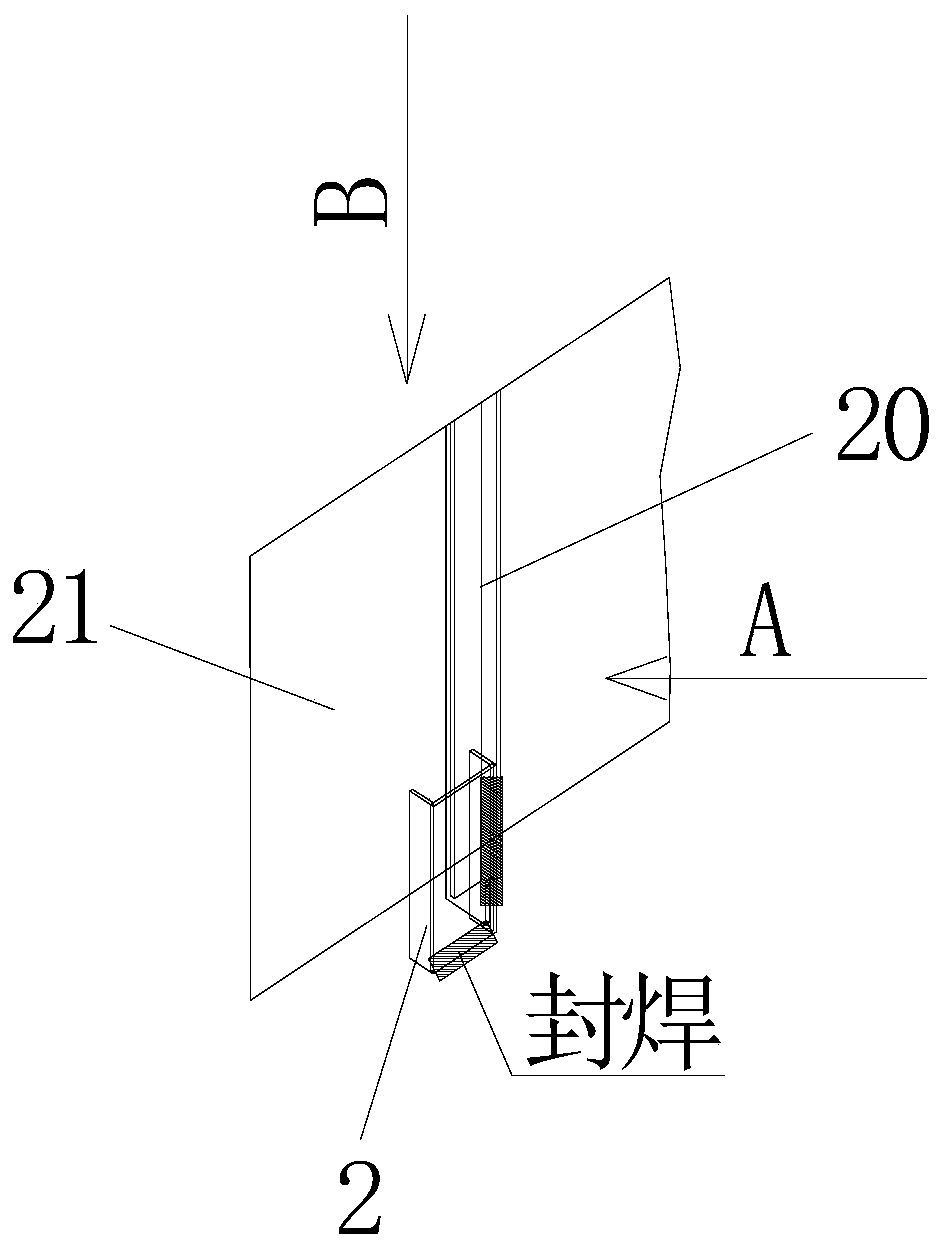

[0028] The bulkhead comprises a port bulkhead 21, a starboard bulkhead 22, a bow bulkhead 23 and a stern bulkhead 24; The surrounding wall vertical stiffeners 20 whose lower ends protrude from the lower ends of all the surrounding walls by 88 mm are evenly spaced.

[0029] The inner wall is arranged in the surrounding wall and includes first to thirteenth longitudinal inner walls 301-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com