Roller Cam Followers

A technology of roller cams and moving parts, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as consumption, and achieve the effect of reducing grinding work, economical manufacturing, and fast passing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

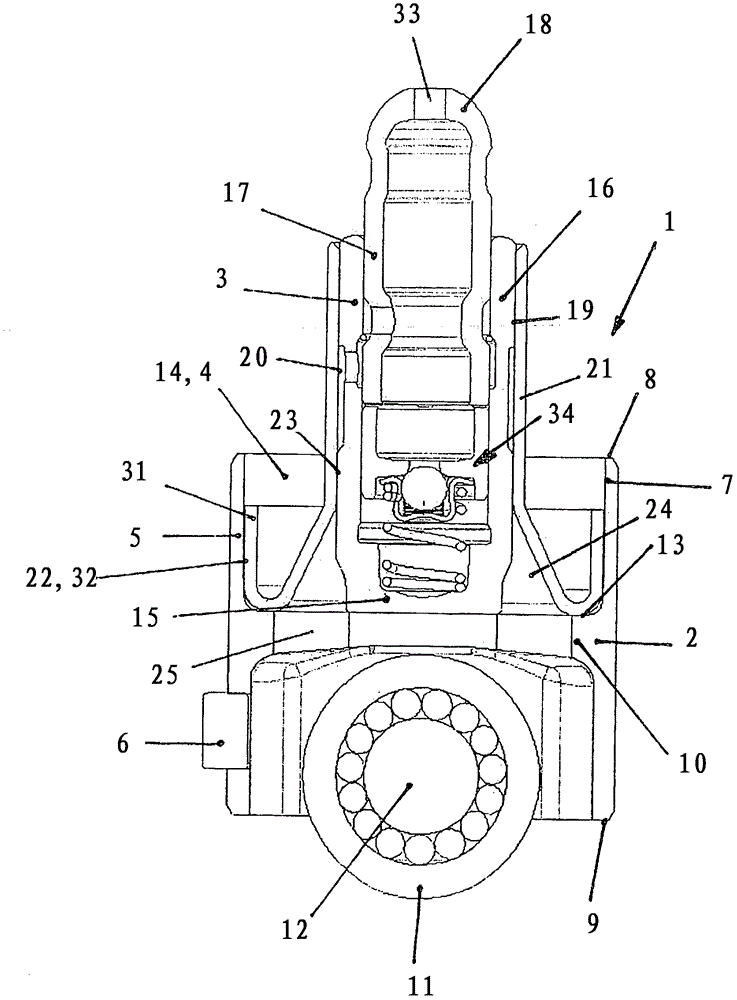

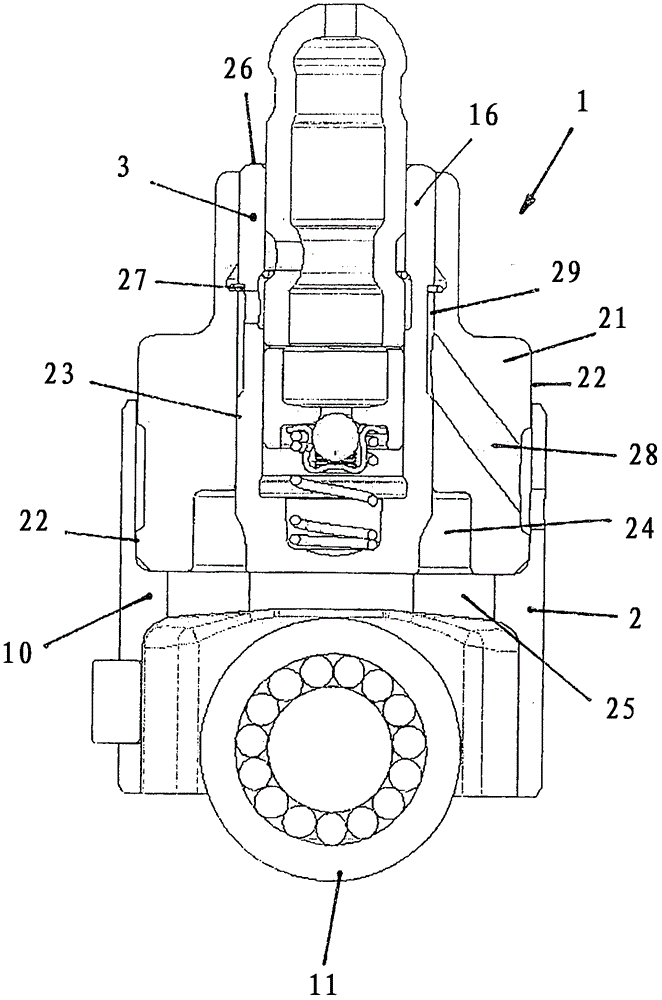

[0017] The figure shows a roller cam follower 1 . The roller cam follower is used to reciprocate the rocker arm in an overhead valve train with an underlying camshaft. The roller cam follower consists of a roller tappet 2 , which actuates a piston of a high-pressure fuel pump to and fro, and a hydraulic bearing element 3 . Here the bearing element 3 rests in the recess 4 of the roller tappet 2 formed by the upper side 13 of the bridge section 10 and the inner peripheral surface 7 of the housing 5 . The adapter ring 21 serves as a connecting element.

[0018] The roller tappet 2 has a cylindrical housing 5 with a protruding anti-rotation fastening 6 , which here is present as a pin. The inner peripheral surface 7 of the housing is spaced apart from the edges 8, 9 of the housing 5, approximately at half the height, and is spanned by a bridge section 10, below which a cam roller 11 is arranged, so that The cam rollers are supported on pins 12 mounted in the housing 5 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com