Hanging ladder type scaffold for mounting water-cooled wall spiral section and its erection method

A technology of water-cooled wall and spiral section, which is applied to the scaffolding of building structure support, building structure support, building structure support, etc., which can solve the problems of increasing the quality risk of cutting damaged pipes, occupying scaffolding materials, and damaging pipes, etc., so as to reduce the long time The risk of high-altitude safe operation, the reduction of cutting and grinding or welding work, and the effect of reducing personnel input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment:

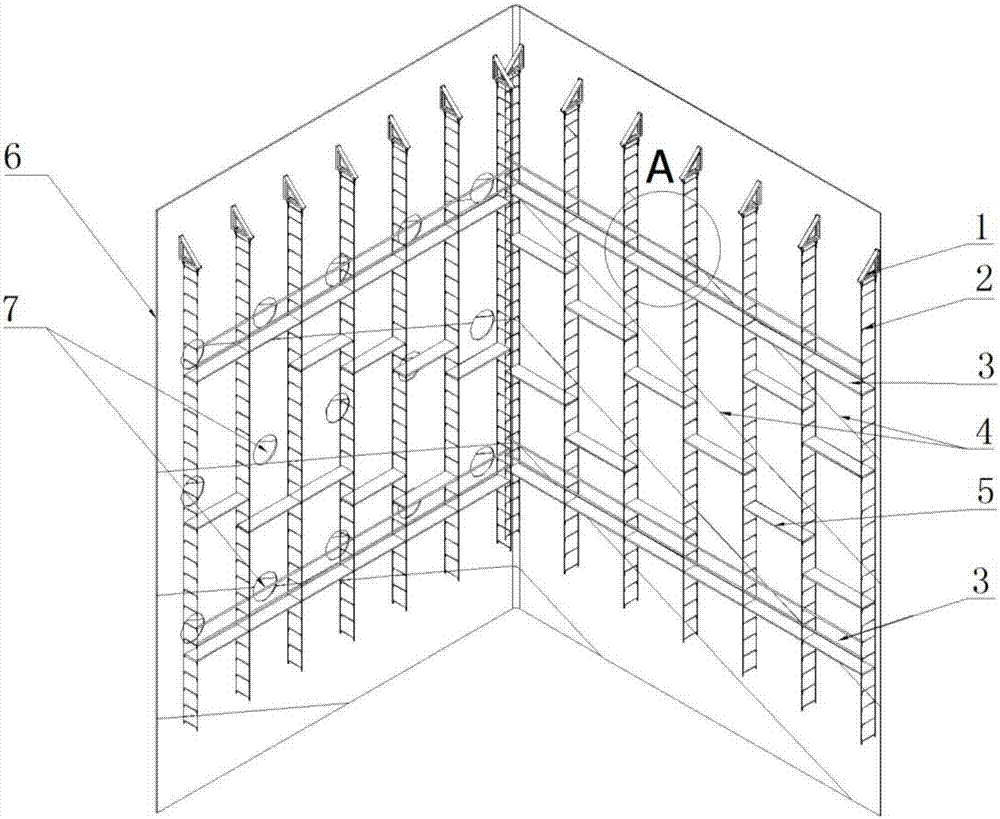

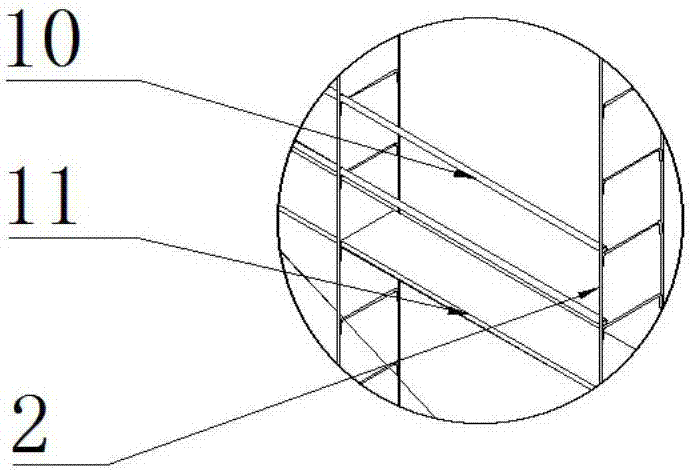

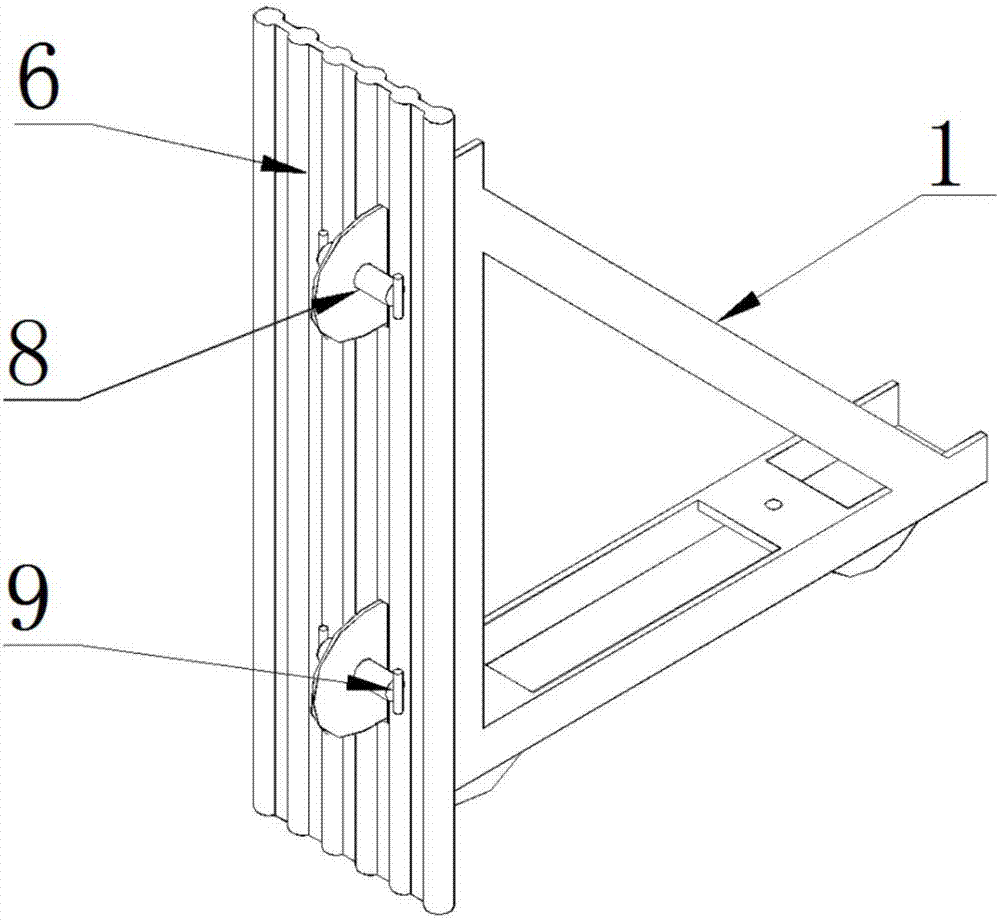

[0025] The suspended ladder scaffolding used for the installation of the spiral section of the water-cooled wall includes several load-bearing supports 1 and annular passages 3. It is characterized in that the load-bearing supports 1 pass through the fins of the external water-cooled wall 6 and are fixed by round steel 8. Both ends of the round steel 8 are welded with non-slip iron parts 9, and a ladder 2 is correspondingly hung below each of the load-bearing supports 1, and the ladder 2 is connected by several ladder hooks. The water-cooled wall 6 is hung relatively parallel, and a construction area 5 is provided around the weld 4 on the water-cooled wall 6. The construction area 5 includes a protective railing 10 and several scaffolding boards 11, and the scaffolding board 11 is located on the ladder 2 and along the welding seam 4 in a stepped manner, the protective railing 10 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com