Ultrasonic sensor device

A sensor device, ultrasonic technology, applied in the field of sensors, can solve problems such as increased manufacturing costs, signal attenuation, and difficulty in welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

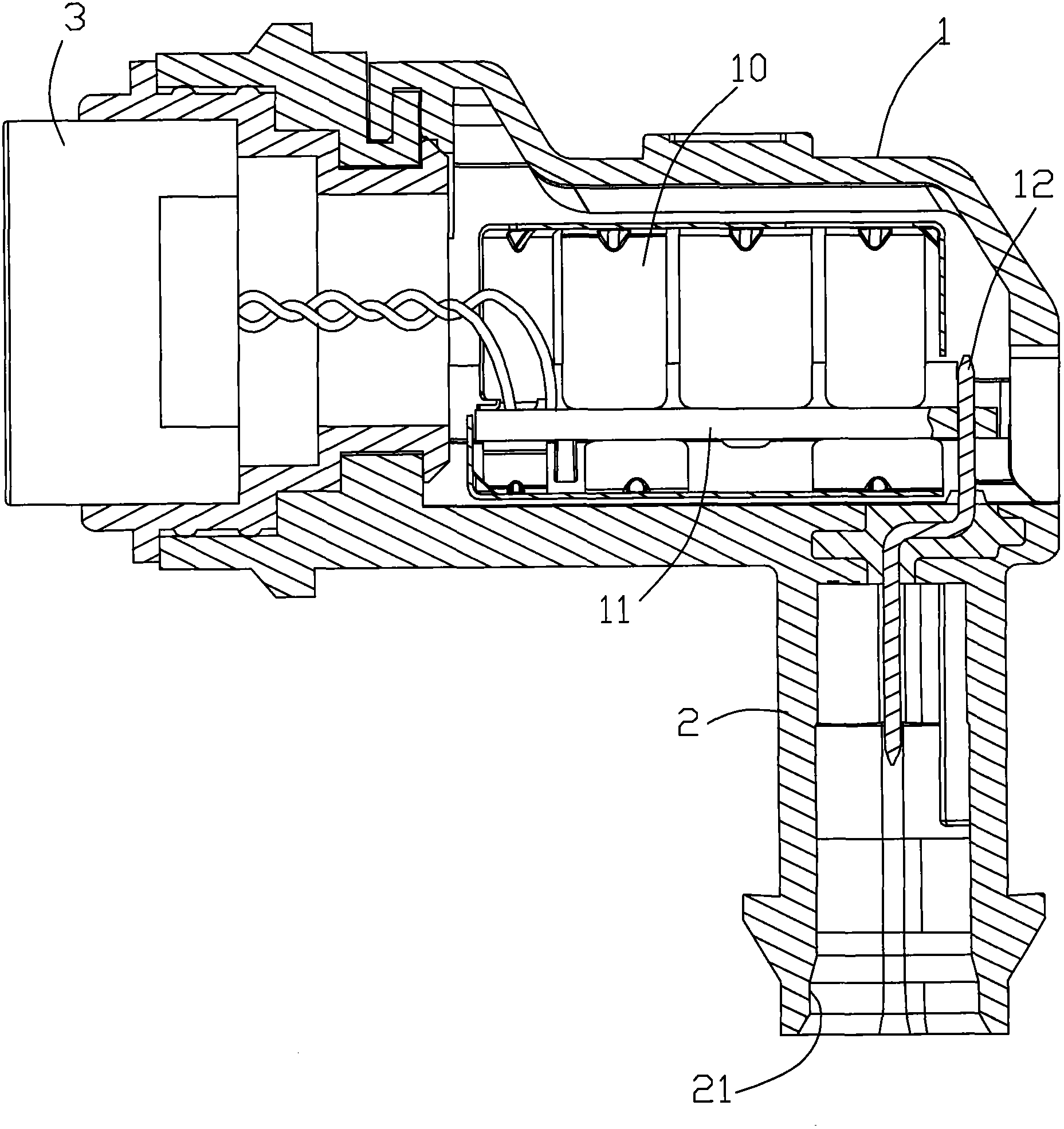

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

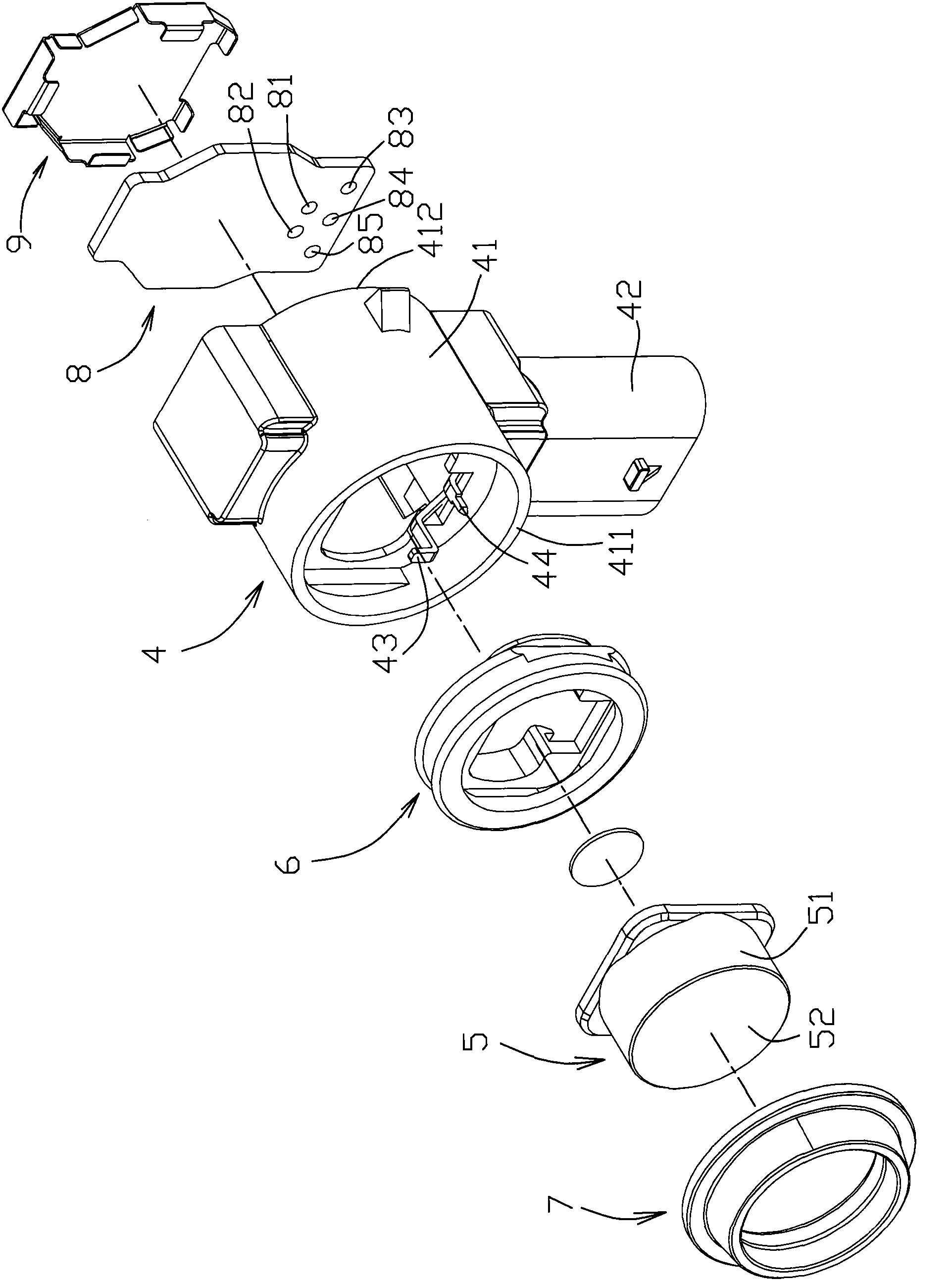

[0023] see Figure 3 to Figure 5 As shown, a preferred embodiment of the ultrasonic sensor device of the present invention includes a housing 4 , a transducer (transducer) 5 , an annular seat 6 , an O-ring 7 , a circuit board 8 and an isolation cover 9 .

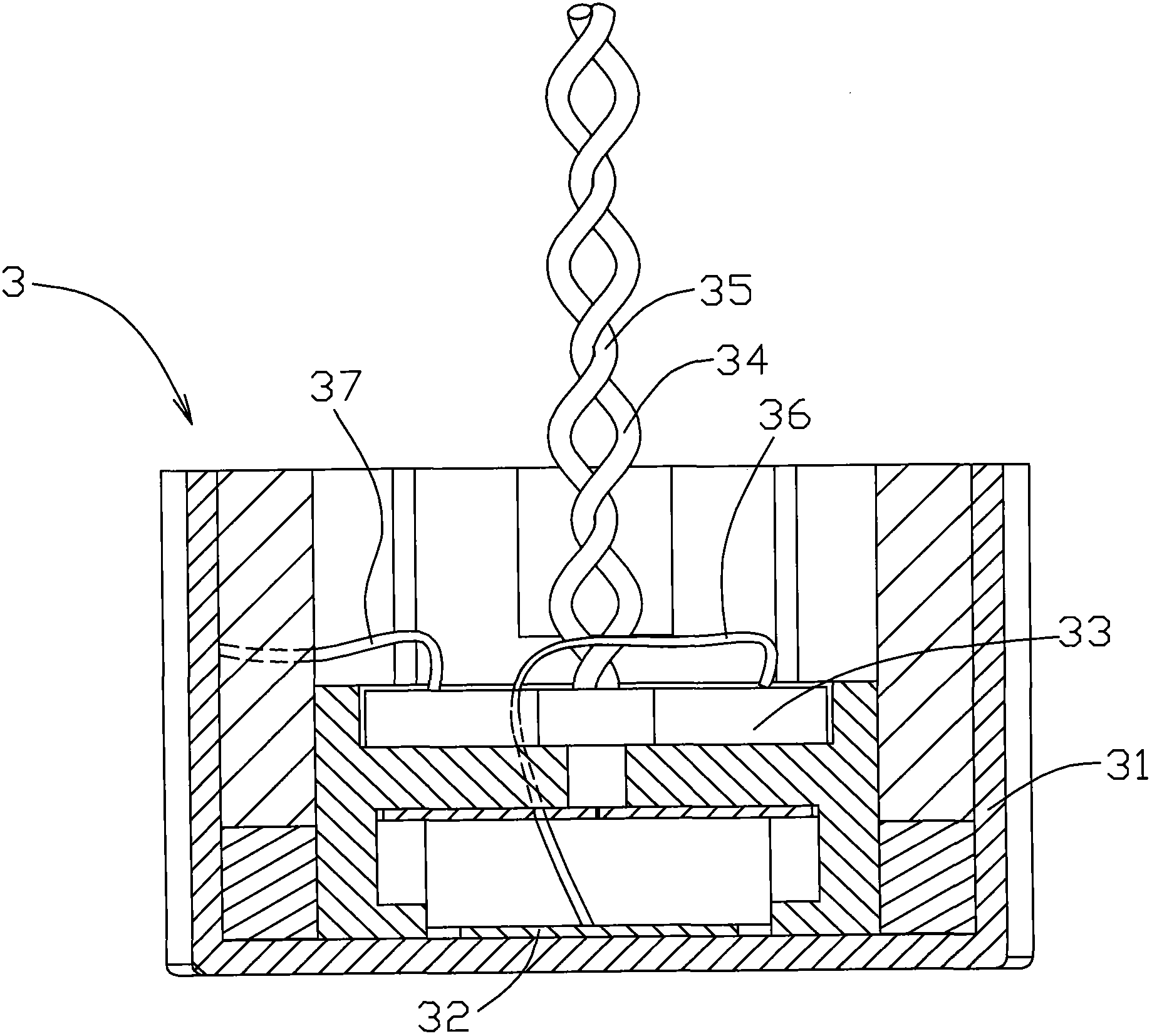

[0024] The shell 4 includes a hollow shell 41, a connecting pipe portion 42 and five connecting pins 43-47. The hollow shell 41 is formed by an annular surrounding wall 48 and has a first opening which is opposite and communicated with each other. 411 and a second opening 412 . One end of the connecting pipe portion 42 is connected to the surrounding wall 48 of the hollow shell 41, and the other end has a third opening 421, and in this embodiment, the connecting pipe portion 42 and the hollow shell 41 are integrally formed, but This is not the limit. These pins 43-47 are fixed in the hollow housing 41, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com