Patents

Literature

32results about How to "Short passage time" patented technology

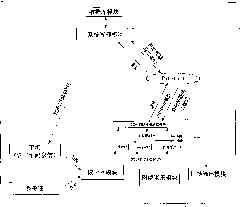

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triple-authentication gate control system and control method

InactiveCN101826227AReduce data trafficReduce communication costsTelevision system detailsCharacter and pattern recognitionSystems managementComputer module

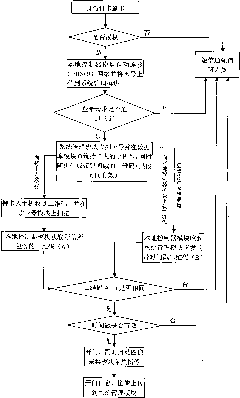

The invention discloses a triple-authentication gate control system and a control method. The triple-authentication gate control system comprises an image collection module, a card reader module, a local controller module, a gate control output module, a mobile phone, a system management module and a database module. Through verifying whether an identity card is legal or not, the local controller module is triggered to be connected to Internet through 3G / GPRS, the system management module receives the login request of the local controller to generate random two-dimensional codes and time stamps which are sent into the mobile phone and the local controller module through multimedia messages and network, then, the local controller obtains two-dimensional codes through the card reader module, and compares the obtained two-dimensional codes to the two-dimensional codes downloaded from the system management module through 3G / GPRS network, next, the time stamp comparison is carried out, finally, whether all the authentication is legal or not is judged, and the gate is opened and images are collected if all the authentication is legal. The invention ensures high safety of the gate control system, has the advantages of short authentication time, high authentication accurate rate and low cost, and is favorable for large-range application and popularization.

Owner:GUANGZHOU HORIZONTAL INFORMATION TECH

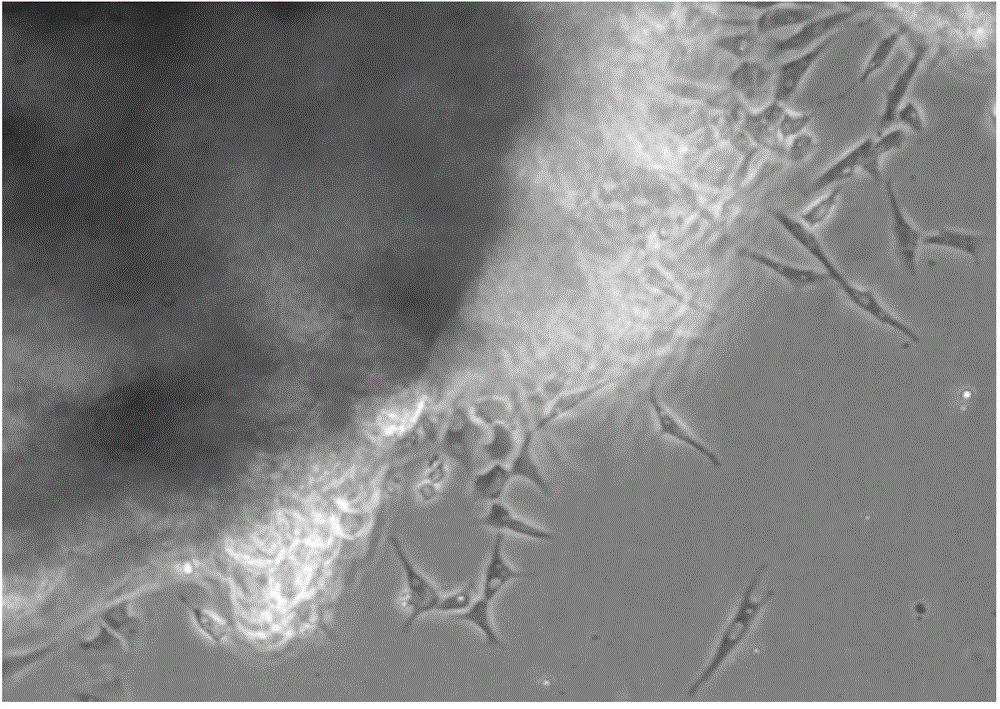

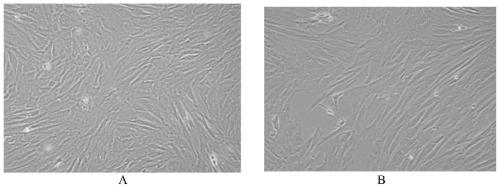

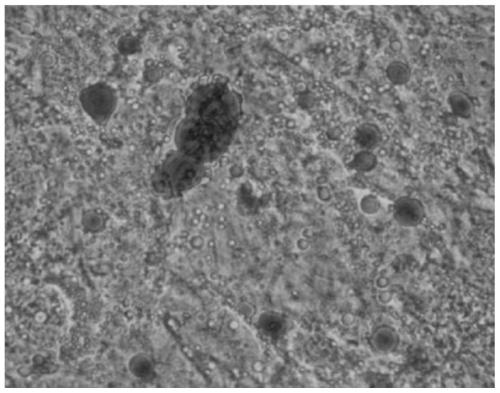

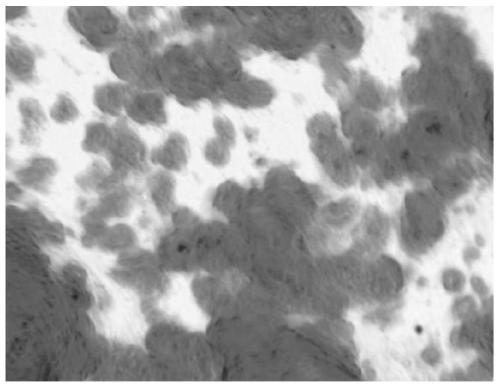

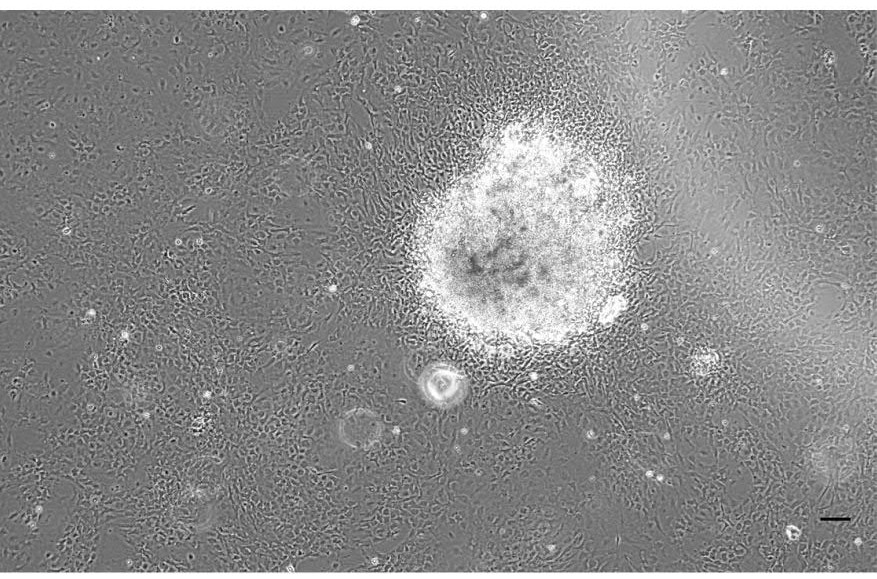

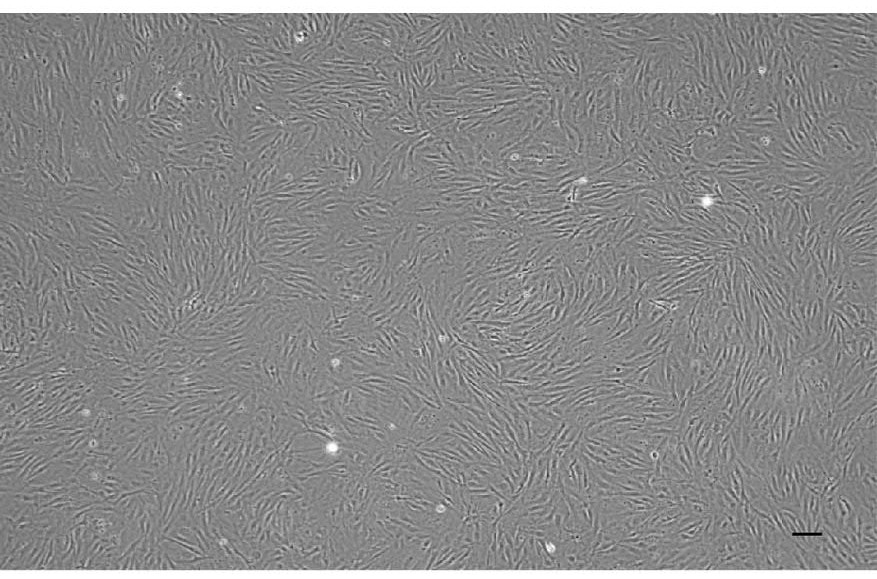

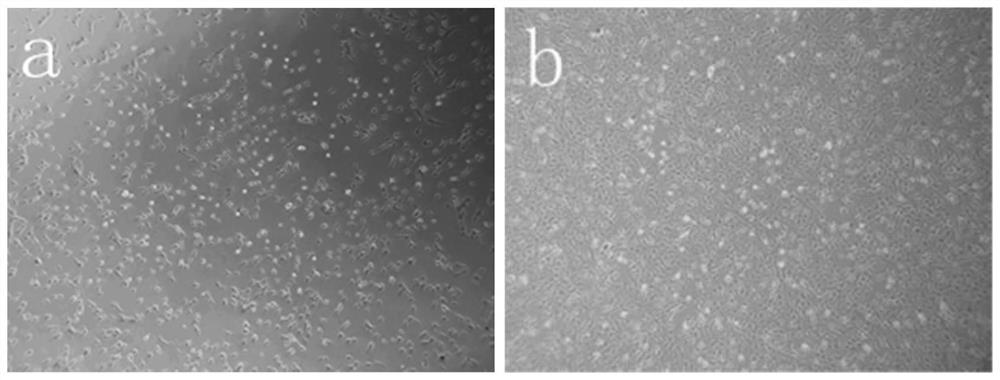

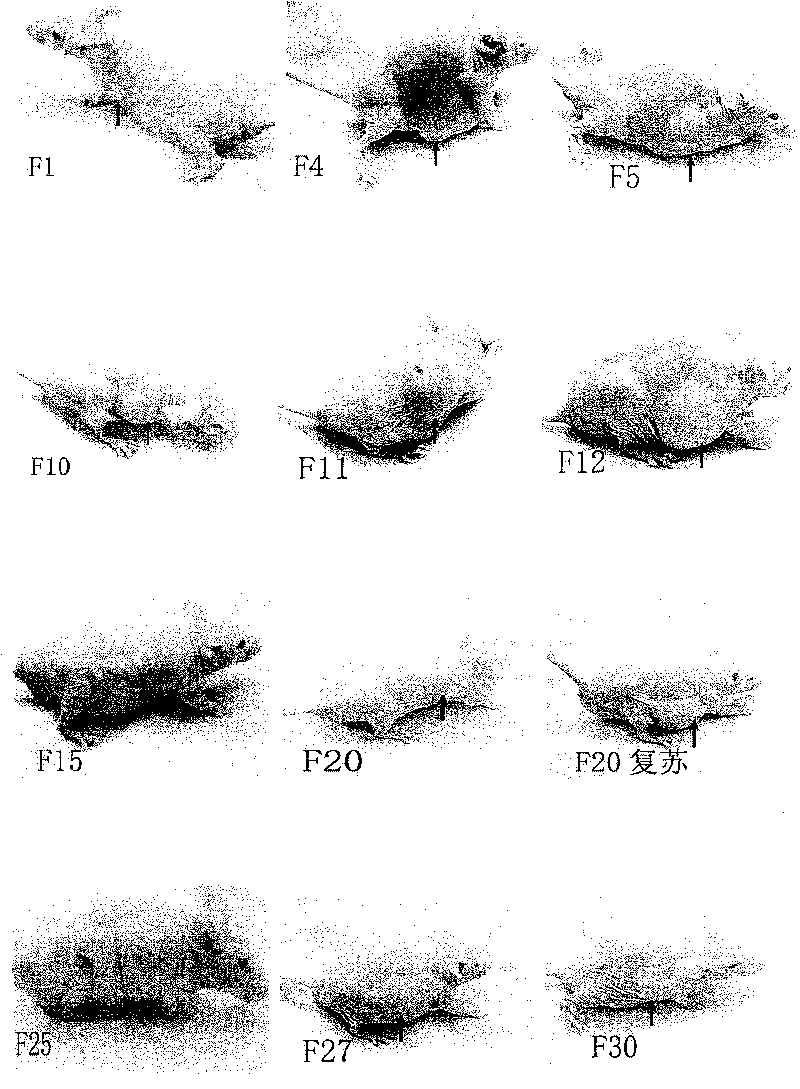

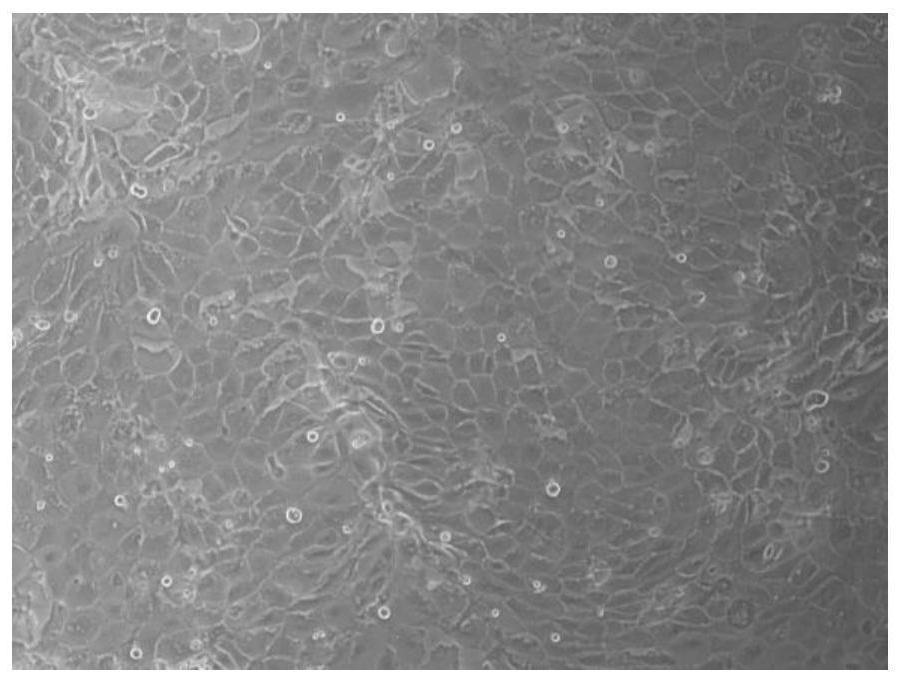

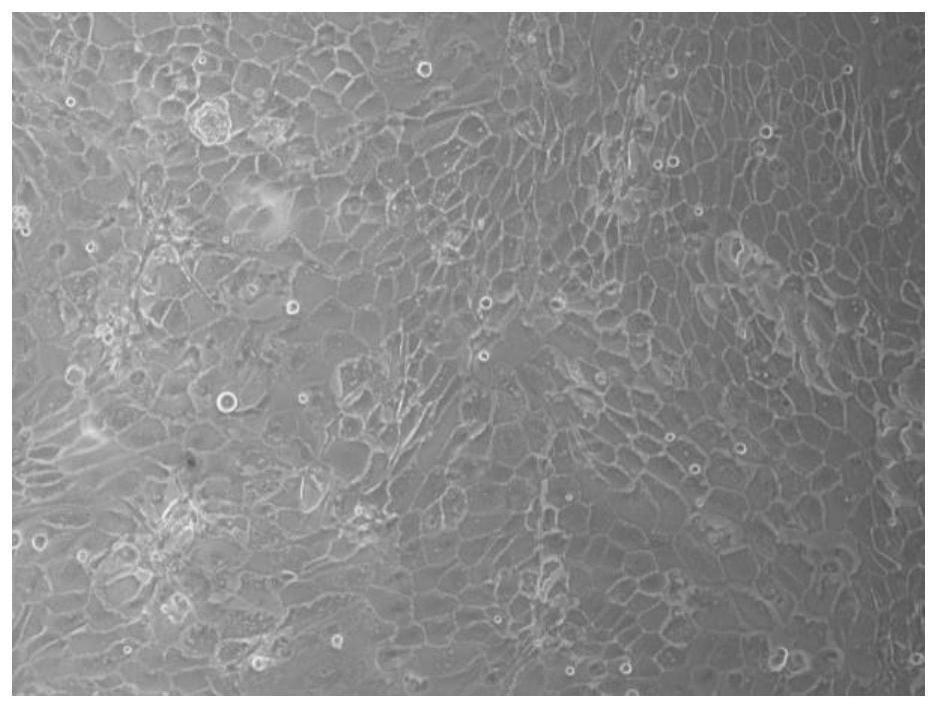

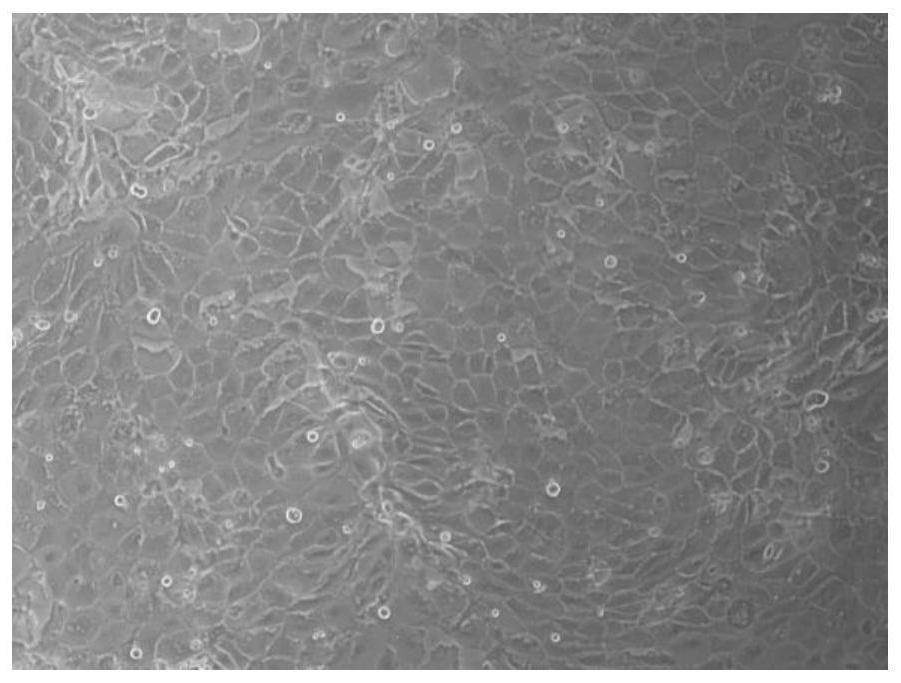

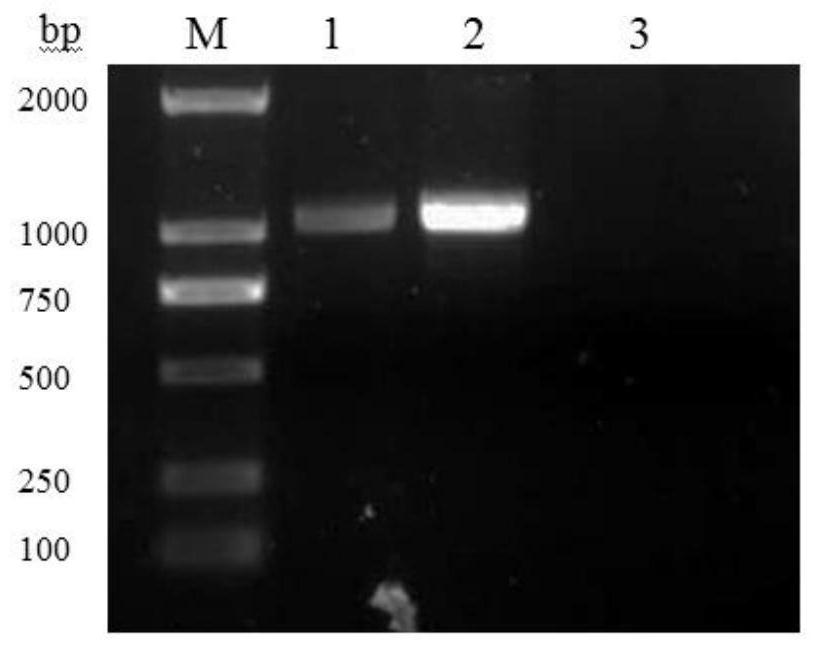

Larimichthys crocea liver cell line and establishment method thereof

InactiveCN103992981AImprove stabilityGood repeatabilityMicroorganism based processesVertebrate cellsSerial passageDigestion

The invention discloses a larimichthys crocea liver cell line and an establishment method thereof. The larimichthys crocea liver cell line is preserved in the China center for type culture collection (CCTCC) On October 31, 2013 and has a preservation number of CCTCC NO: C2013157. The larimichthys crocea liver cell line can realize serial passage, can provide a large amount of larimichthys crocea liver cell lines, can be used for pathogenic characteristic research, vaccine development, functional gene research and breeding research, has excellent properties, comprises fibroblast-like cells and mainly comprises cells having parapodiums stretching out and irregular shapes. The larimichthys crocea liver cell line has the advantages of exuberant division, short passage time, easy digestion, good adherence rate and hunger resistance. The establishment method has good repeatability. The larimichthys crocea liver cell line has good stability.

Owner:JIMEI UNIV

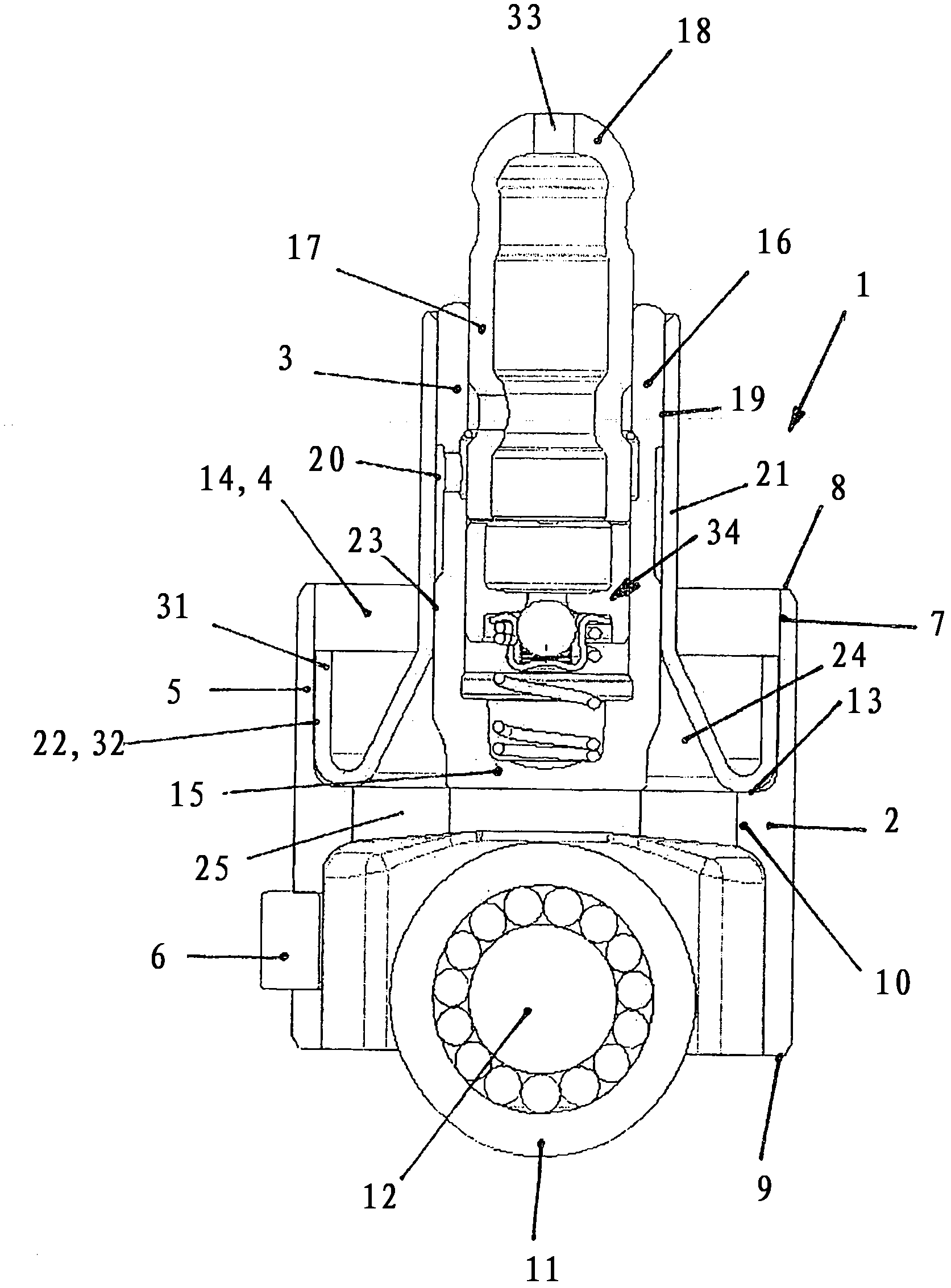

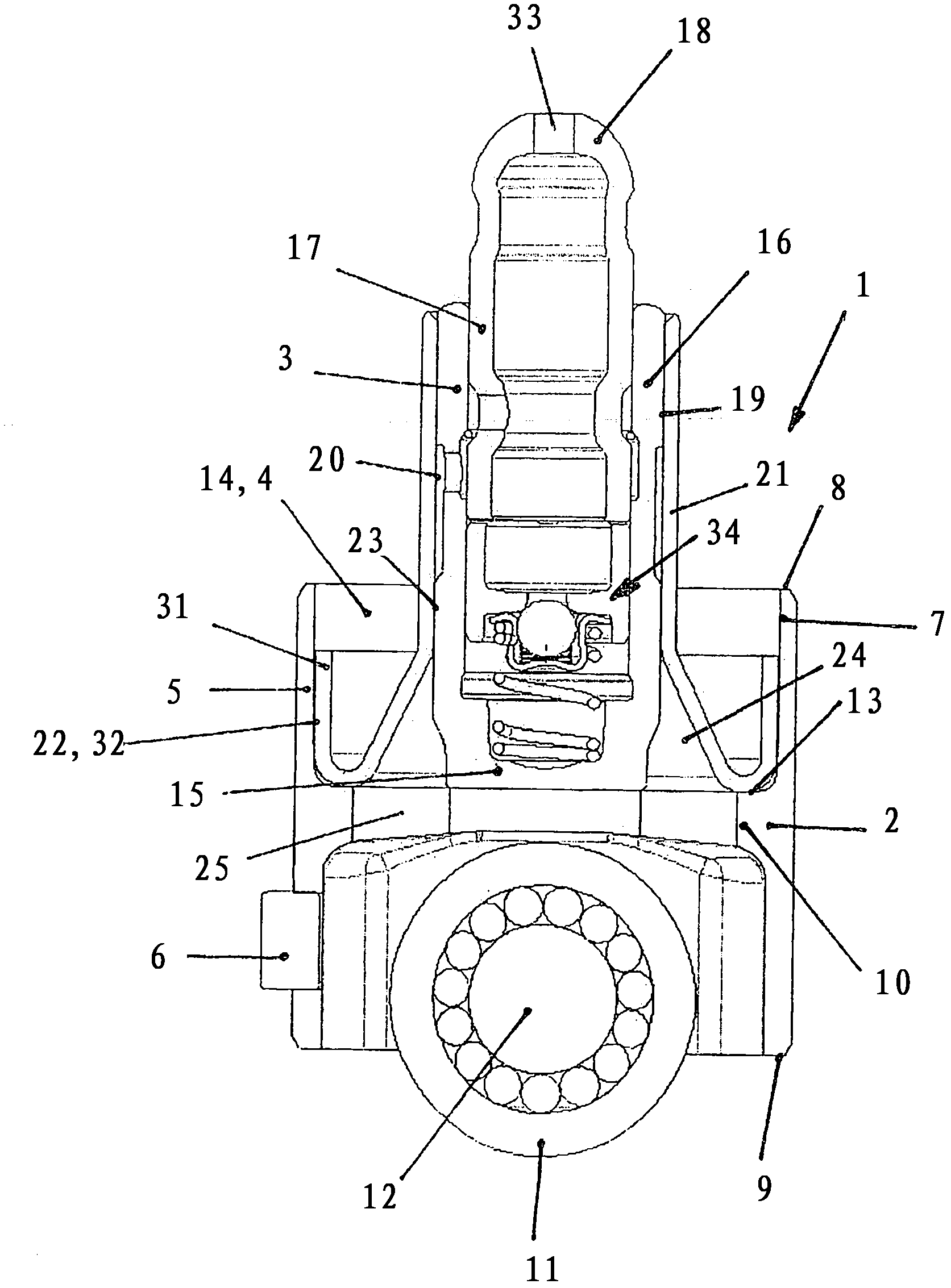

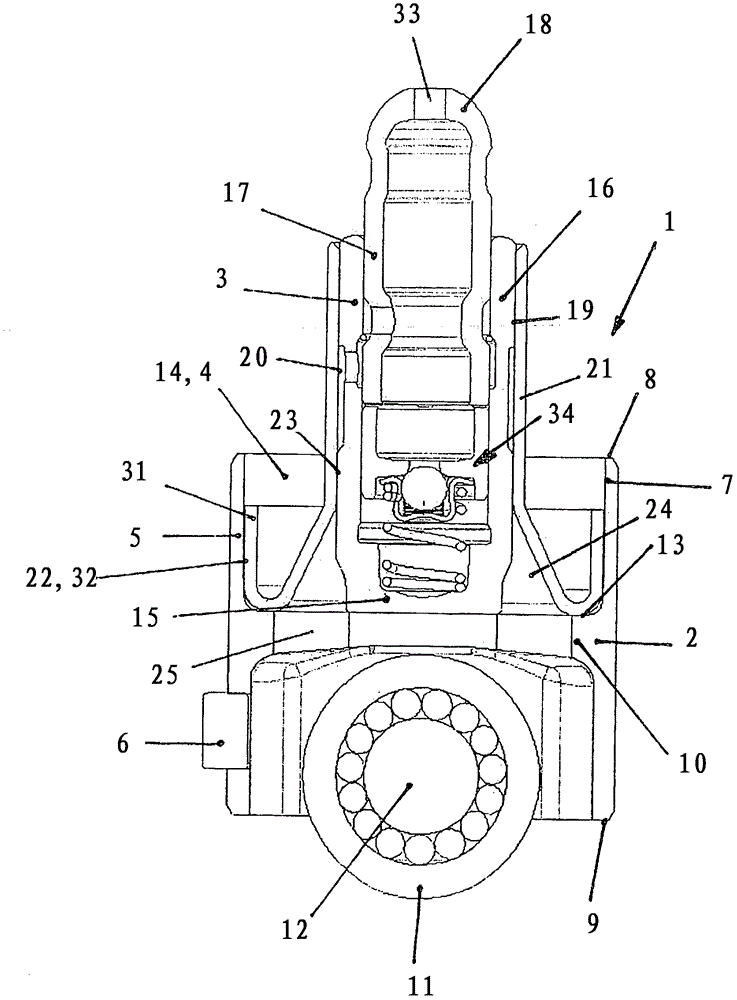

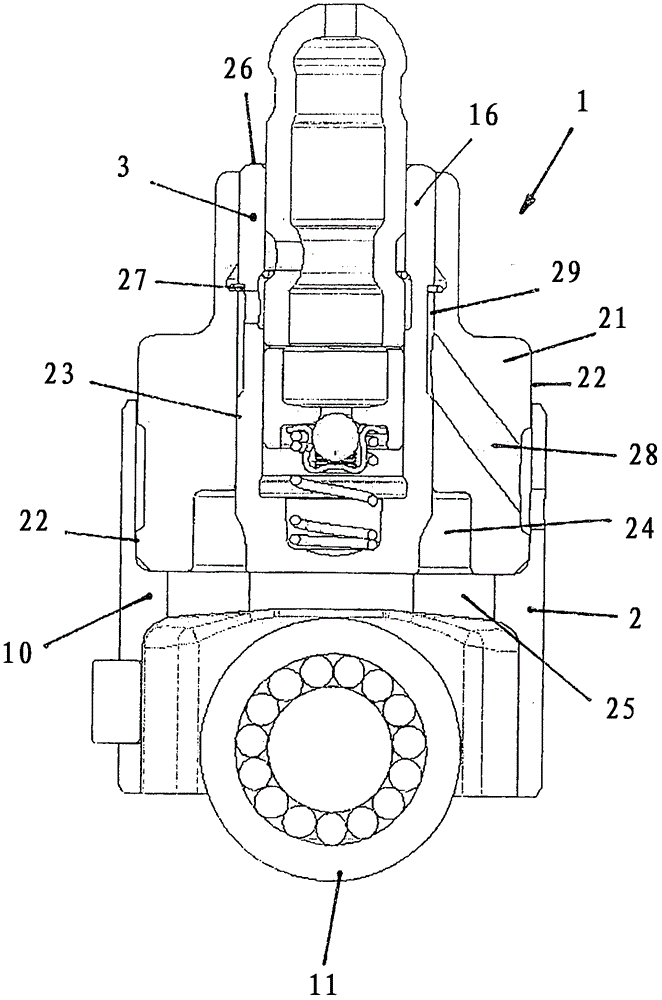

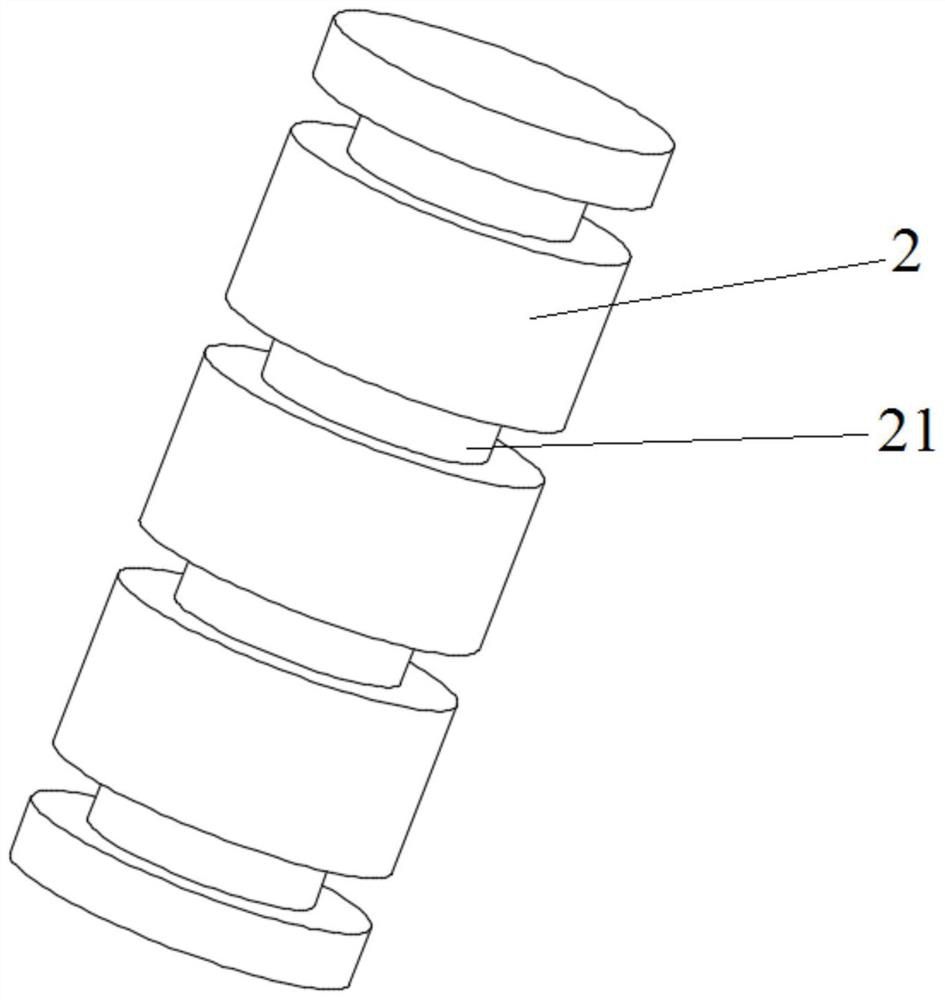

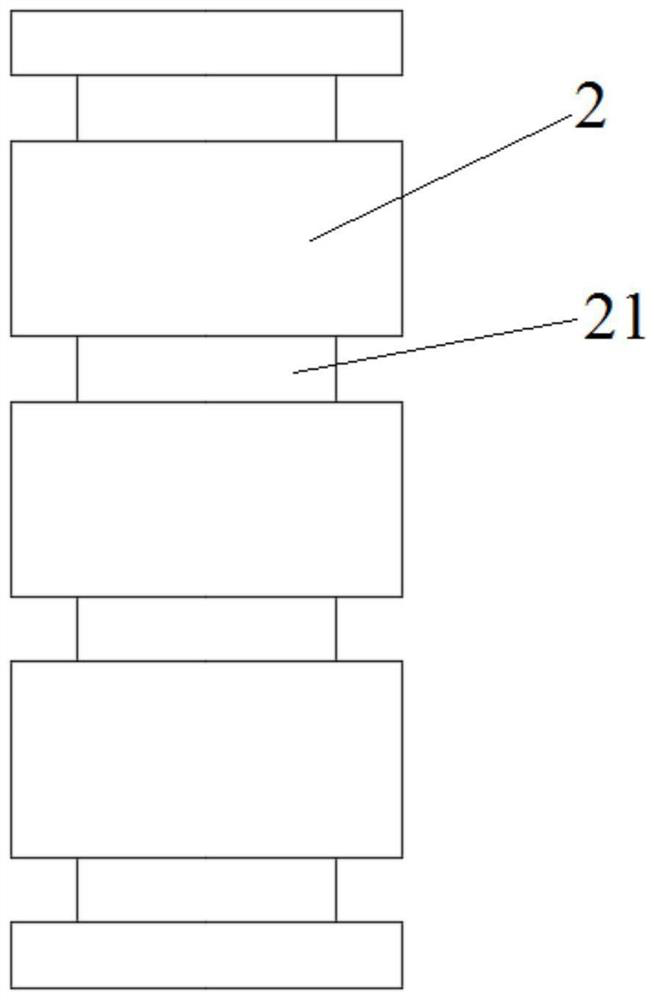

Roller cam follower

InactiveCN102588026ALight in massGuaranteed unchangedValve arrangementsMachines/enginesExternal combustion engineInternal combustion engine

The roller cam follower (1) comprises a hydraulic support unit (3) and a down or lateral cam shaft of an internal combustion engine. The roller cam follower is assembled from a roller shaft (2) for the stroke operation of a piston of a fuel high pressure pump and the hydraulic support unit. An independent claim is also included for a roller shaft has a support unit which is received in sections in a recess.

Owner:SCHAEFFLER TECH AG & CO KG

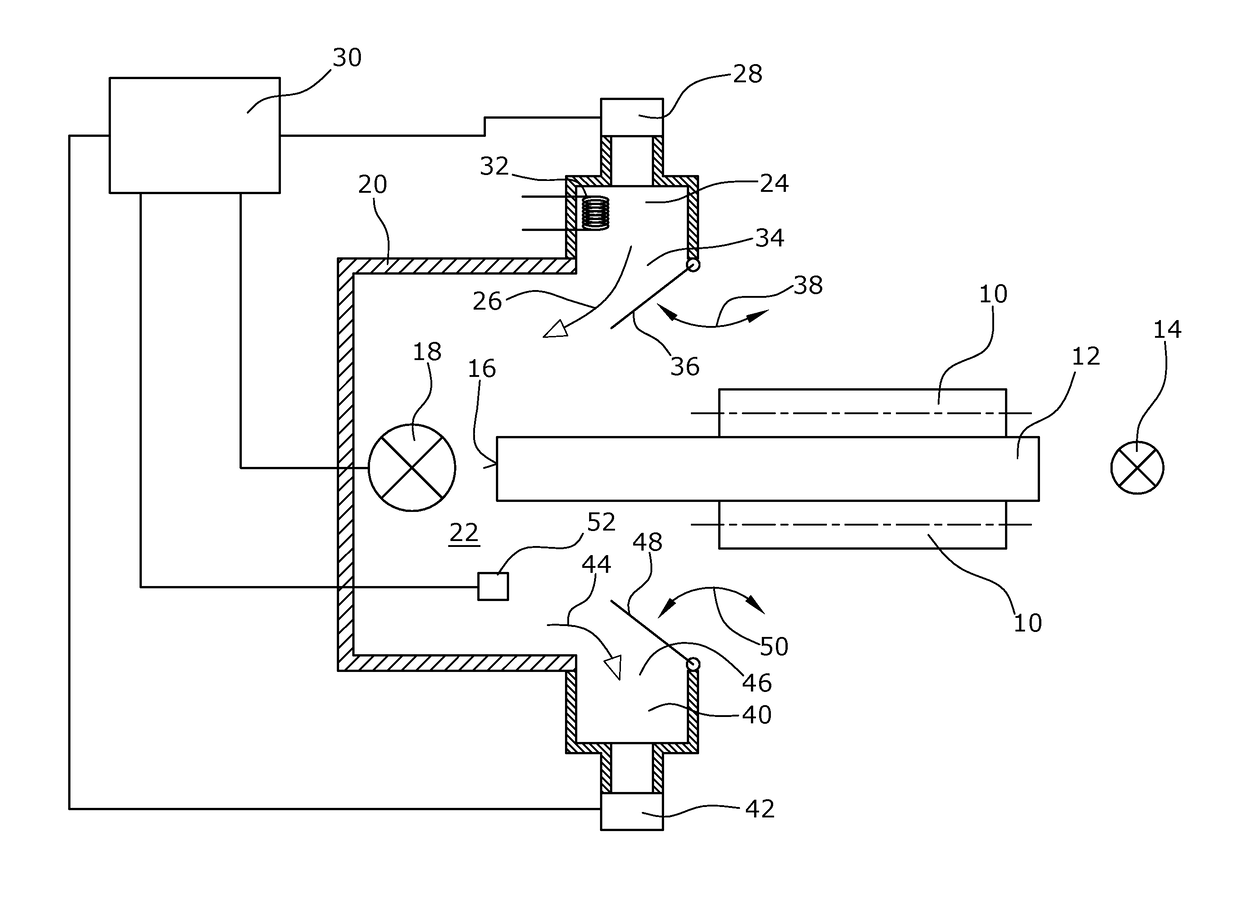

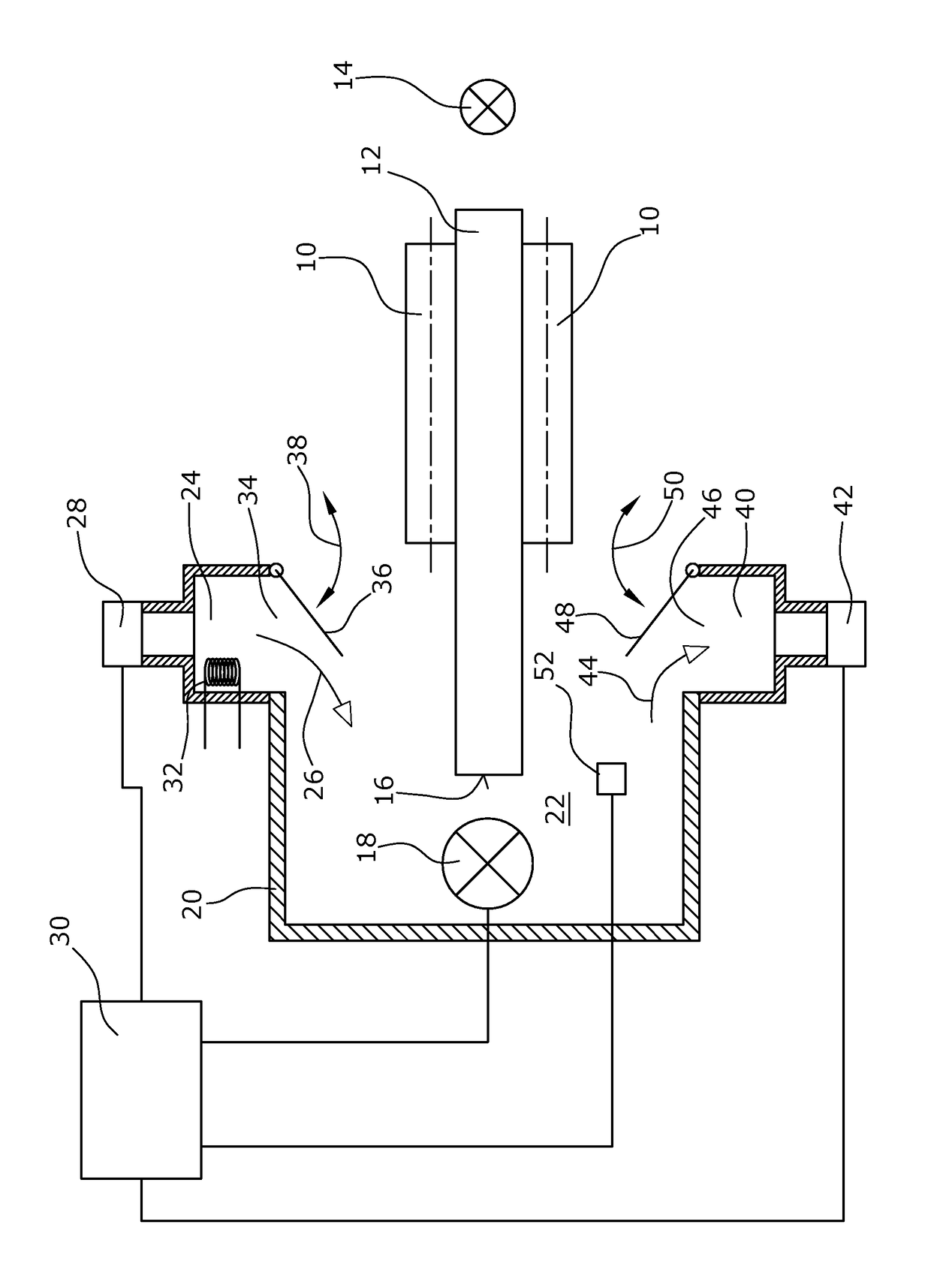

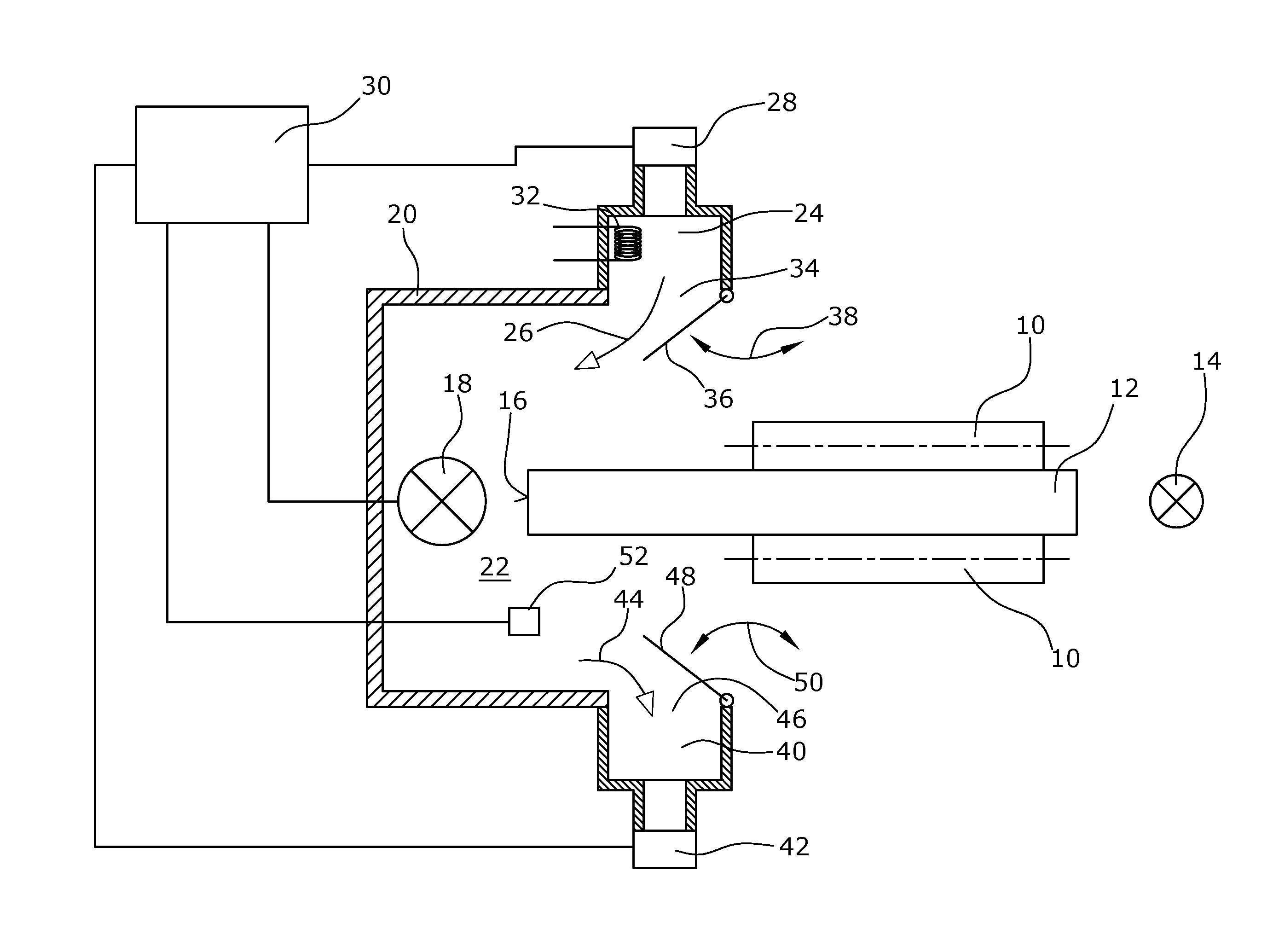

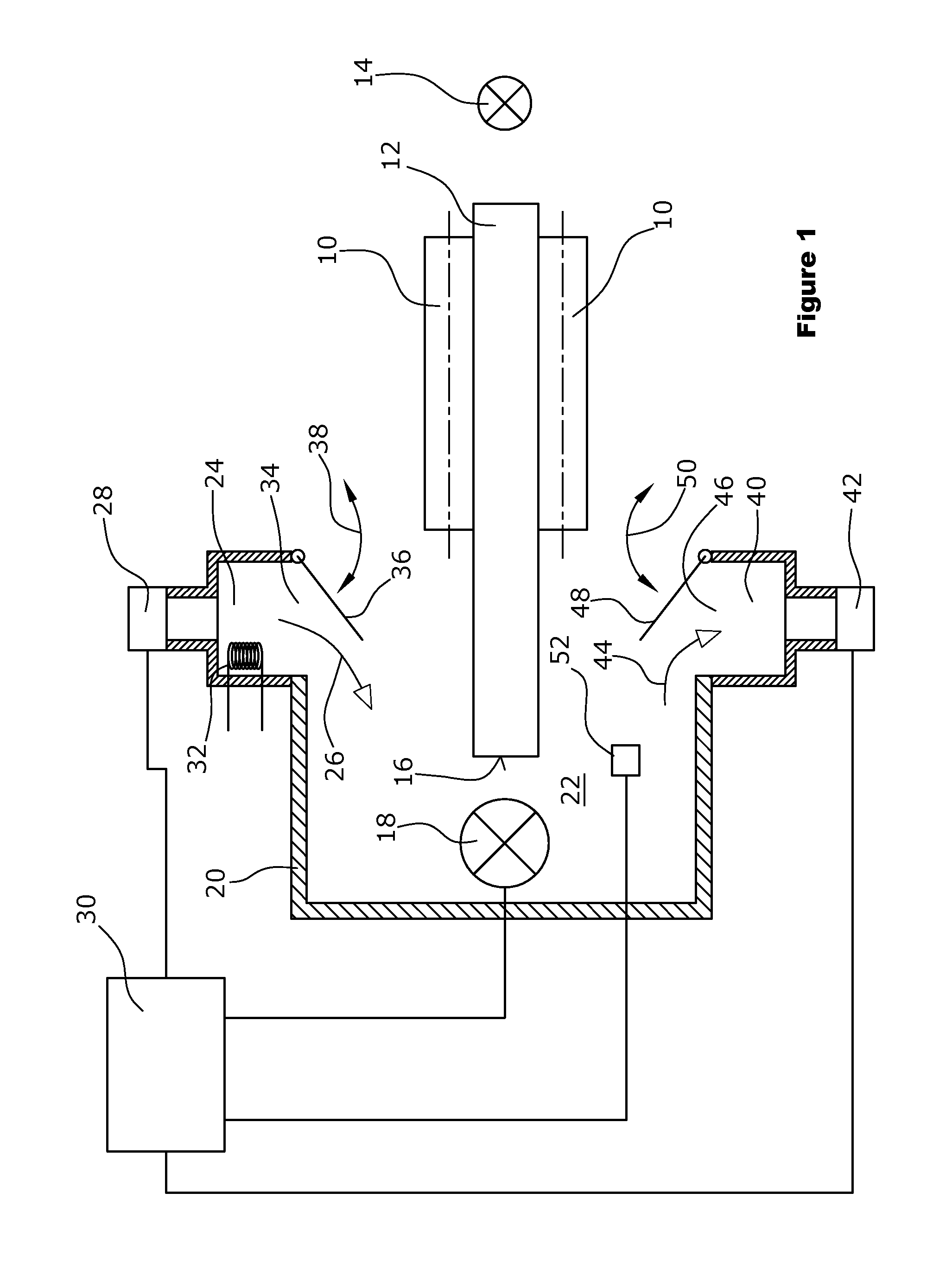

Drying device

InactiveUS9841234B2Short passage timeLong dwell timeDrying solid materials with heatDrying gas arrangementsProcess engineeringAirflow

A drying device for drying coated, elongated work pieces in a continuous process including a transport device for transporting the work piece. For drying an edge or surface of the work piece, heat sources are arranged in a drying chamber. In a drying zone, drying vapor is generated during drying. The vapor is removed by an airflow. The airflow is supplied via a supply channel and fans. A controller is provided to control the fans.

Owner:CEFLA DEUTLAND

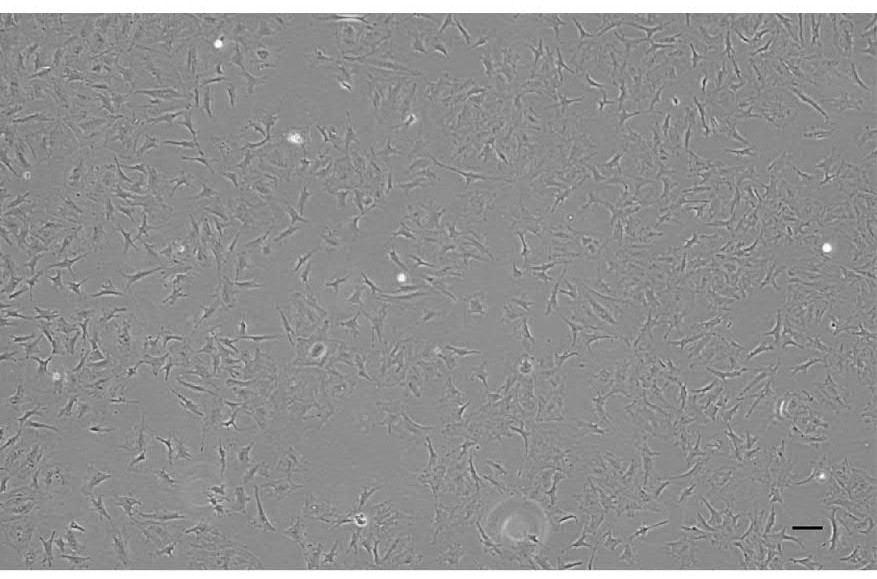

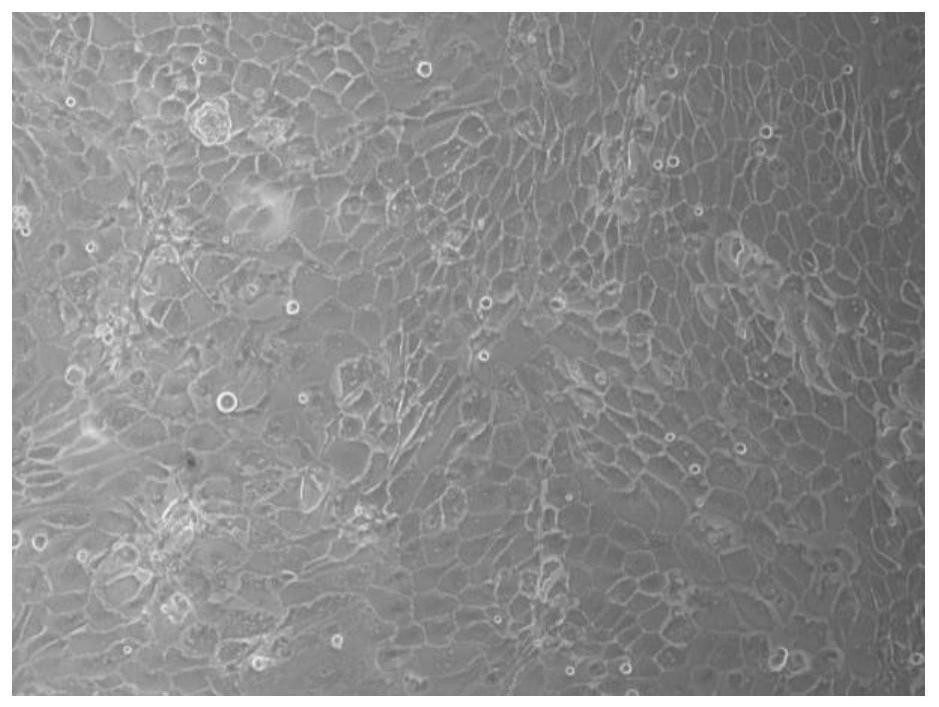

Pseudosciaena crocea muscle cell line and its establishing method

InactiveCN104004707AImprove stabilityGood repeatabilityMicroorganism based processesArtificial cell constructsFibroblastFusiform shape

The invention discloses a Pseudosciaena crocea muscle cell line and its establishing method. The cell line is preserved in China Center for Type Culture Collection on Oct., 31, 2013, and has a preservation registration number of CCTCC NO:C2013158. The Pseudosciaena crocea muscle cell line can be serially passed, can provide a large amount of the Pseudosciaena crocea muscle cell line, and can be used for researching pathogenic characteristics, vaccines, gene functions and breeding; and the Pseudosciaena crocea muscle cell line has excellent properties, is a fibroblast and is soma-fusiform or anomaly triangular, the cytoplasm outwardly stretches to form a plurality of protrusions with different lengths, and the protrusions are arranged in a radial or spiral manner. The Pseudosciaena crocea muscle cell line has the characteristics of strong splitting, short passage time, easy digestion, good adherent rate and starvation resistance. The establishing method has strong repeatability, and the established cell line has a good stability.

Owner:JIMEI UNIV

Drying Device

InactiveUS20160282047A1Dry thoroughlyShort passage timeDrying solid materials with heatDrying gas arrangementsProcess engineeringAirflow

A drying device for drying coated, elongated work pieces in a continuous process including a transport device for transporting the work piece. For drying an edge or surface of the work piece, heat sources are arranged in a drying chamber. In a drying zone, drying vapor is generated during drying. The vapor is removed by an airflow. The airflow is supplied via a supply channel and fans. A controller is provided to control the fans.

Owner:CEFLA DEUTLAND

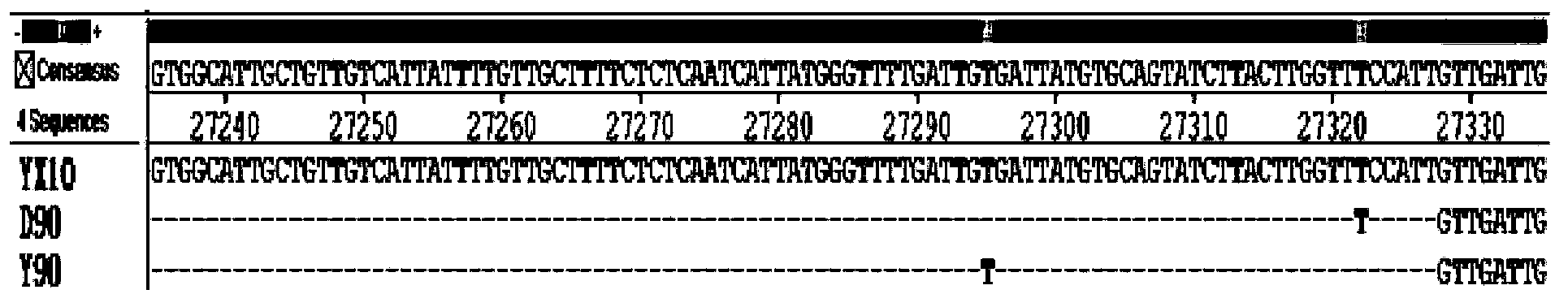

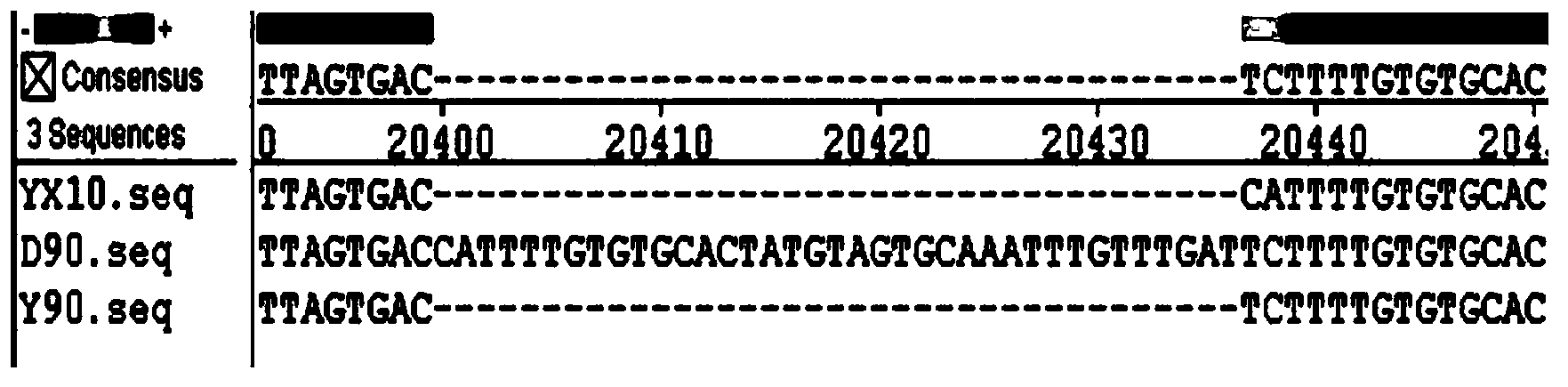

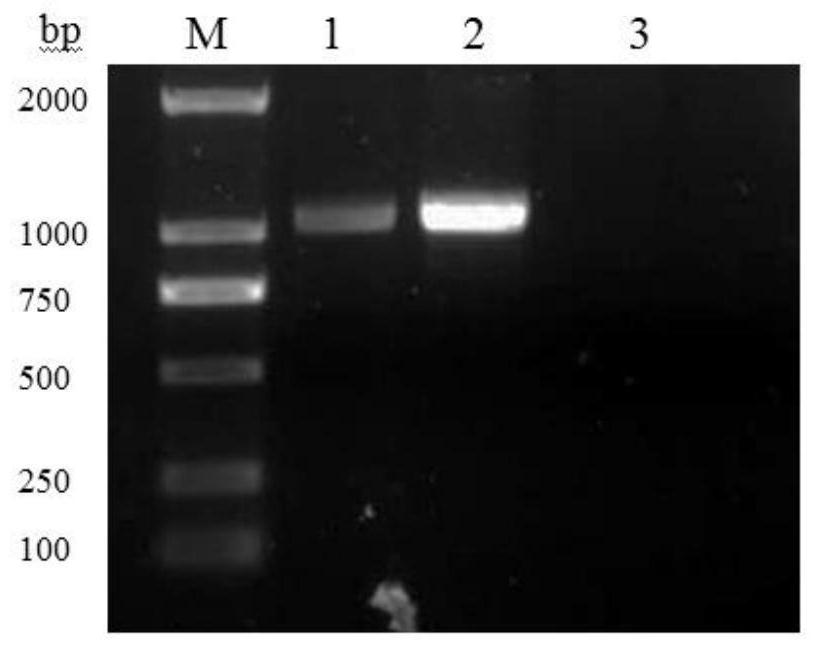

Attenuated method for fowl infectious bronchitis viruses

InactiveCN103397002AShort passage timeReduce lossInactivation/attenuationMicroorganism based processesAllantoic fluidVaccine Immunogenicity

The invention discloses an attenuated method for fowl infectious bronchitis viruses. The method comprises the following steps: the toxic strain YX10 is inoculated on SPF chick embryos, 103.5-4EID50 / 0.2mL of the toxic strain is inoculated on every embryo; after cultured for certain time, the chick embryos are placed at the temperature of minus 20 DEG C for half an hour; allantoic fluids are collected in sterile conditions; the passage of the next generation is carried out; the culture temperature of the first generation to the tenth generation is 37 DEG C and the culture time is 48 h; the culture temperature of the eleventh generation to the fourteenth generation is lowered by 1 degree per generation and the culture time is 48 h; from the fifteenth generation, the culture temperature is 32 DEG C, and the culture time is 32-48 h. The method can save the passage time effectively, and reduces the loss of immunogenicity. The method is beneficial to develop novel vaccines in time and effectively.

Owner:WENS FOOD GRP CO LTD +1

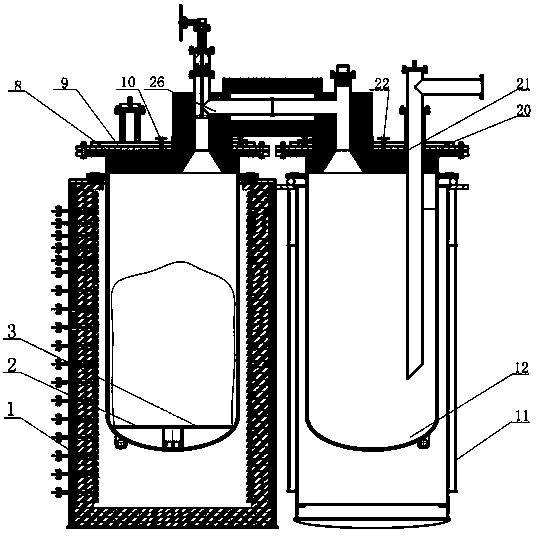

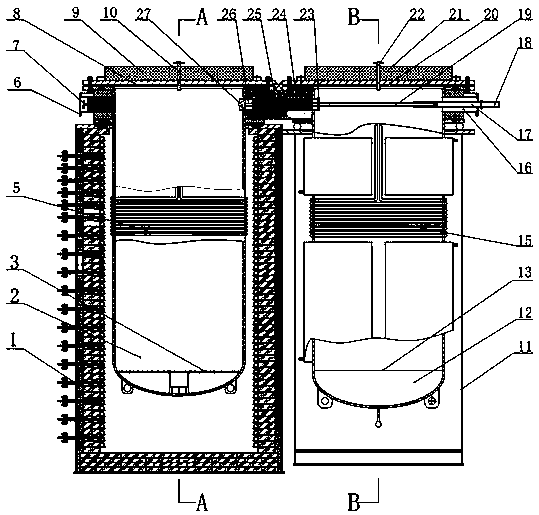

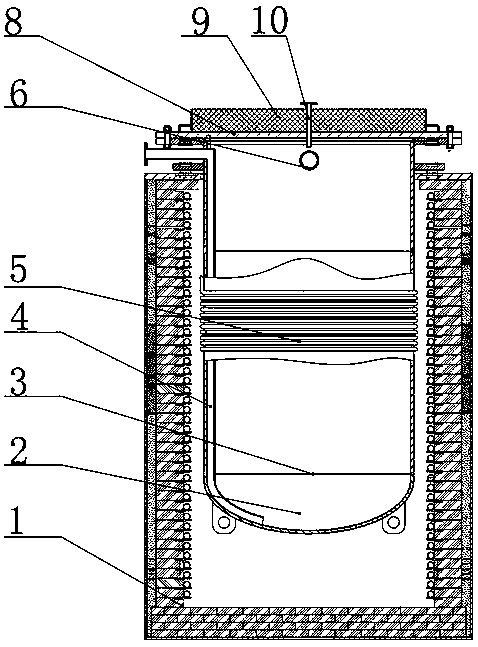

Sponge titanium reduction distillation system with linear-shaped passage

ActiveCN109022789AReduce cooling areaReduced transit timeProcess efficiency improvementDistillationChloride

The invention provides a sponge titanium reduction distillation system with a linear-shaped passage. The sponge titanium reduction distillation system comprises a heating furnace, a hot end reactor, afirst large cover, a cold end protection sleeve, a cold end reactor, a second large cover, a heat dissipation system, a cooling system, a first sieve plate, a first magnesium chloride discharging pipe, a first heat preservation layer, a first charging pipe, a second sieve plate, a second magnesium chloride discharging pipe, a second heat preservation layer, a second charging pipe, the linear-shaped passage and a third heat preservation layer; a first valve seat is arranged between double flanges of the hot end reactor, a second valve seat is arranged between double flanges of the cold end reactor, and a high temperature valve is mounted in the second valve seat; and the high temperature valve comprises a threaded casing, a screw rod, a sealing valve plate, a shaft rod and a fourth heat preservation layer. The large cover is greatly simplified, the heat preservation measure of the large cover can be conveniently enhanced, heat dissipation can be significantly lowered, the length of thepassage is greatly decreased, thus the heat dissipation area of the passage is shortened, the passing time of magnesium steam and magnesium chloride steam is short, the temperature drop is low, the heating power of the passage can be significantly lowered, and even only heat preservation is needed without heating.

Owner:谢以贵

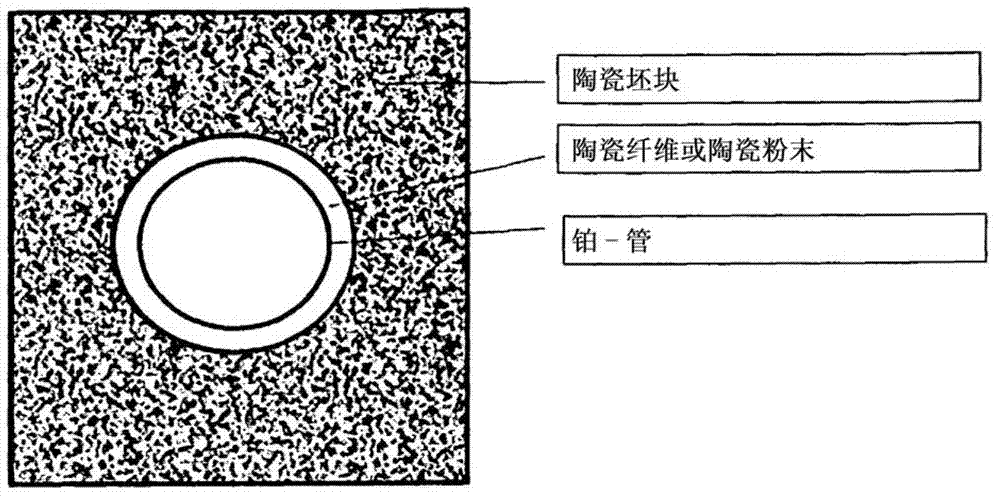

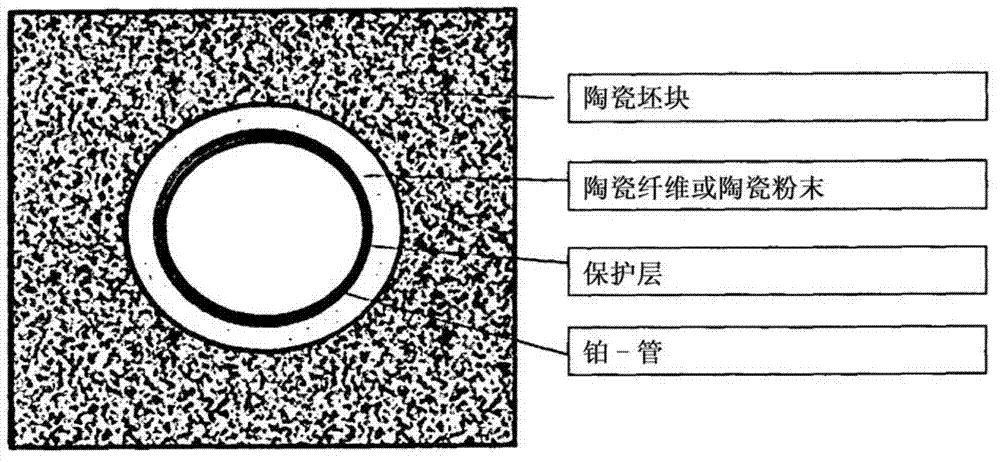

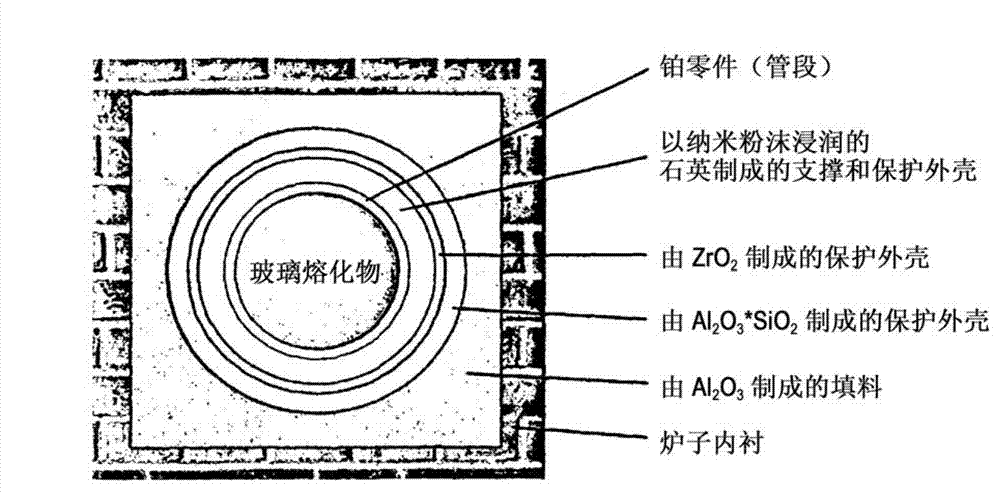

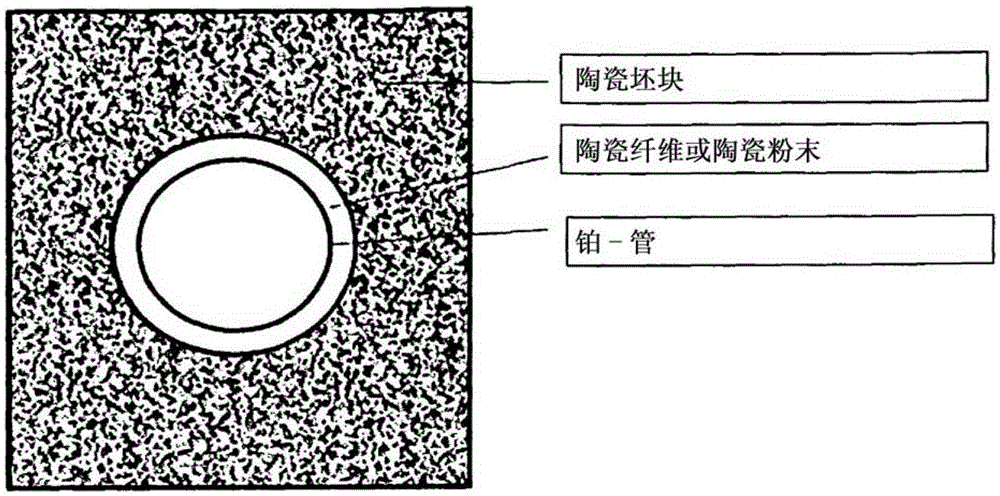

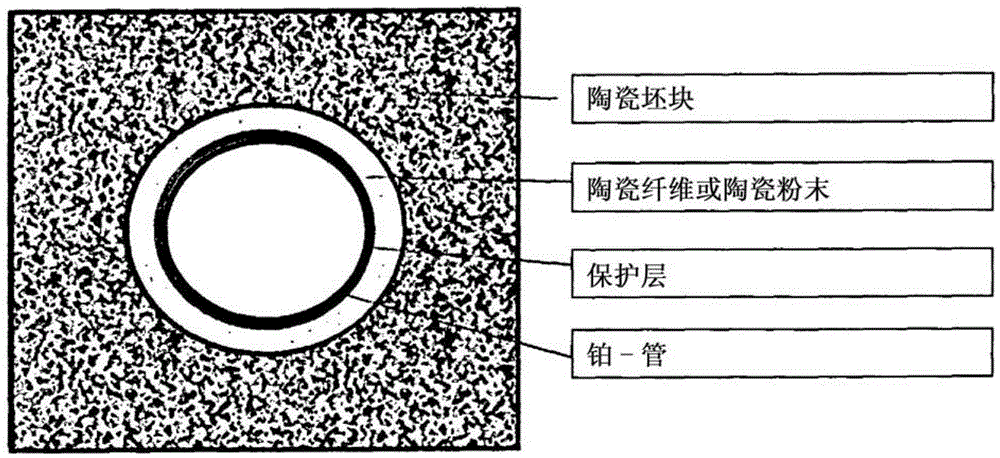

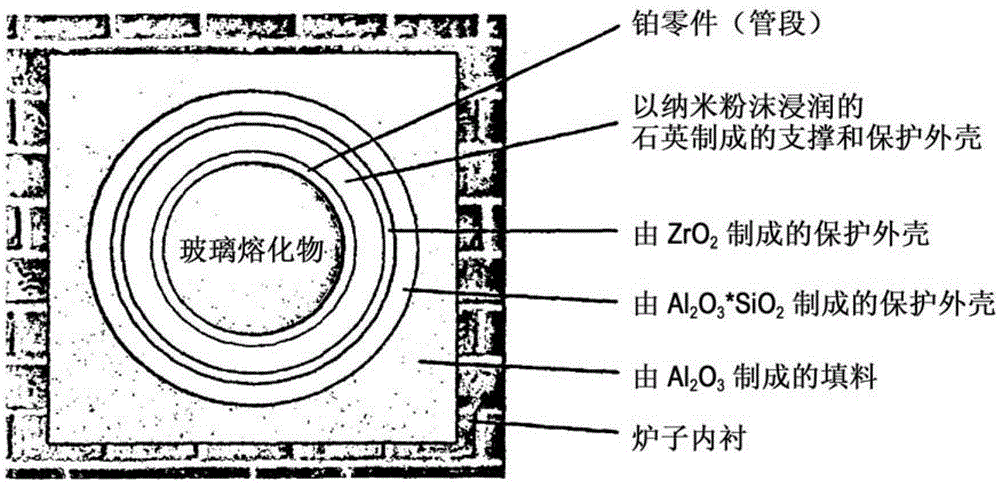

Reduction of pt and rh evaporation losses at high temperatures by using a barrier layer

InactiveCN103168008AReduce viscosityEfficient purificationForehearthsGlass furnace apparatusPlatinumAlloy

Parts made of platinum or a Pt alloy, the outer surface of which comes in contact with an oxidizing atmosphere during operation and is covered with an open-cell ceramic or quartz layer, the pores containing a material that melts at the operating temperature as an infiltration material, are protected against loss caused by evaporation when used in an oxidizing atmosphere at temperatures exceeding 1200 DEG C. A method for reducing the evaporation rate out of platinum and Pt alloys in an oxidizing atmosphere comprises the steps of A. applying an open-cell quartz or ceramic layer, B. infiltrating said quartz or ceramic layer with a material melting at a lower temperature than the ceramic material such that pore spaces of the open-cell ceramic layer are partially or entirely filled by the infiltration material, C. use at temperatures exceeding 1200 DEG C.

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

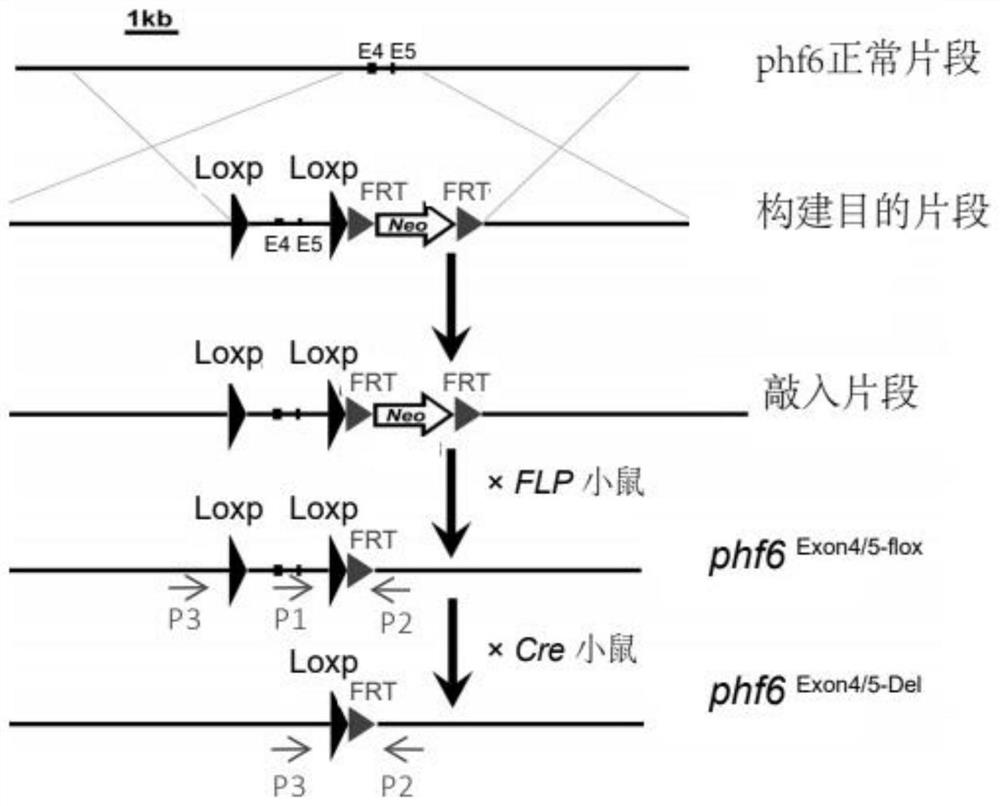

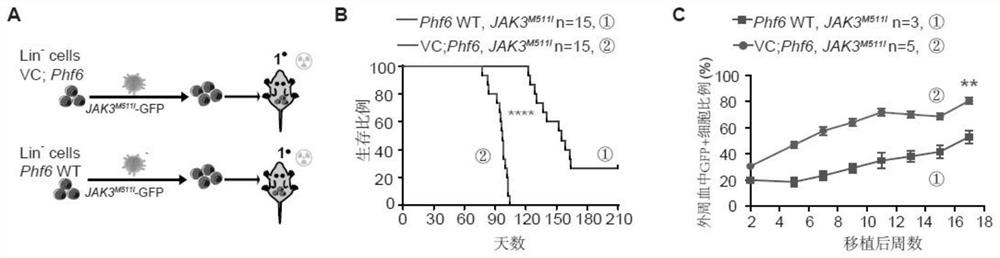

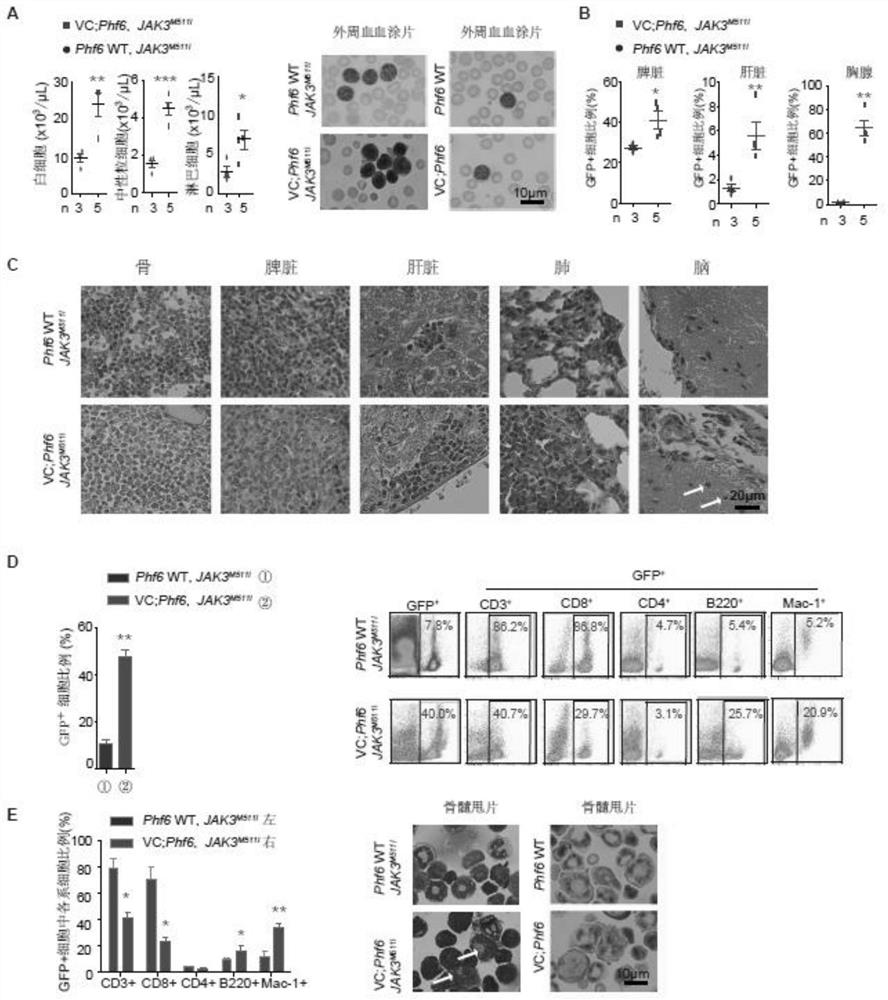

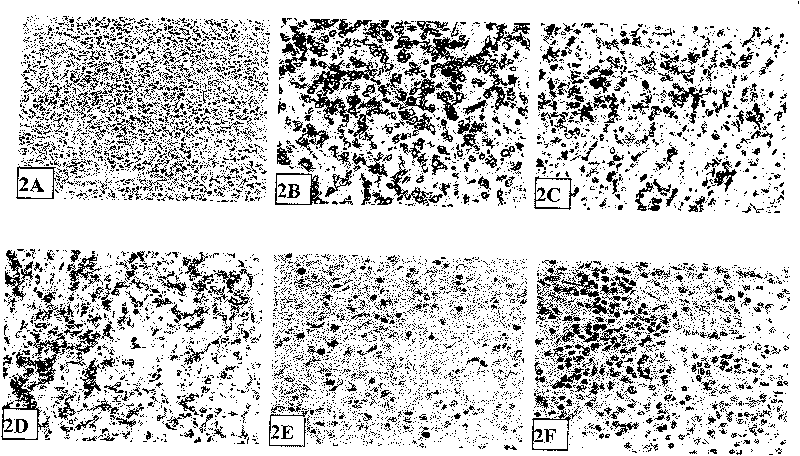

Construction method and application of PHF6 <delta> and JAK3<M511I> double-mutation acute T lymphocytic leukemia mouse model

ActiveCN113549655AShort passage timeStable proliferationCompounds screening/testingTransferasesLymphocytic cellDouble mutation

The invention discloses a construction method and an application of a PHF6 <delta> and JAK3<M511I> double-mutation acute T lymphocytic leukemia mouse model. The preparation method comprises the following steps: utilizing a Vav1-Cre mouse to mate with a Phf6<fl / fl> mouse to obtain Vav1-Cre; a Phf6<fl / Y> (Phf6<- / Y>) male mouse; mating the Mx1-Cre mouse and the Phf6<fl / fl> to obtain Mx1-Cre; Phf6<fl / Y>male mouse; respectively enriching Lin-cells in bone marrow of two male mice, infecting retroviruses overexpressing GFP-JAK3M511I, and transplanting GFP + cells into receptor mice irradiated by a lethal dose through caudal vein injection, so as to construct two T-ALL leukemia mouse models. The model provided by the invention can be rapidly passed in mice, simulates the leukemia process of a T-ALL patient with PHF6 gene and JAK3 gene double mutation, and is used for targeted therapy drug screening and curative effect evaluation.

Owner:INST OF HEMATOLOGY & BLOOD DISEASES HOSPITAL CHINESE ACADEMY OF MEDICAL SCI & PEKING UNION MEDICAL COLLEGE

Dental pulp stem cell separation and culture method

PendingCN109897821ADigest thoroughlyMore totalSkeletal/connective tissue cellsTremellaAdditive ingredient

The invention discloses a dental pulp stem cell separation and culture method. The method comprises steps as follows: separation of dental pulp tissue, enzymolysis of the dental pulp tissue with IV type collagenase, V type collagenase and pancreatin mixed enzyme with the mass volume concentration of 0.05%-0.5%, primary culture of dental pulp stem cells and adding of cell growth factors, glutamine,decavitamin, insulin, tremella polysaccharide, a codonopsis tangshen extract, a dendrobium officinale extract and other nutritional ingredients. The method has the advantages as follows: the dental pulp tissue is more thoroughly digested, and the total number of the obtained dental pulp stem cells is larger; the total number of the obtained dental pulp stem cells is increased, the cell viabilityof the dental pulp stem cells is increased, besides, the passage time of the stem cells is shortened, and the isolated culture cycle of dental pulp stem cells is greatly shortened.

Owner:广州南医大生物工程有限公司

Intelligent traffic light capable of adjusting passing time at any moment according to waiting vehicles

InactiveCN104835330AReduce waiting timeEasy and quick passControlling traffic signalsControl systemGreen-light

The invention discloses an intelligent traffic light capable of adjusting passing time at any moment according to waiting vehicles. The intelligent traffic light comprises a traffic light unit, a traffic light intelligent chip control system and a camera. The intelligent traffic light is characterized in that traffic crossroads can be intelligently managed through the intelligent traffic light, and the intelligent chip identifies the number of the vehicles waiting for a red light through the camera and displays the time of a green light, so that the waiting time of a driver can be reduced, the traffic pressure of the crossroads can be alleviated, the traffic can be alleviated and can be controlled completely without errors, protection is provided for the traffic vehicles, and the safety is guaranteed.

Owner:牛淑刚

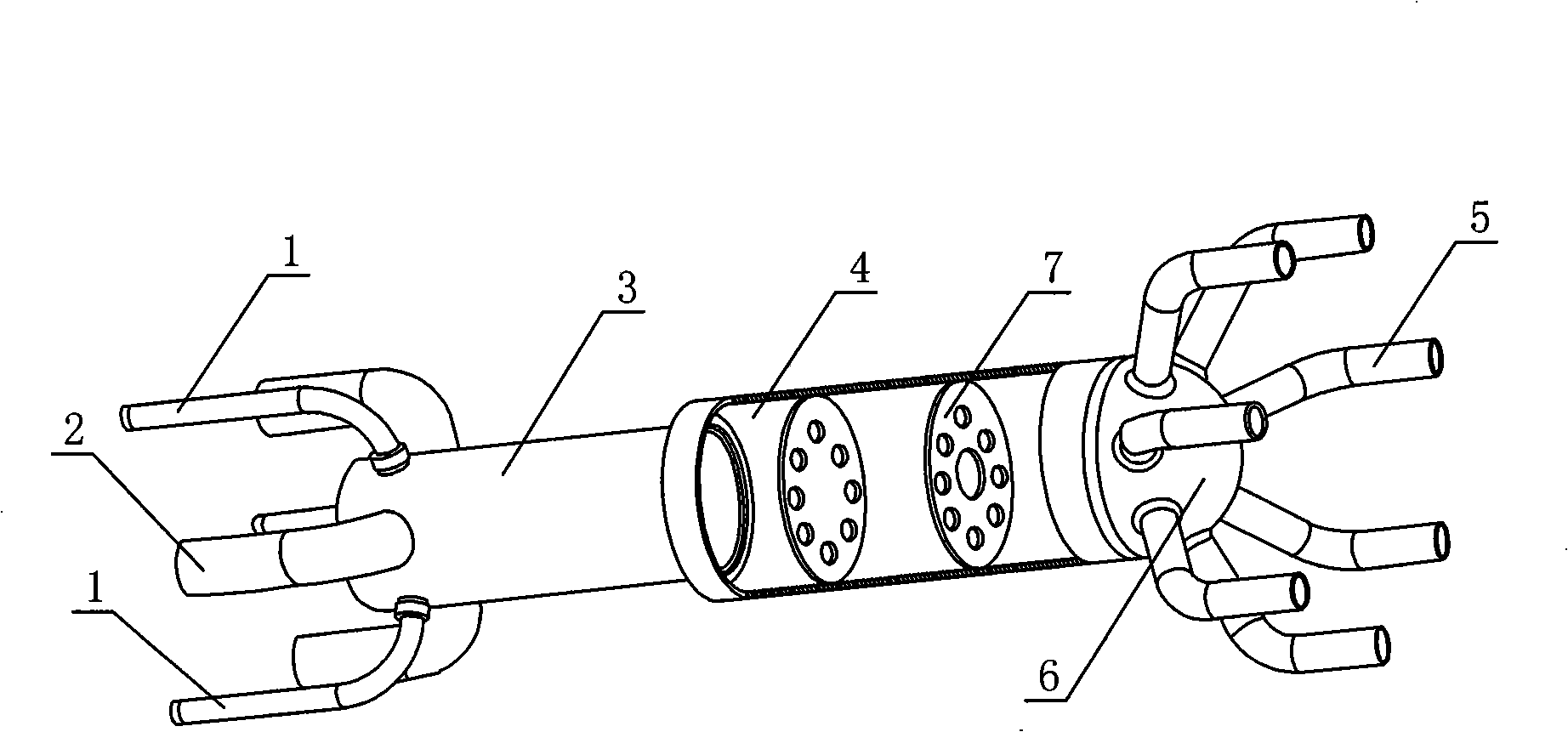

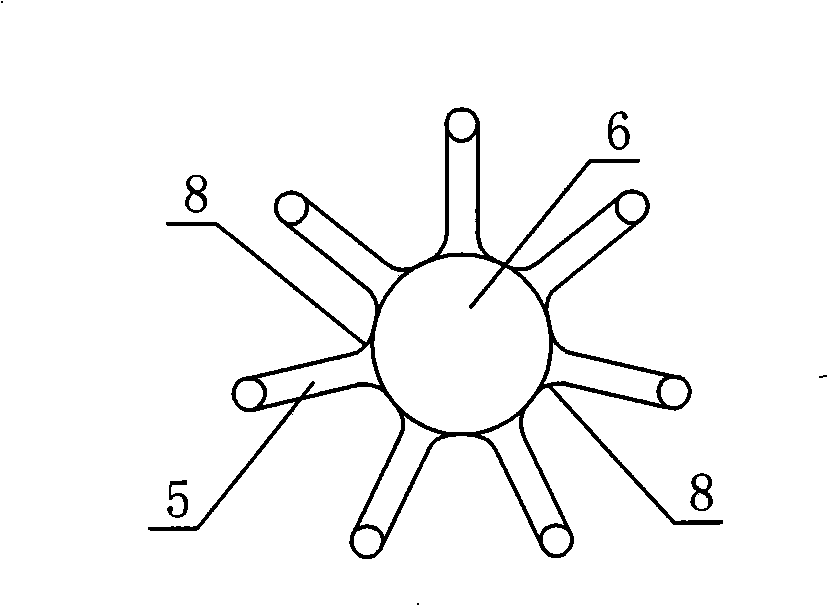

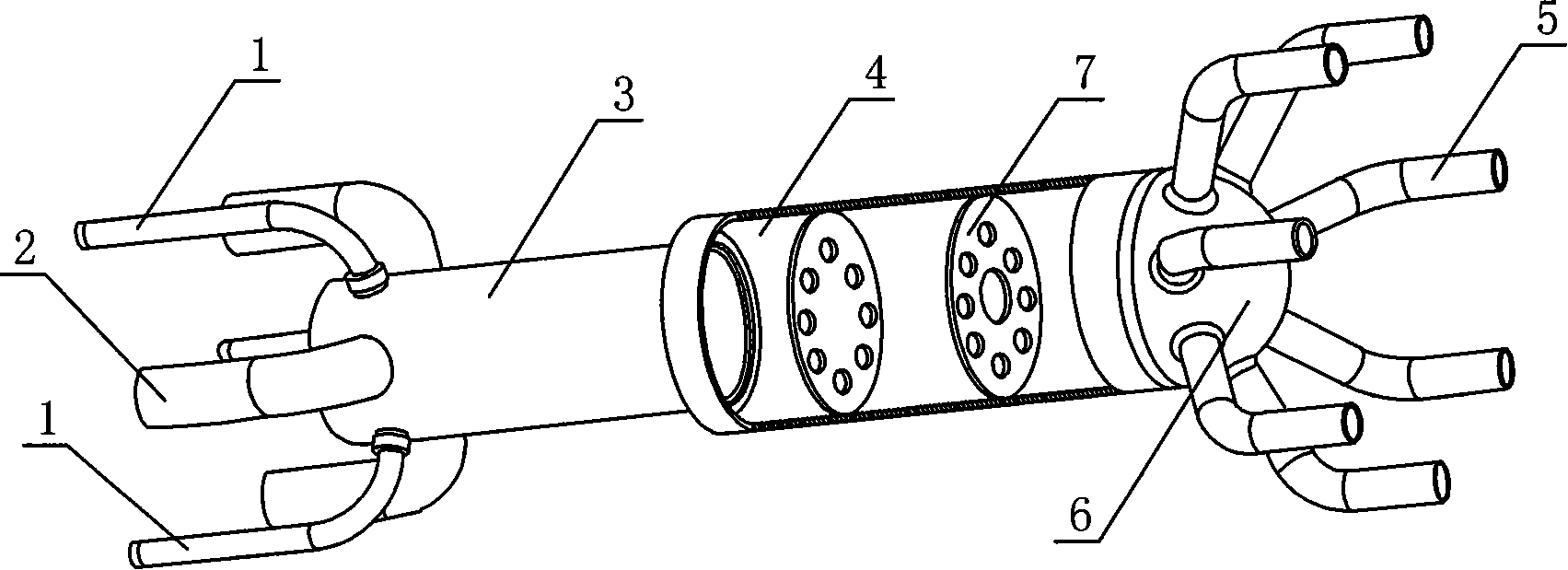

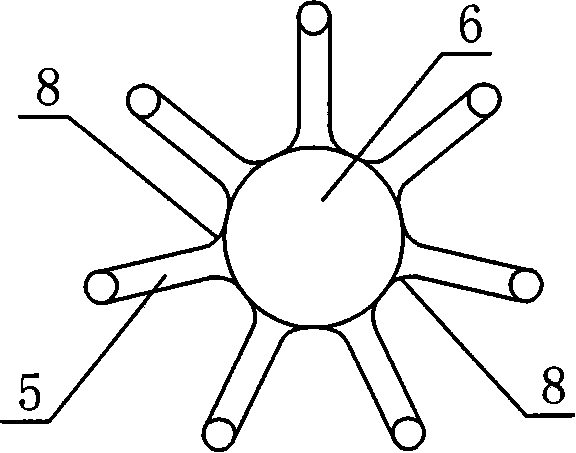

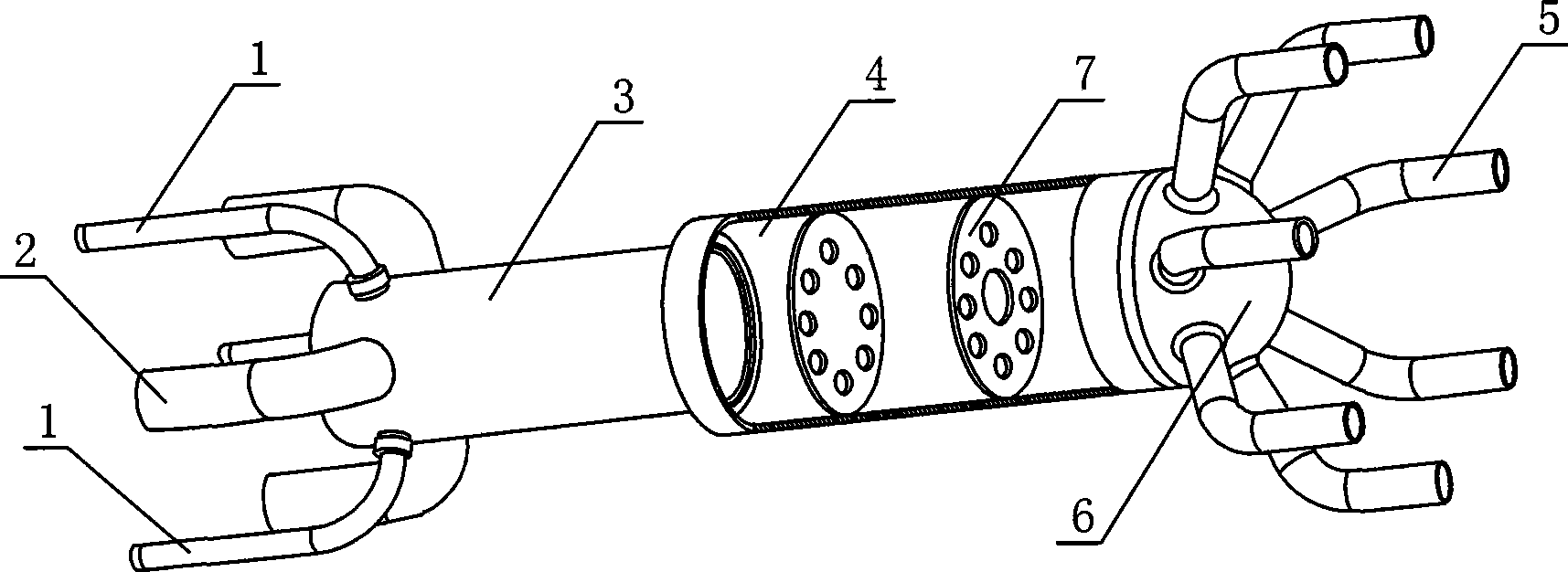

Temperature field adjustable type high efficiency burnt gas pulsating combusting device

InactiveCN101334216AImprove combustion efficiencyImprove combustion intensityWater heatersGaseous fuel burnerCombustorCombustion chamber

The invention relates to a highly efficient fuel gas pulsating combustor with an adjustable temperature field, which is composed of fuel gas inlet pipes, air inlet pipes, a combustion chamber, a heat releasing chamber and a furnace pipe, wherein, at least a group of fuel gas inlet pipes and air inlet pipes are arranged and connected at intervals at a tubular end of the combustion chamber, the other end of the combustion chamber is connected with the heat releasing chamber, and a plurality of branch furnace pipes are radially connected on an arc shaped end socket of the outlet of the heat releasing chamber. The diameter of the cylinder of the heat releasing chamber connected with the combustion chamber is larger than that of the combustion chamber, at least one flow flexing plate is radially arranged inside the heat releasing chamber, and isomorphic or heterogeneous pore passages are arranged on each flow flexing plate. The highly efficient fuel gas pulsating combustor with the adjustable temperature field of the invention has the advantages of high combustion efficiency, combustion intensity and heat exchange performance, low pollutant content in the discharged flue gas, long service life and improved working efficiency.

Owner:大庆石油化工机械厂有限公司

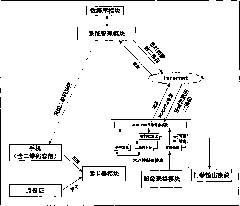

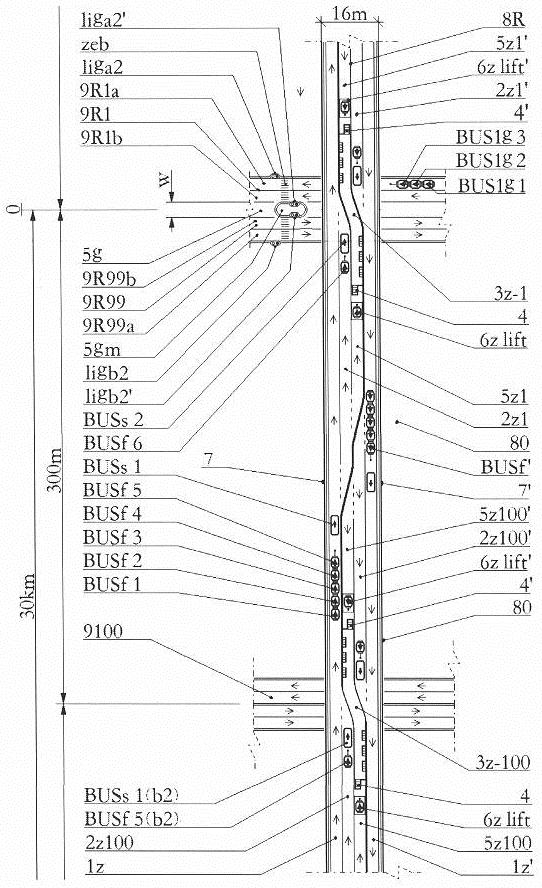

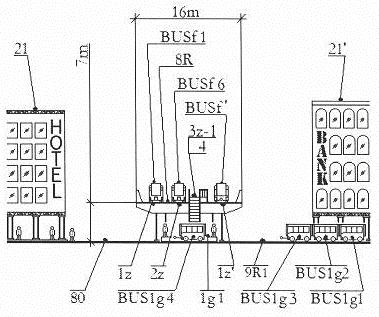

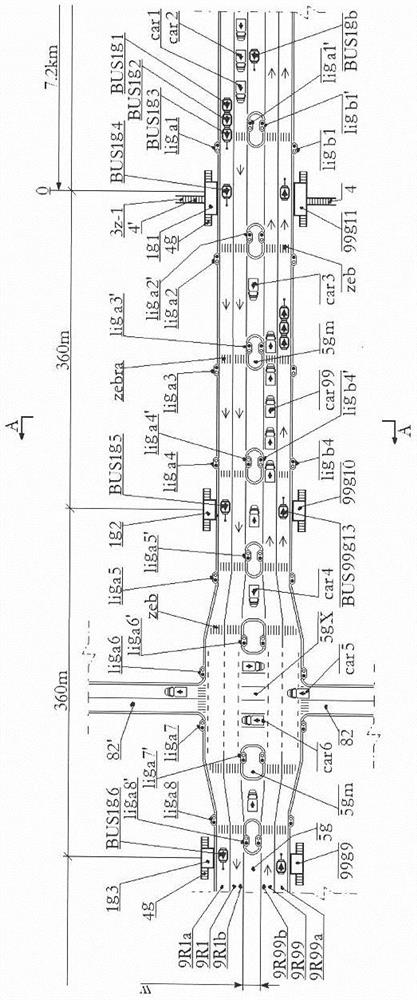

Ground one-way loop for following and transferring buses

The invention discloses a ground one-way loop for following and transferring buses, and belongs to the technical field of urban traffic and urban planning. A bus is transferred along with a car, which is called a fast bus for short. The problem to be solved is to provide a satisfactory ground operation road for express buses. According to the technical scheme, multiple express vehicles are connected to form an express vehicle queue, the running express vehicle queue serves as a signal source, traffic lights on the two sides of a ground one-way loop are sequentially triggered through a traffic light remote control system, green light continuous running of one road of the express vehicle queue is guaranteed, and it is guaranteed that express vehicle single machines are connected from the front and join the express vehicle queue; and ensuring that the express single machines are disconnected from the tail of the queue and exit the express queue. And it can be ensured that passengers transfer between the front and rear cars of a traveling fast car queue on both straight and curved road sections. Ground social vehicle driving and pedestrian walking are both considered. The system has the advantages that the ground is in a one-way loop, the station spacing is 360 m, three express vehicles are connected to run in a queue, the average speed per hour is 36 km / h, the queue length is 15 m, the passenger carrying capacity is 60, the departure interval is 2 min, and the one-way passing capacity is 60 persons * 30 * 36 km / h.

Owner:田耕

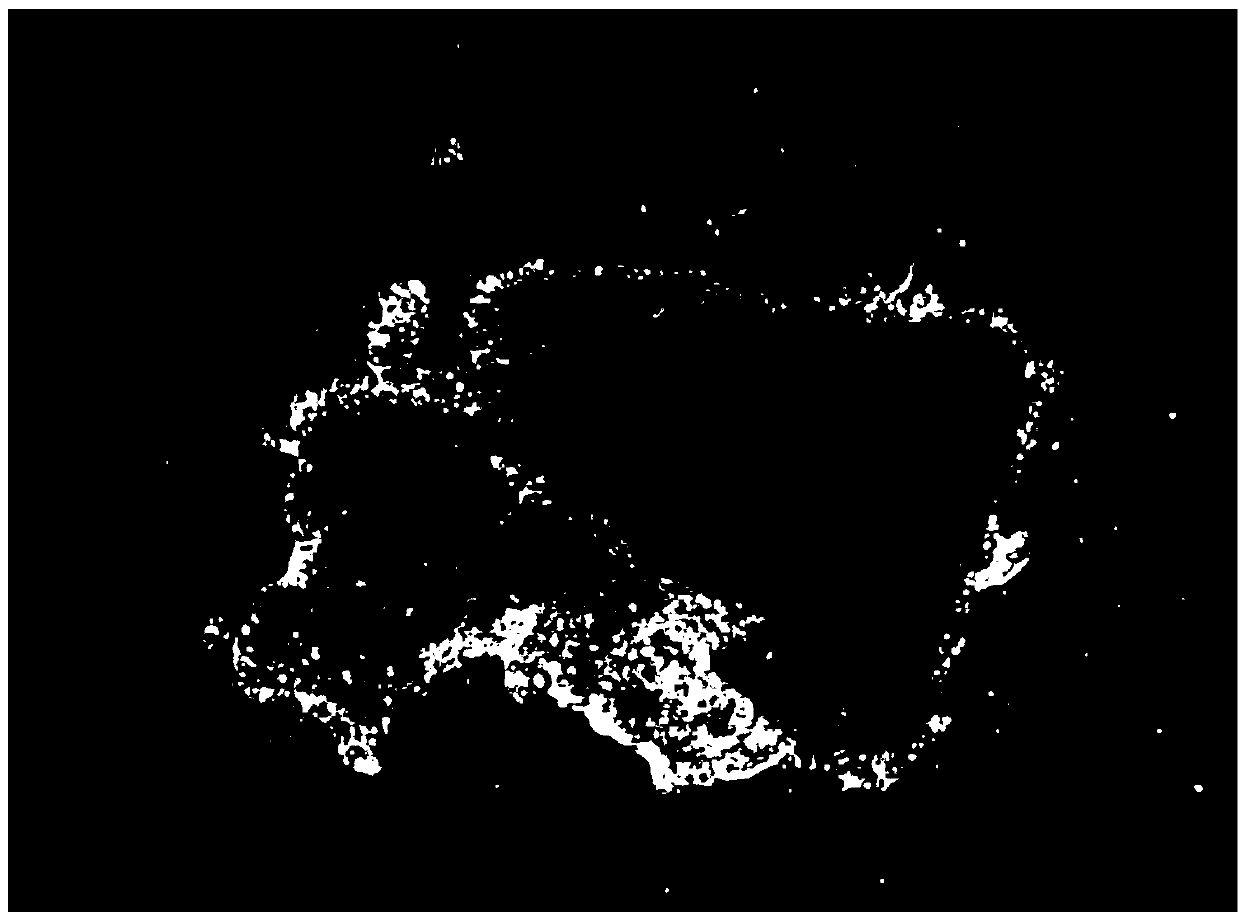

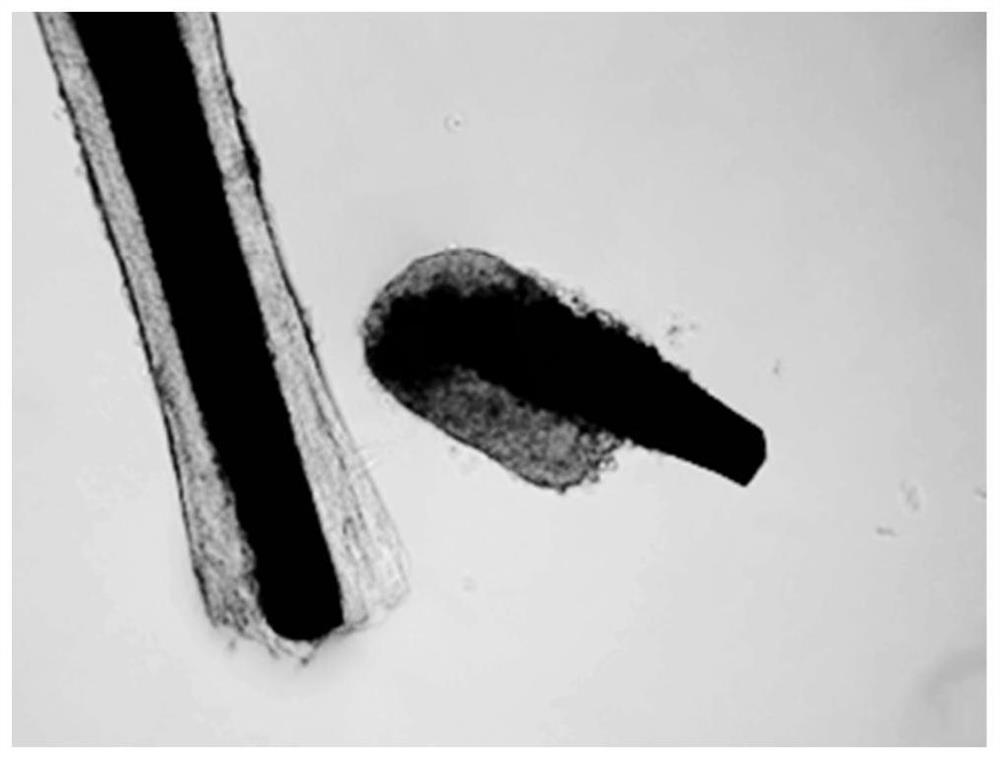

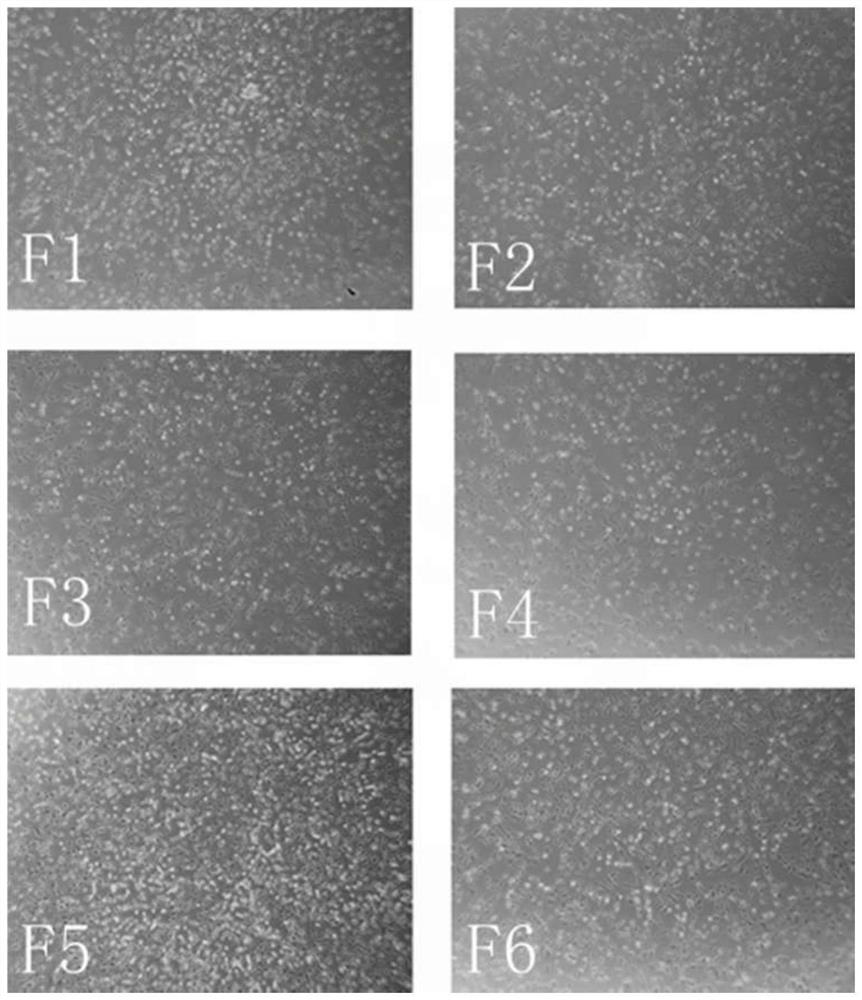

Pomfret muscle tissue cell line

PendingCN113637632AShort passage timeGood characterCell dissociation methodsCulture processBiotechnologyMuscle tissue

The invention provides a pomfret muscle cell line. The pomfret muscle cell line is a pomfret muscle cell PaM with the preservation number of CCTCC NO: C2021154. The pomfret muscle tissue cell line provided by the invention can be continuously passed to 50 generations and is kept stable so far, and a large number of stable pomfret muscle cells can be provided for nutrition metabolism, functional gene research, breeding research and the like. The provided cell line is excellent in character and is a fibroblast, the cell is fusiform or irregular triangle-shaped, a plurality of irregular bulges extend outwards from a cell body, and the cells are tightly arranged. The cell is short in generation time, can be cryopreserved and recovered, and and can perform various molecular biology experiments such as siRNA interference, plasmid transfection and the like.

Owner:NINGBO UNIV

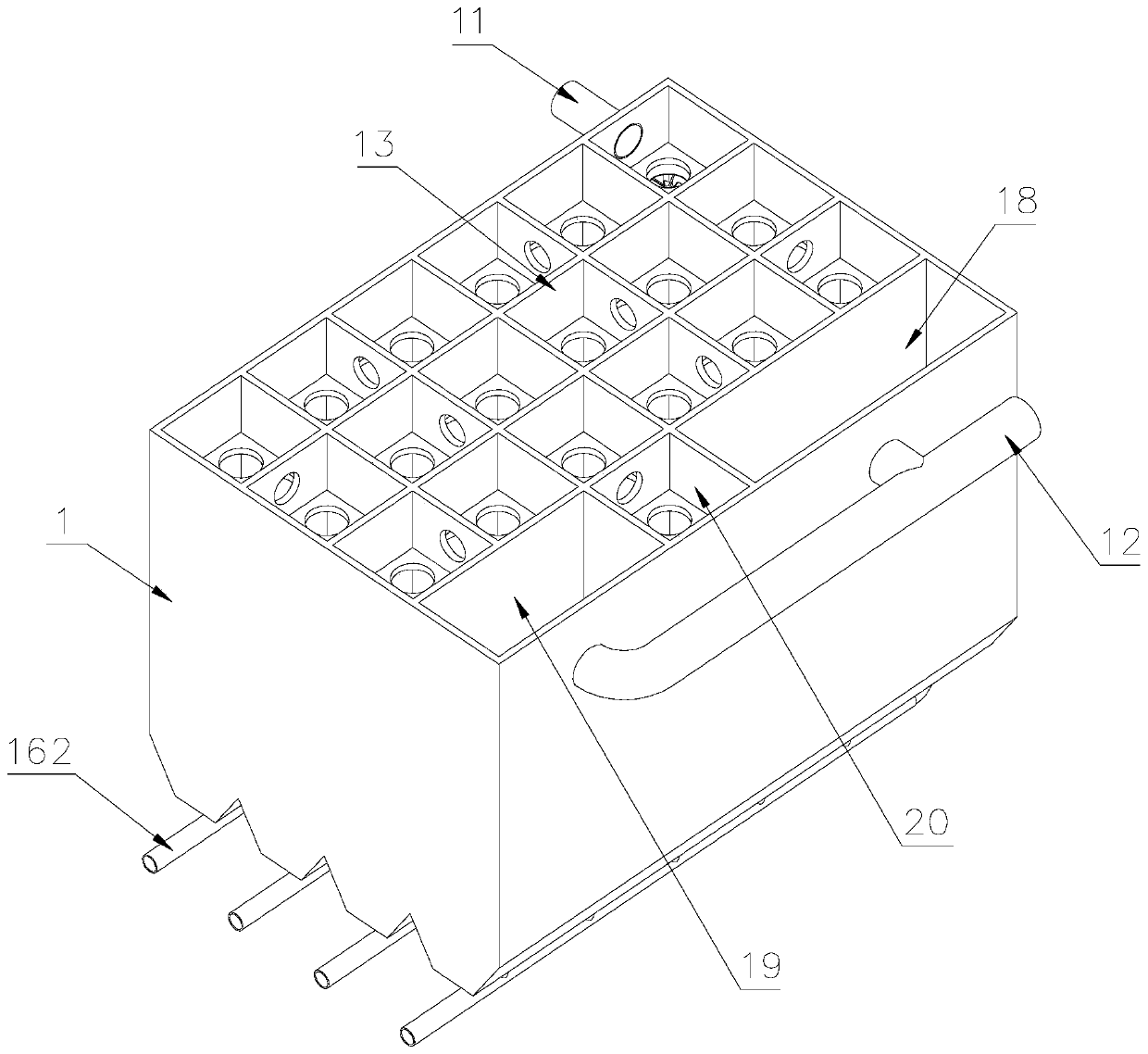

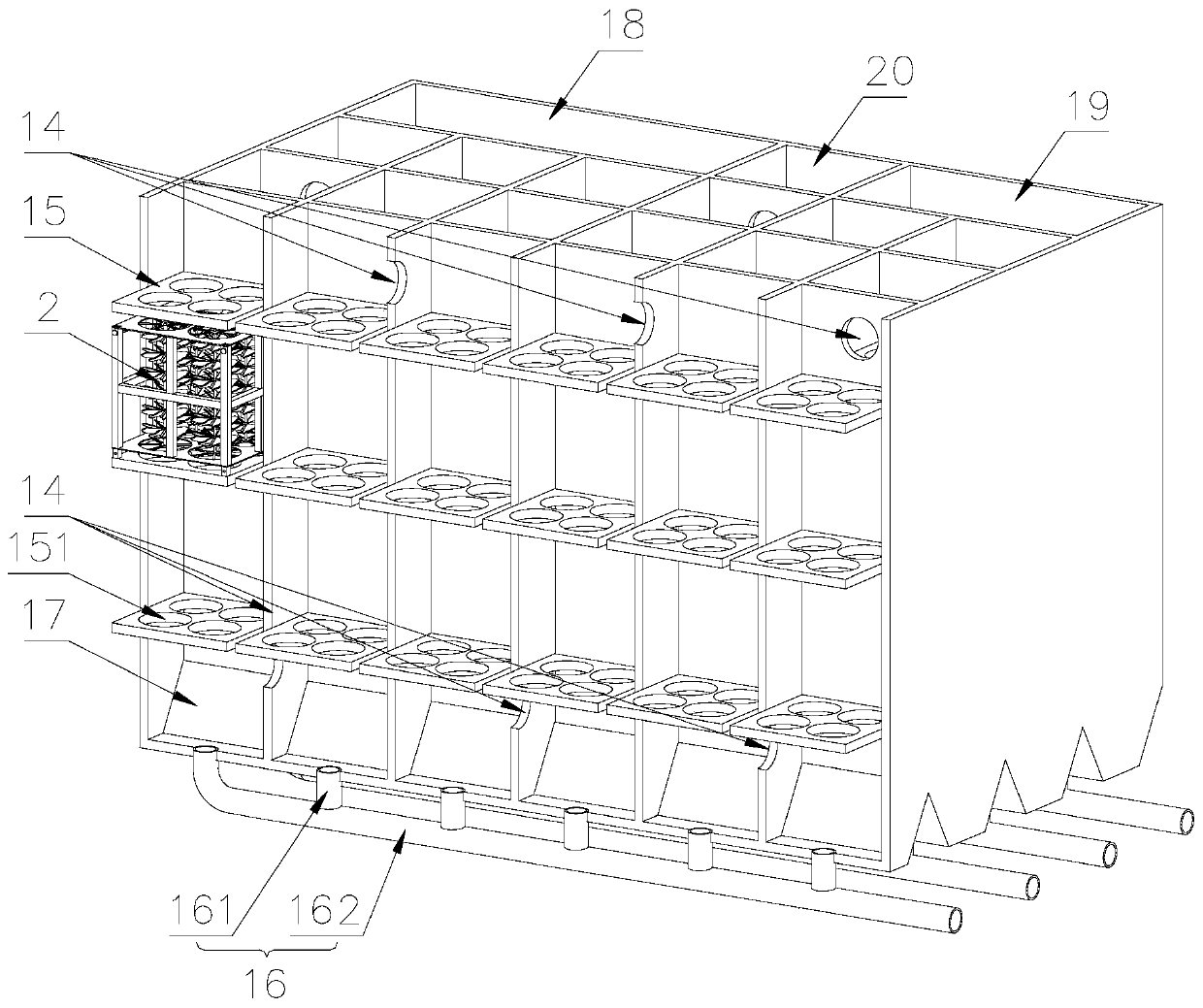

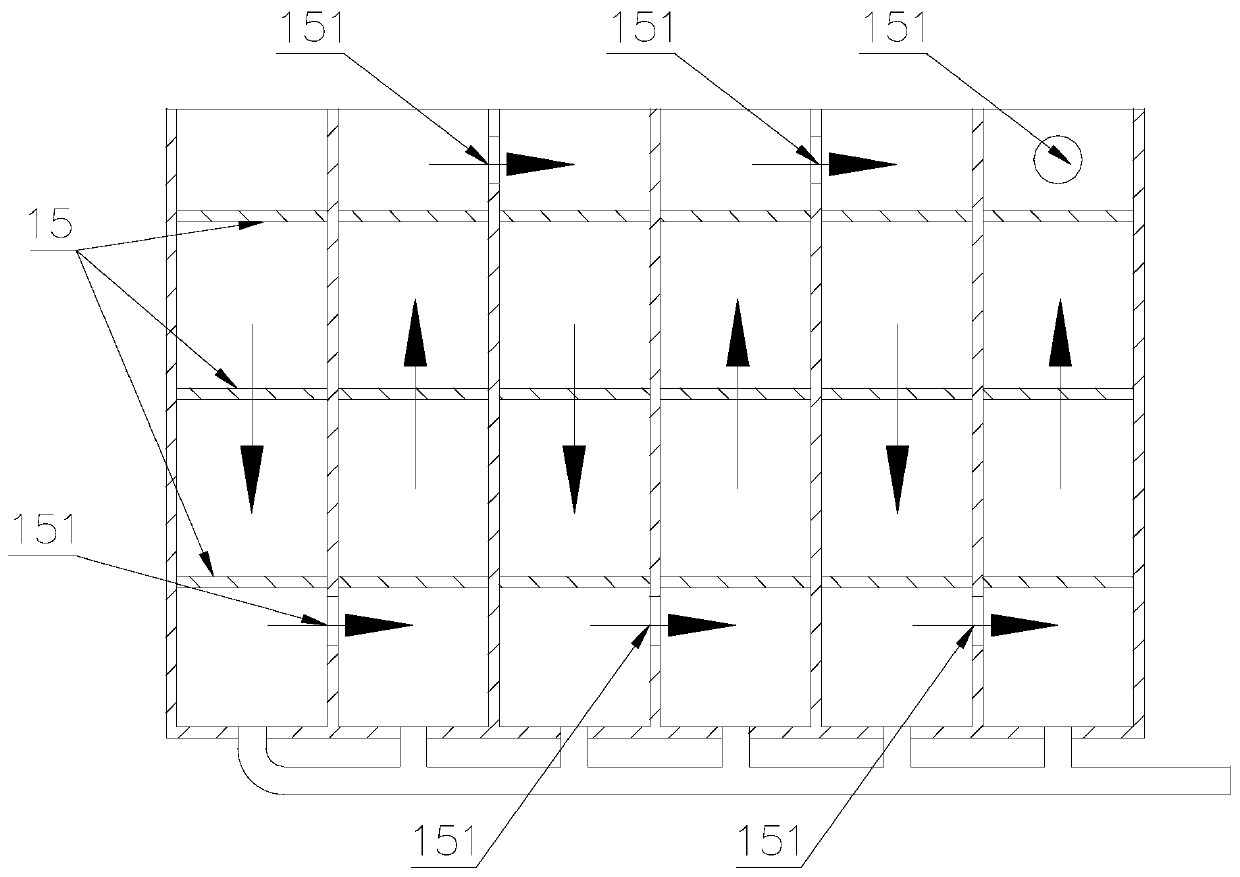

Grid flocculation basin based on fan blade structure filler

PendingCN111099707ACongeal fastShort passage timeWater/sewage treatment by flocculation/precipitationImpellerFlocculation

The invention discloses a grid flocculation basin based on a fan blade structure filler, a plurality of vertically staggered grid plates are arranged in a basin body, and water passing holes are formed in the adjacent grid plates in the same direction in a staggered manner; a plurality of filler frames are arranged in the flocculation grid; fan blade fillers are mounted at the upper parts of the filler frames; the fan blade filler comprises a support formed by connecting a plurality of square pipes, an upper pressing plate arranged at the upper end of the support and a lower pressing plate arranged at the lower end of the support, through holes are formed in the upper pressing plate and the lower pressing plate, a plurality of impellers are arranged on the pin, each impeller comprises an outer cylinder, a plurality of blades arranged on the outer cylinder and an inner cylinder arranged in the outer cylinder, and the inner cylinder is fixedly installed on the pin. The fan blade filler combination is regular, the flocculation passing time is short, water flow forms tiny vortex flow in the flocculation zone, flocculation equipment in a hydraulic stirring form is arranged into grids inthe flocculation zone, vortexes are increased, the colloid collision probability and the coagulation effect are improved, the turbulence vortex effect is enhanced, and the flocculation coagulation efficiency is improved.

Owner:SHANDONG WATER & WASTEWATER MONITORING CENT

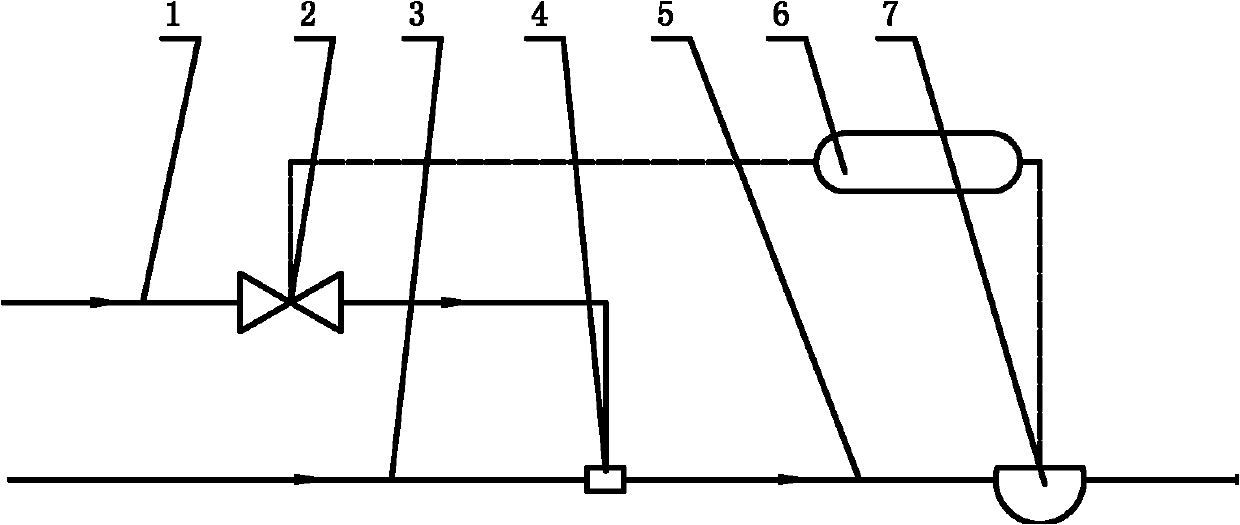

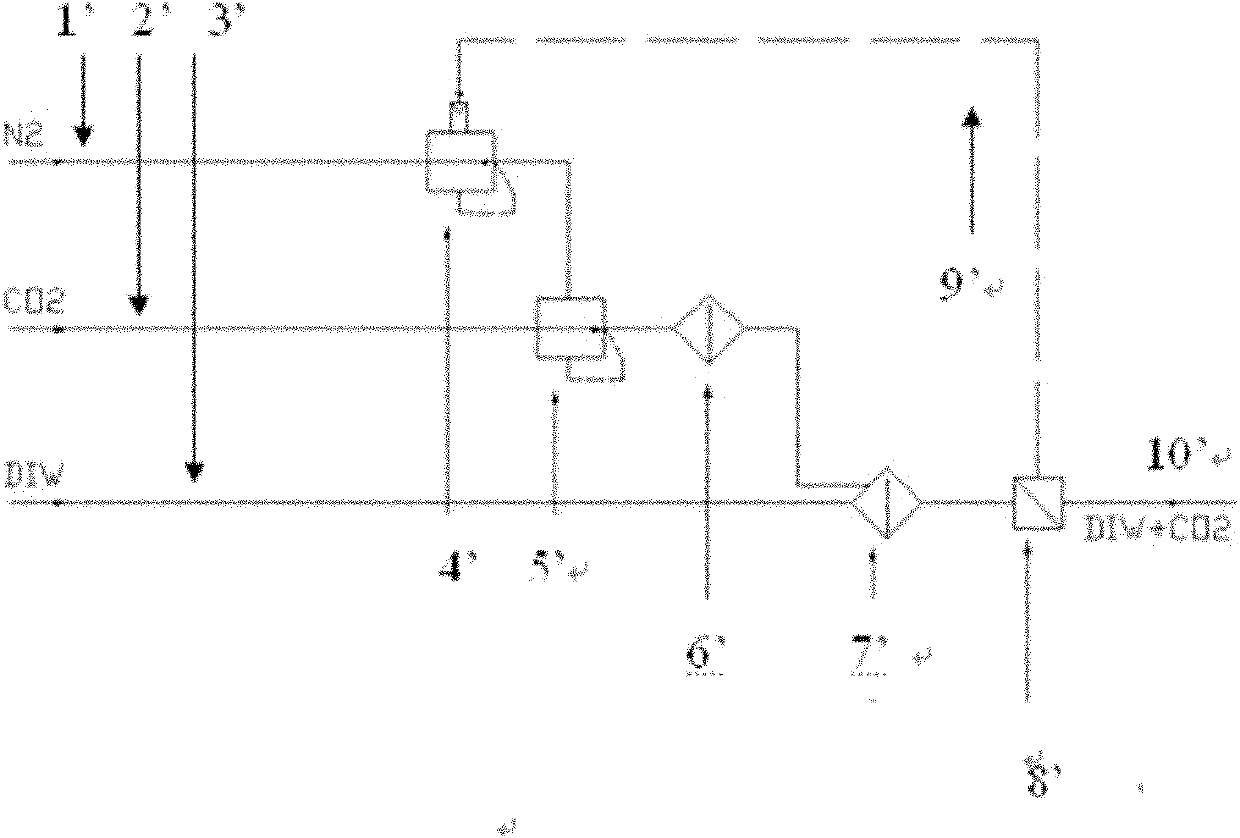

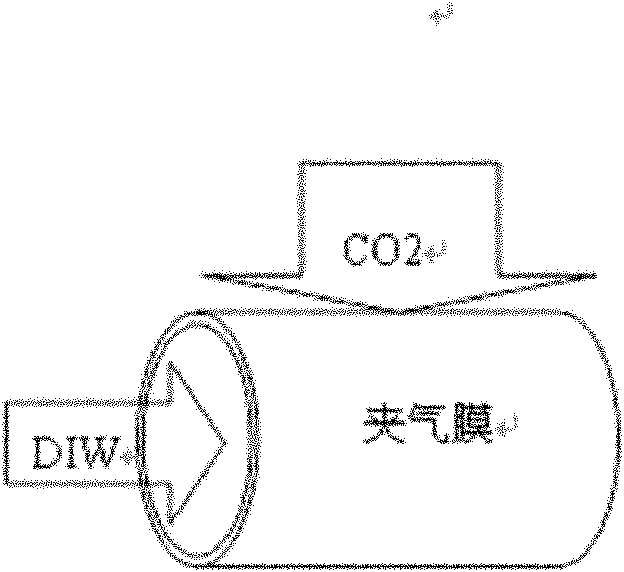

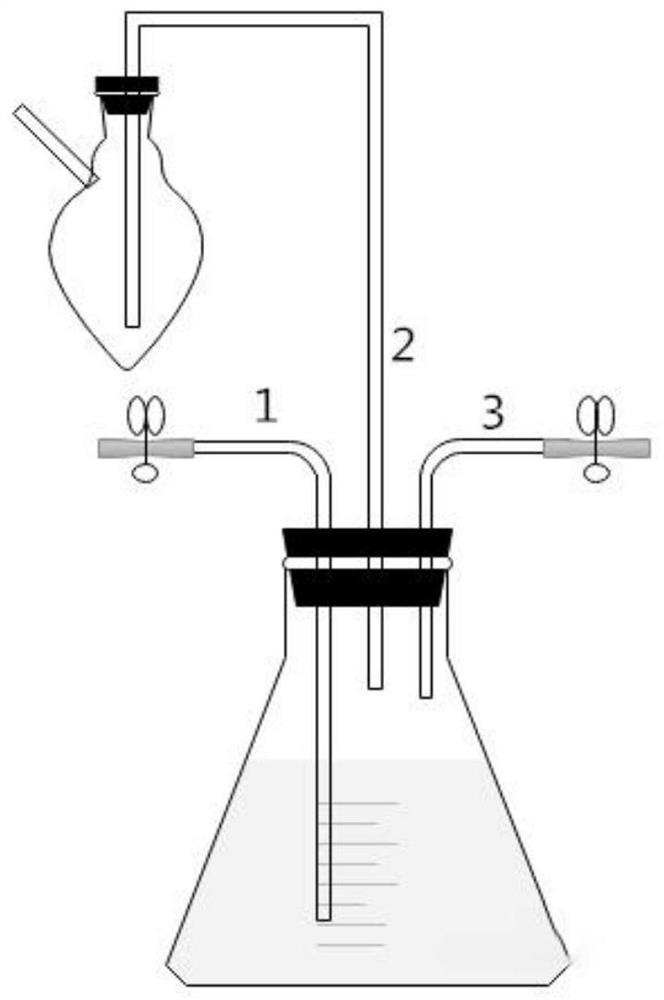

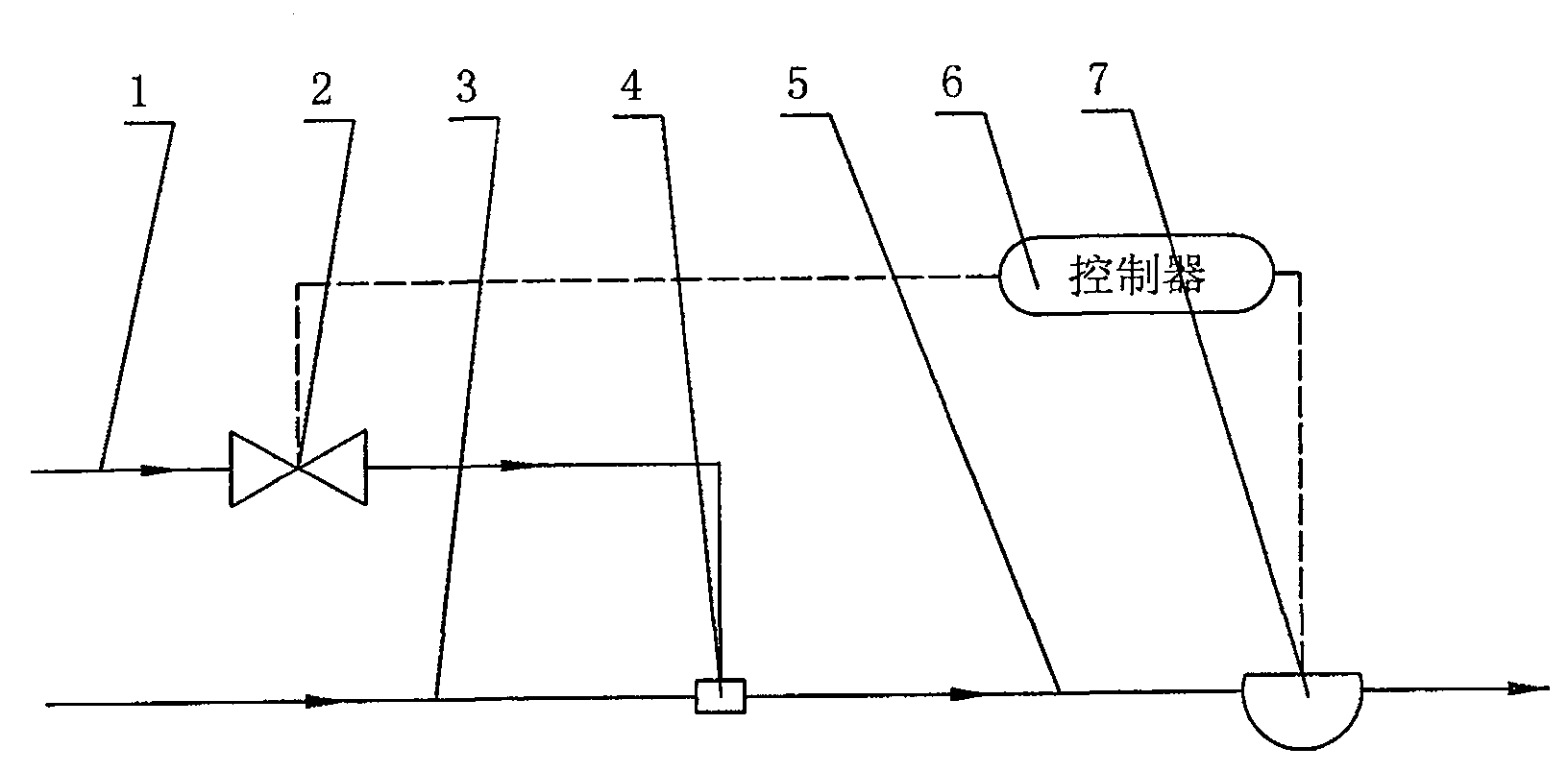

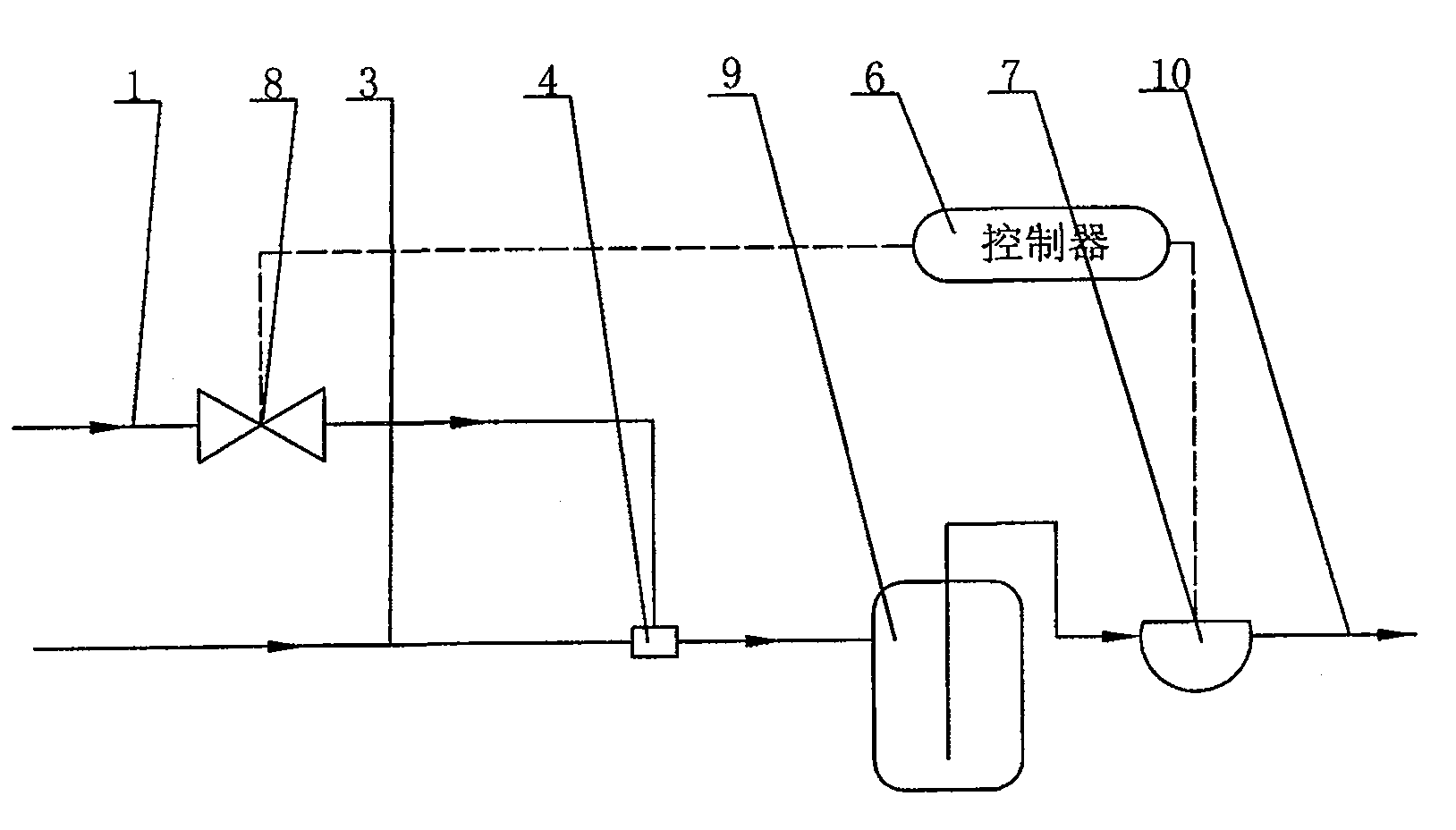

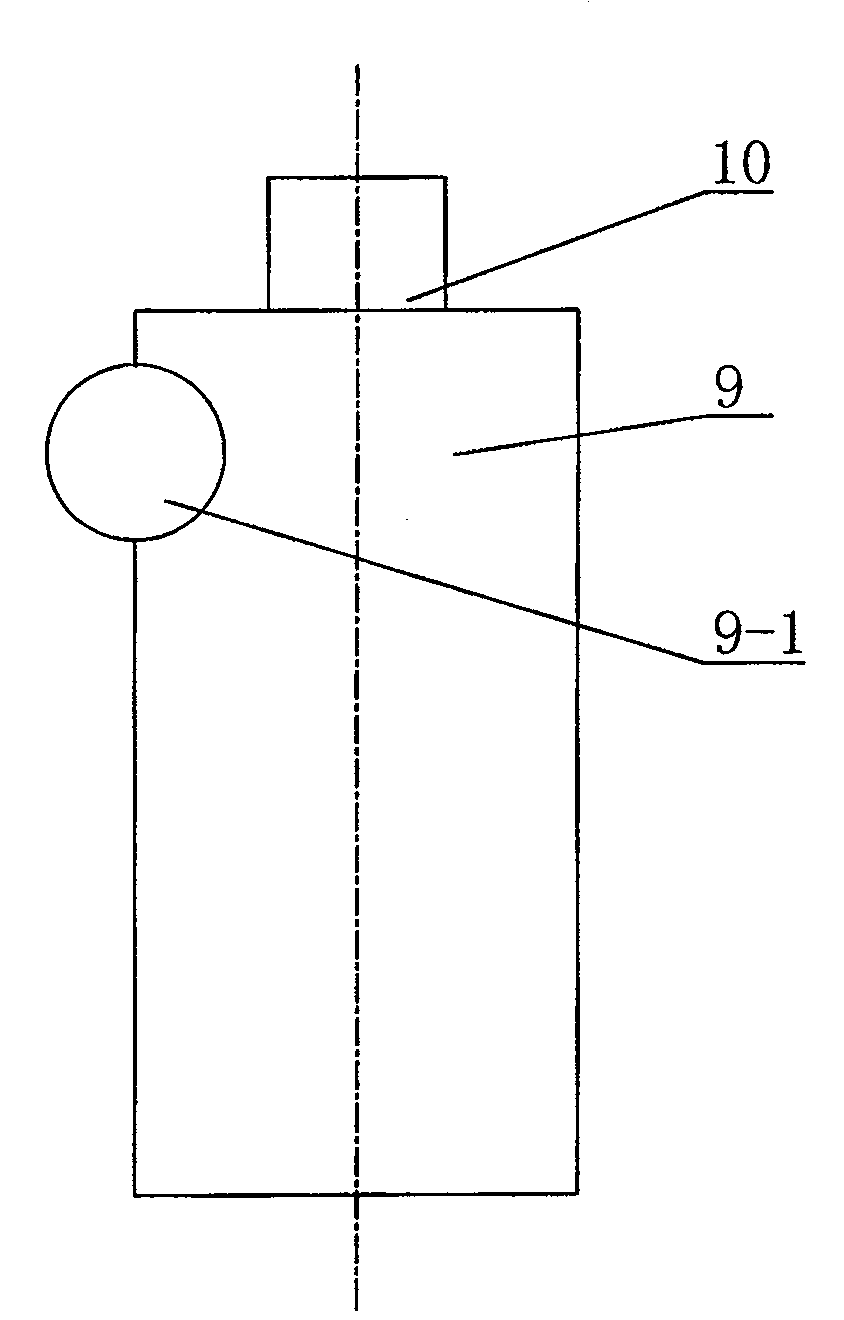

Method and device for preparing carbon dioxide ionized water

InactiveCN102166486AImprove solubilityIncrease contact areaFlow mixersMixing methodsWater dischargeProduct gas

The invention relates to the field of chip manufacturing and processing, particularly relates to a method for preparing carbon dioxide ionized water for cleaning chips as well as a generating device thereof. The invention aims to provide a method and device for preparing online carbon dioxide ionized water, which have the advantages of simple structure, and capability of increasing the dissolution ratio of carbon dioxide gas in deionized water and effectively improving the stability of ion concentration of the prepared ionized water. The method comprises the following steps: 1) feeding deionized water (DIW) and carbon dioxide (CO2) into a gas-liquid mixing cylinder to carry out complete mixing, wherein the gas-liquid mixing cylinder is provided with a clamping gas film; 2) carrying out ionic conductivity detection on the ionized water discharged from the gas-liquid mixing cylinder, thereby obtaining the conductivity value of the ionized water; 3) comparing the obtained conductivity value of the ionized water with a preset conductivity value, and adjusting a pressure-regulating valve by using a controller so as to control the inlet capacity of the carbon dioxide; and 4) obtaining ionized water with the preset conductivity value.

Owner:CHANGZHOU RUIZE MICROELECTRONICS

High-frequency multi-section pressurizing hot-pressing processing method

The invention provides a high-frequency multi-section pressurizing hot pressing processing method. The method comprises the following steps: 1, a mold is cleaned and materials are prepared, the materials are stacked, the stacked materials are pressed into a regular and compact entity, and residues on the mold are cleaned; 2, a release agent is applied and the mold is heated, namely the mold is heated, and the release agent is applied on the surface of the mold; 3, a plurality of hot presses with different pressures are prepared on the production line, the pressures of the hot presses are gradually increased from the first hot press to the last hot press, and the pressure of the last hot press is the same as the pressure of the hot press for single-time hot pressing; 4, the heated mold is fed into a production line and sequentially passes through hot presses with different pressures. 5, cooling and demolding are conducted, specifically, the mold passing through the last hot press is subjected to water cooling to 200 DEG C through a pipeline, and the mold cooled to 200 DEG C is subjected to demolding; and 6, machining forming is conducted, a demolded product is cleaned, and polishing is conducted after cleaning. The method has the advantage that the hot-pressing effect is improved.

Owner:海斯坦普汽车组件(天津)有限公司

Reduce evaporation loss of pt and rh at high temperature by applying isolation layer

InactiveCN103168008BReduce viscosityEfficient purificationForehearthsGlass furnace apparatusPlatinumAlloy

Parts made of platinum or a Pt alloy, the outer surface of which comes in contact with an oxidizing atmosphere during operation and is covered with an open-cell ceramic or quartz layer, the pores containing a material that melts at the operating temperature as an infiltration material, are protected against loss caused by evaporation when used in an oxidizing atmosphere at temperatures exceeding 1200°C. A method for reducing the evaporation rate out of platinum and Pt alloys in an oxidizing atmosphere comprises the steps of A. applying an open-cell quartz or ceramic layer, B. infiltrating said quartz or ceramic layer with a material melting at a lower temperature than the ceramic material such that pore spaces of the open-cell ceramic layer are partially or entirely filled by the infiltration material, C. use at temperatures exceeding 1200°C.

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

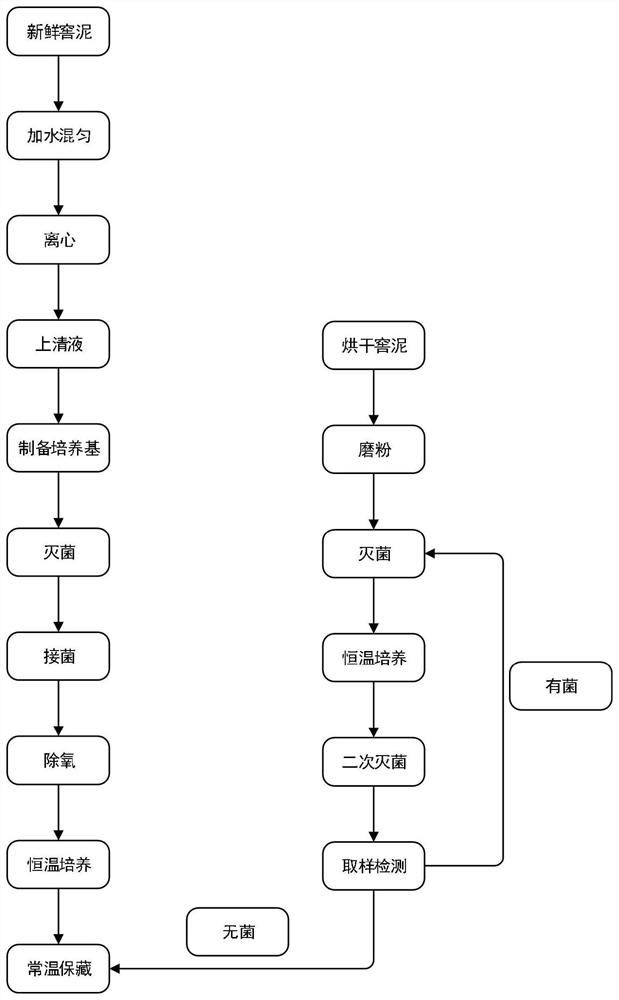

Normal Temperature Preservation Method of Caproic Acid Bacteria

ActiveCN111019832BExperiment operation is simpleShort passage timeBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention discloses a normal temperature preservation method of caproic acid bacteria. The purpose of the present invention is to improve the culture medium, add a protective agent, and use an oxygen scavenger to finally realize the normal temperature preservation of caproic acid bacteria. The strain preservation method provided by the present invention can be applied to those laboratories with basic anaerobic culture facilities. It has low requirements on technical equipment, small investment, mild storage conditions, and is suitable for use in laboratories.

Owner:HUBEI UNIV OF TECH

Method for culturing pig hair papilla cells

ActiveCN113061570APassaging Time SimplifiedShort passage timeCell dissociation methodsEpidermal cells/skin cellsPancreatinumCollagenase

The invention relates to a method for culturing pig hair papilla cells. The pig hair papilla cells are taken from pig ear skin tissues, I-type collagenase and pancreatin are used for digestion and separation, and a fetal calf serum culture medium is used for adding rat tail collagen for cell culture. By adopting the method provided by the invention, the epidermis and dermis structures are easy to distinguish, the hair follicle structure is clear and easy to separate, the cell passage time is shortened by about 13 hours, and the adherence is firmer. According to the method provided by the invention, the characteristics of the pig hair papilla cells can be kept within seven generations, and the purity is high, so that the pig hair papilla cells with high purity and relatively good passage consistency can be obtained in batches.

Owner:CHINA AGRI UNIV

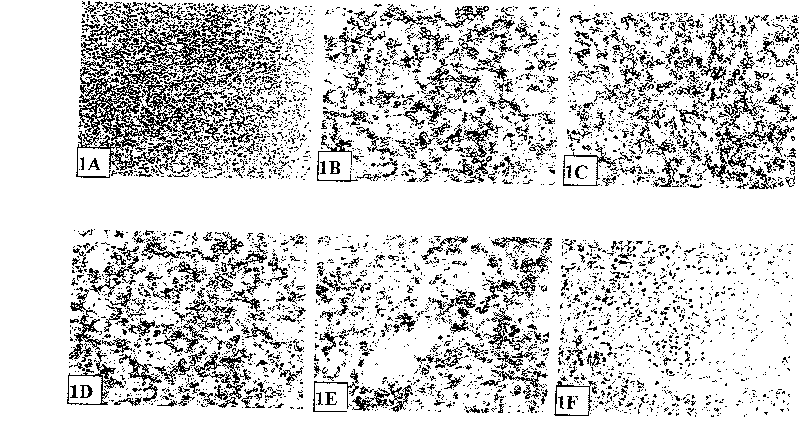

Method for establishing extranodal nasal type NK/T-celllymphoma animal model

InactiveCN1879892BAvoid missingStable growth cycleIn-vivo testing preparationsT lymphocyteNude mouse

The invention relates to a method for building the animal model of external nose shape NK / T lymphocyte cancer, which comprises: a, seeding, b, generating, c, checking, while it optimizes the parameters of each step, to overcome the defects of prestn technique. The invention has short generating time, with high on-time seeding success ratio. Compared with present technique, it can build the animalmodel of external nose shape NK / T lymphocyte cancer. And the model can replay the key biological character of external nose shape NK / T lymphocyte cancer, with stable growing period and wider application.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

A method for establishing a sheep endometrial epithelial cell line and its application

ActiveCN111808823BStable and continuous expressionEfficiently obtainedGenetically modified cellsTransferasesPiggybac transposonEndometrial epithelium

The invention belongs to the field of biotechnology, and in particular relates to a method and application for establishing a sheep endometrial epithelial cell line. The invention introduces the hTERT gene into the sheep endometrial epithelial cells through the PB transposition vector, realizes the immortalization of the cells, and provides a sheep endometrial epithelial cell line that is easy to culture, has a fast growth rate and a simple operation method and a method for establishing the same. . The PiggyBac transposon transgenic vector used in the present invention can be inserted into the "TTAA" site of the cell genome at a fixed point, which can effectively avoid the influence of genome epigenetic modification and position effect on the target gene, so that the target gene can be expressed stably and continuously. As a result, immortalized cells can be obtained more efficiently, and the physiological characteristics of the transfected cells and the primary cells are guaranteed to be closer.

Owner:SHIHEZI UNIVERSITY

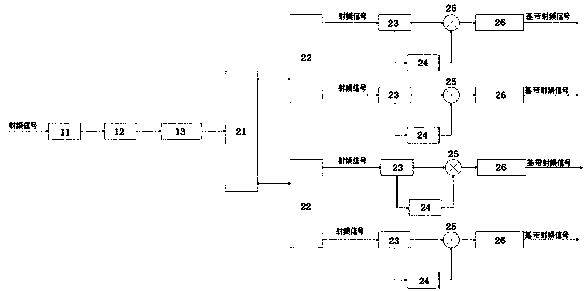

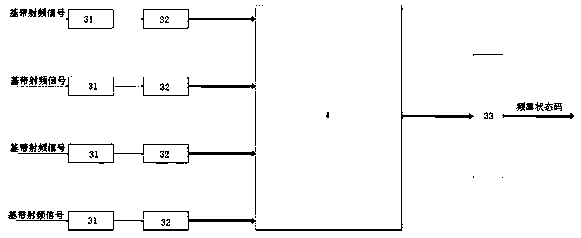

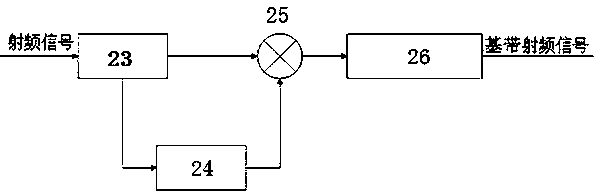

Microwave broadband instant frequency measurement receiving system

PendingCN108777599AReduce power consumptionImprove frequency measurement accuracyReceivers monitoringMicrowaveGate array

The invention relates to a microwave broadband instant frequency measurement receiving system, which comprises a radio frequency processing unit, a power distribution unit, a signal conversion unit and a programmable gate []array unit, wherein the ratio frequency processing unit is used for receiving radio frequency signals; the radiation frequency processing unit converts the input radio frequency signals into first baseband signals to be output; the power distribution unit is used for receiving the first baseband signals and allocates the signals to form at least two paths of second basebandsignals to be output; the signal conversion unit is used for receiving each path of second baseband signals in a one-to-one corresponding way; each second base band signal is converted to the presetfrequency and is then output; the programmable gate array unit is used for receiving each second baseband signal, and after []looking-up table operation, the programmable gate array unit outputs multipath parallel frequency state code or high-speed optical signals through a driver. The frequency measurement precision of the equipment is high; the EMS being smaller than 3 MHz can be reached; the size is small; the weight is light; the power consumption is low; the passing time is short; the operation is convenient.

Owner:上海频语电子技术有限公司

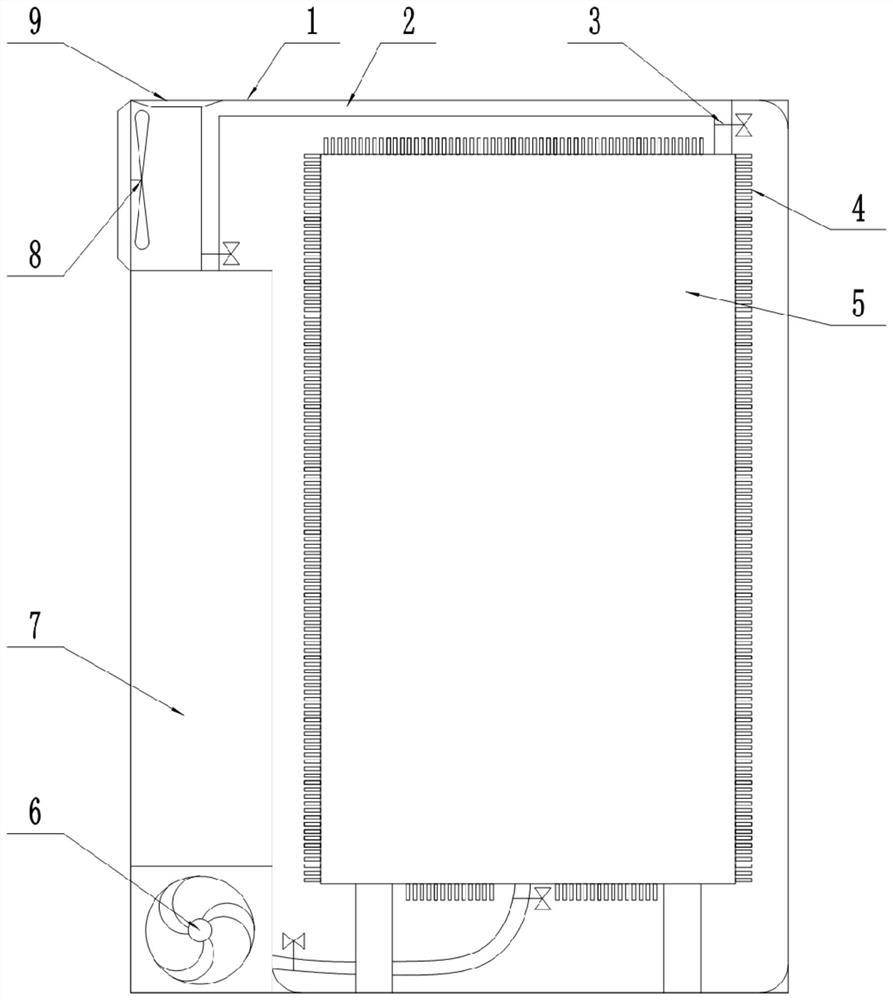

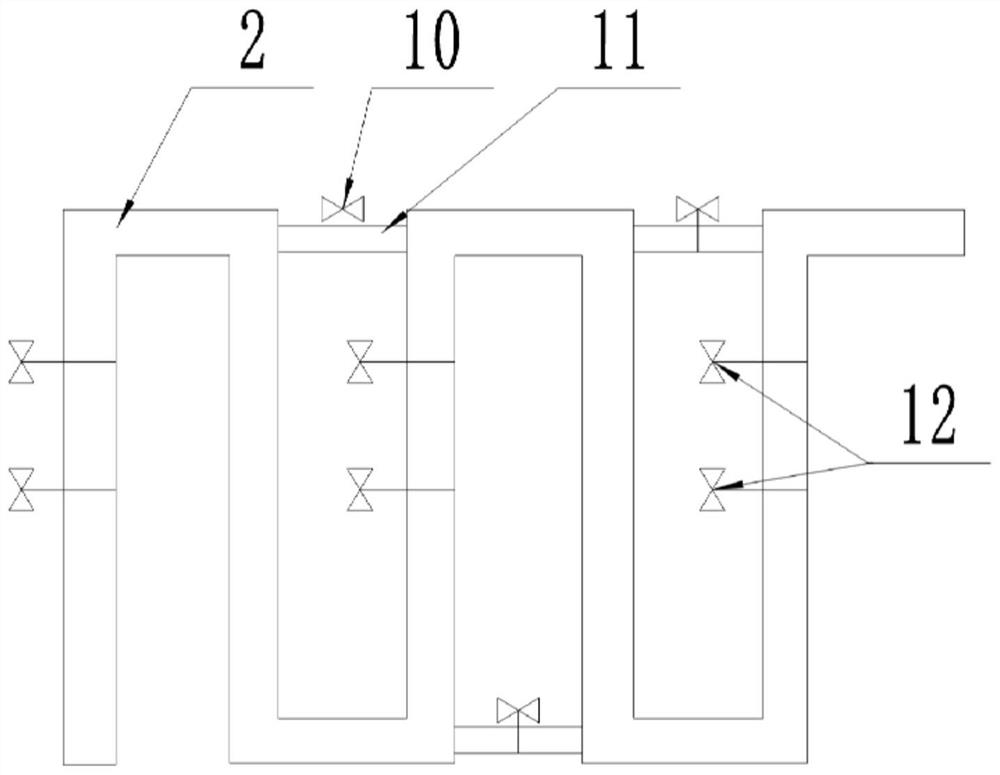

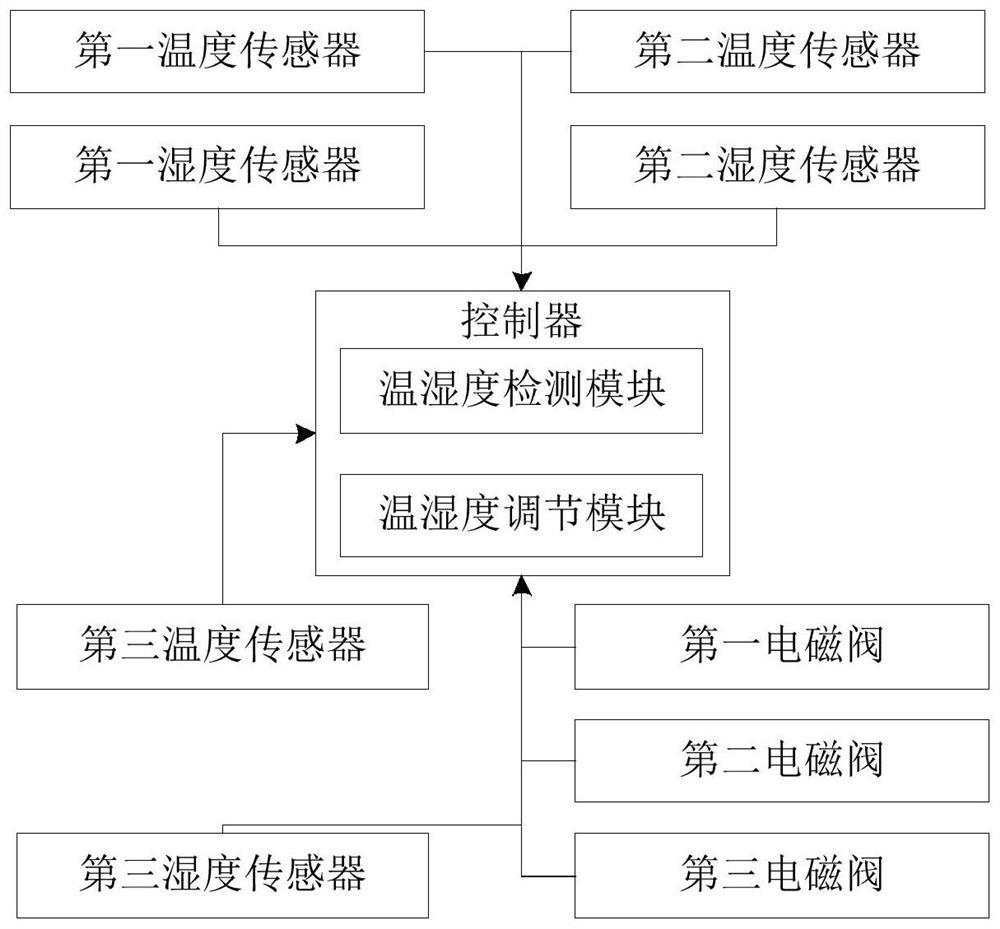

Automatic temperature and humidity adjusting system and method for ACU cabinet

PendingCN114667047AEasy to adjust temperature and humidityReduce the temperatureModifications using gaseous coolantsAir compressionEngineering

The invention relates to the technical field of intelligent cabinets, in particular to an automatic temperature and humidity adjusting system and method for an ACU cabinet, the system comprises an outer cabinet body, an inner cabinet body and a control assembly, the inner cabinet body is arranged in the outer cabinet body, and a circulating air duct and an air compression assembly are arranged between the inner cabinet body and the outer cabinet body; an air storage box is arranged in the circulating air duct; the air compression assembly comprises air compression equipment, a first air compression pipeline and a second air compression pipeline; one end of the first air compression pipeline is connected with air compression equipment, and the other end is connected with the inner cabinet body; the air compression equipment is connected with the air storage box; one end of the second air compression pipeline is connected with the air storage box, and the other end is connected with the inner cabinet body; the control assembly comprises a temperature and humidity detection module and a temperature and humidity adjusting module, the temperature and humidity in the ACU cabinet can be automatically adjusted, and normal work of the ACU area control module is prevented from being affected.

Owner:中煤科工集团重庆智慧城市科技研究院有限公司 +1

Temperature field adjustable type high efficiency burnt gas pulsating combusting device

InactiveCN101334216BShort passage timeIncrease the heat exchange areaWater heatersGaseous fuel burnerCombustorCombustion chamber

The invention relates to a highly efficient fuel gas pulsating combustor with an adjustable temperature field, which is composed of fuel gas inlet pipes, air inlet pipes, a combustion chamber, a heat releasing chamber and a furnace pipe, wherein, at least a group of fuel gas inlet pipes and air inlet pipes are arranged and connected at intervals at a tubular end of the combustion chamber, the other end of the combustion chamber is connected with the heat releasing chamber, and a plurality of branch furnace pipes are radially connected on an arc shaped end socket of the outlet of the heat releasing chamber. The diameter of the cylinder of the heat releasing chamber connected with the combustion chamber is larger than that of the combustion chamber, at least one flow flexing plate is radially arranged inside the heat releasing chamber, and isomorphic or heterogeneous pore passages are arranged on each flow flexing plate. The highly efficient fuel gas pulsating combustor with the adjustable temperature field of the invention has the advantages of high combustion efficiency, combustion intensity and heat exchange performance, low pollutant content in the discharged flue gas, long service life and improved working efficiency.

Owner:大庆石油化工机械厂有限公司

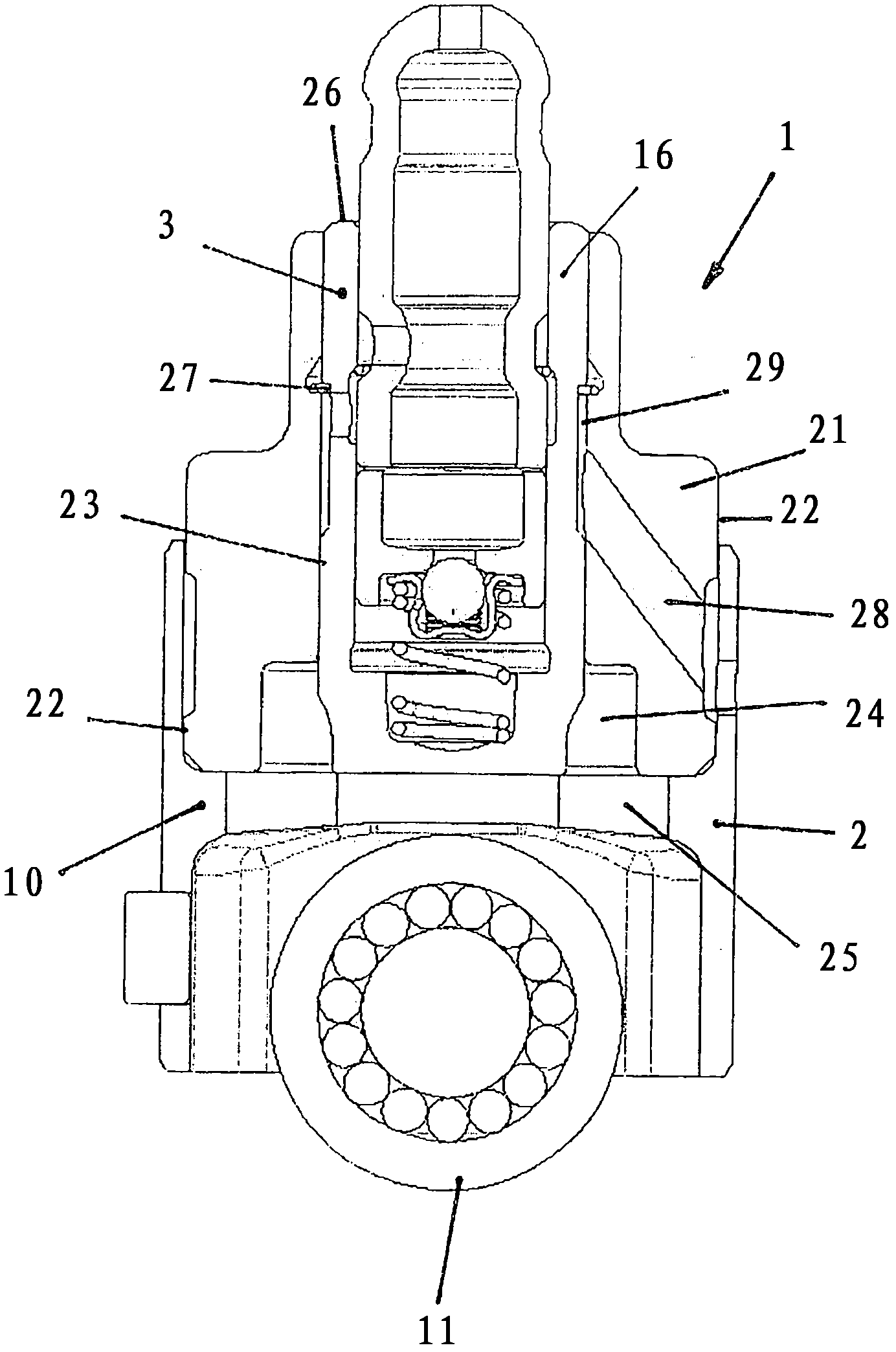

Roller Cam Followers

InactiveCN102588026BGuaranteed unchangedImprove the lubrication effectValve arrangementsMachines/enginesExternal combustion engineEngineering

The roller cam follower (1) comprises a hydraulic support unit (3) and a down or lateral cam shaft of an internal combustion engine. The roller cam follower is assembled from a roller shaft (2) for the stroke operation of a piston of a fuel high pressure pump and the hydraulic support unit. An independent claim is also included for a roller shaft has a support unit which is received in sections in a recess.

Owner:SCHAEFFLER TECH AG & CO KG

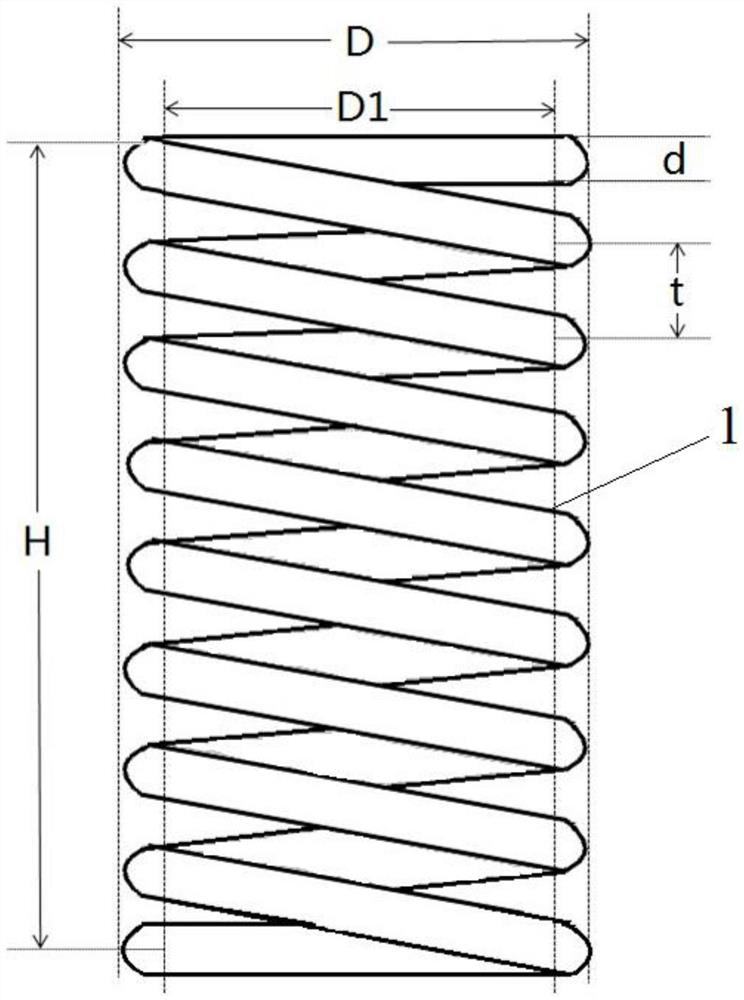

Passage method of pluripotent stem cells

ActiveCN114807018AHigh activityGuaranteed not to be brokenCell dissociation methodsGenetically modified cellsCell-Extracellular MatrixEngineering

The invention discloses a passage method of pluripotent stem cells. The method comprises a passage tool and a prepared dissociation liquid, the passage tool comprises a precision spring, a rolling shaft and tweezers, the precision spring sleeves the rolling shaft, a clamping groove is formed in the surface of the rolling shaft and can be fixed to the tip end of the tweezers, the distance between spring wires is adjusted by compressing the spring, the assembly can be used for passage of the pluripotent stem cells after being sterilized, and the tweezers are held to push and roll the precision spring during passage. The method comprises the following steps: cutting pluripotent stem cell colonies by using a precise spring wire, cutting the pluripotent stem cell colonies into small pieces with uniform sizes, and then adding dissociation liquid to enable the cut pluripotent stem cell pieces to be easily eluted and collected by pipetting, thereby completing the passage amplification of the pluripotent stem cells. The method is simple, reliable, universal, easy to implement and low in cost, integrates various advantages of an existing method, does not need digestion of an enzyme and a calcium ion chelating agent, does not damage an extracellular matrix of the pluripotent stem cells, and can efficiently carry out pluripotent stem cell passage.

Owner:深圳市旷逸生物科技有限公司

Establishment method and application of sheep endometrial epithelial cell line

ActiveCN111808823AStable and continuous expressionEfficient expressionGenetically modified cellsTransferasesPiggybac transposonTransgene

The invention belongs to the technical field of biology, and particularly relates to an establishment method and application of a sheep endometrial epithelial cell line. An hTERT gene is introduced into the sheep endometrial epithelial cells through a PB transposon vector, immortalization of the cells is achieved, and the sheep endometrial epithelial cell line which is easy to culture, high in growth speed and easy and convenient to operate and the establishment method of the cell line are provided. The PiggyBac transposon transgenic vector used in the invention can be inserted into a TTAA locus of a cell genome at a fixed point, so the influences of genome epigenetic modification and a position effect on a target gene can be effectively avoided, and the target gene can be stably and continuously expressed. Thus, immortalized cells can be obtained more efficiently, and the invention guarantees that the physiological characteristics of the transfected cells are closer to those of primary cells.

Owner:SHIHEZI UNIVERSITY

Method and device for on-line production of carbon dioxide ion water

ActiveCN100563804CImprove solubilityFast dissolutionReversed direction vortexFlow mixersWater flowProduct gas

The invention relates to a method and device for preparing carbon dioxide ionized water on-line. Carbon dioxide gas is mixed with deionized water in a three-way pipe after passing through a pressure regulating valve, and then enters a mixing cylinder along a tangential direction, and the mixture is in the mixing chamber of the mixing cylinder A spiral vortex is formed, the bubbles in the mixture are broken up under the action of centrifugal force, the carbon dioxide gas is dissolved into the deionized water to form ionized water, the ionized water flows out through the outlet pipe, the conductivity probe detects the conductivity of the ionized water, and the The data is input into the controller and compared with the set conductivity, the controller outputs an adjustment signal according to the difference between the two conductivity, adjusts the opening of the pressure regulating valve, adjusts the pressure of carbon dioxide gas, and controls the ion concentration in the ionized water. The invention has a simple structure, and the carbon dioxide gas is fully dissolved under the vortex action in the mixing cylinder, which can greatly improve and control the concentration of carbon dioxide in the prepared ion water.

Owner:CHANGZHOU RUIKE MICRO ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com