A waterway welded stuffing box

A stuffing box and welding technology, which is applied in the field of stuffing box, can solve the problems of difficult disassembly and maintenance, and achieve the effect of reducing grinding work, convenient maintenance and disassembly, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

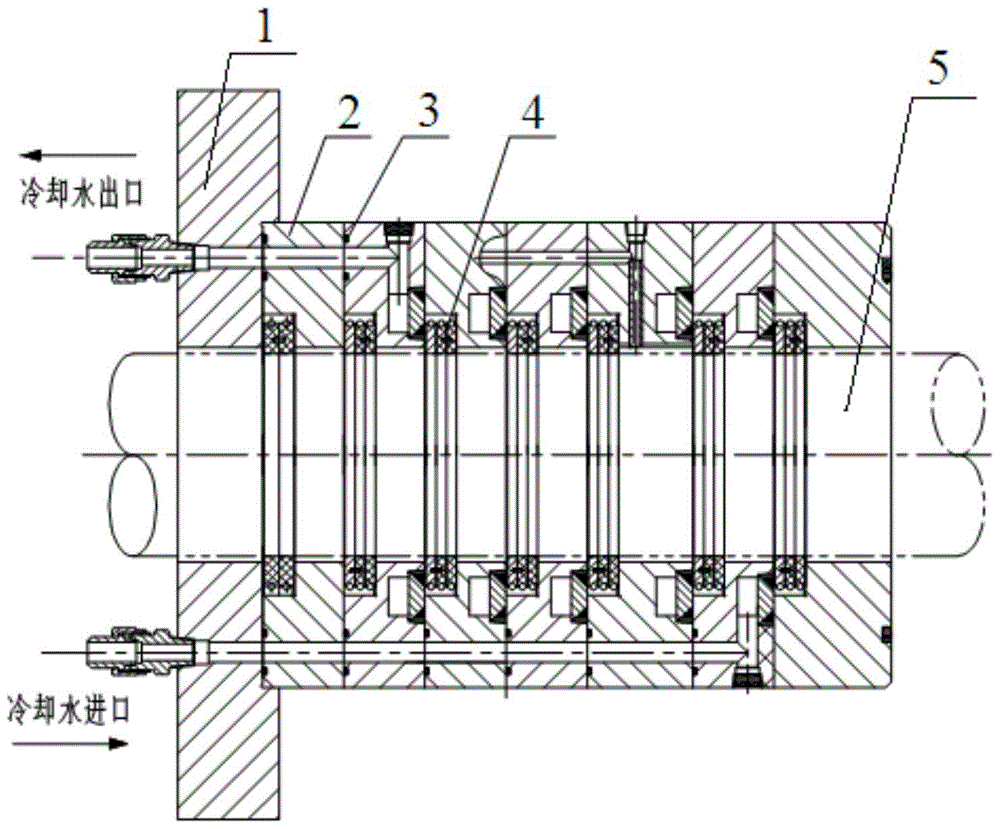

[0027] A channel welded stuffing box, such as figure 1 As shown, the stuffing box is set between two flanges 1 on the piston rod 5, and the stuffing box includes stuffing boxes 2 closely arranged, and stuffing rings 4 arranged between adjacent stuffing boxes 2; among them, the stuffing ring 4 uses 3 petals With spring tension structure.

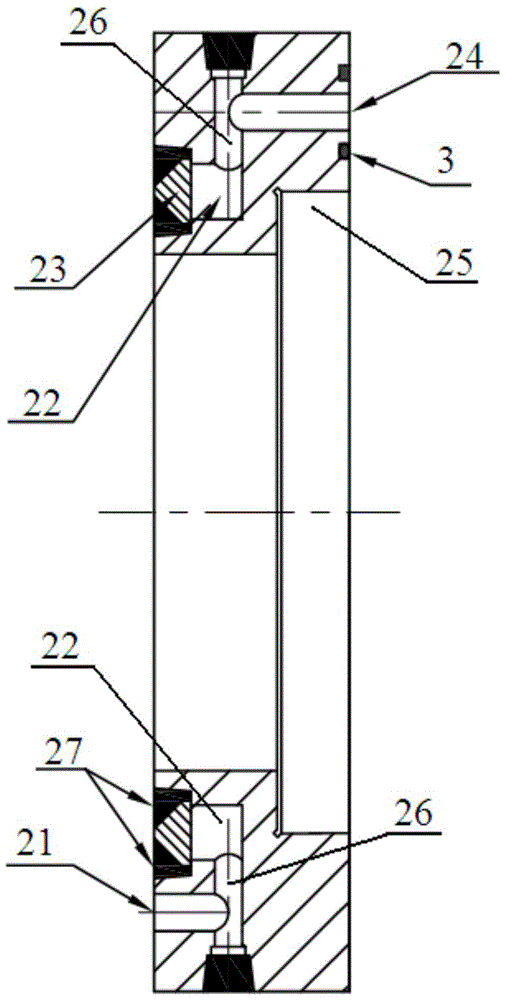

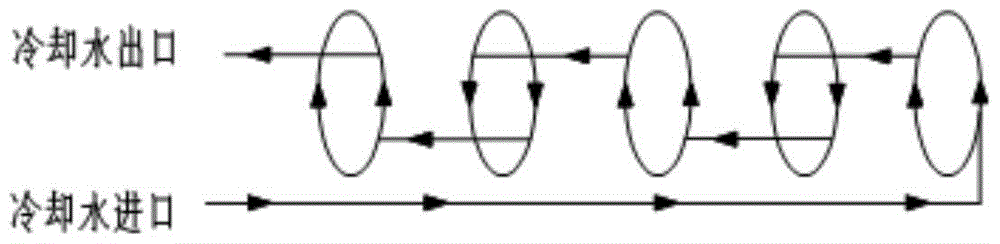

[0028] refer to figure 2 , the stuffing box 2 is a hollow disc-shaped body, wherein an annular water tank is provided on one side of the stuffing box 2, a partition 23 is arranged at the opening of the annular water tank, and the partition 23 is welded and sealed with the opening of the annular water tank to form a closed Weld seam 27, so that the inside of the annular water tank forms a closed annular water channel 22, and the left and right sides of the stuffing box 2 are respectively provided with an inlet water channel 21 and an outlet water channel 24 that communicate with the annular water channel 22, and two adjacent stuffing boxes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com