Roller cam follower

A technology of roller cams and moving parts, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as cost, and achieve the effects of reducing grinding work, fast passing time, and economical manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

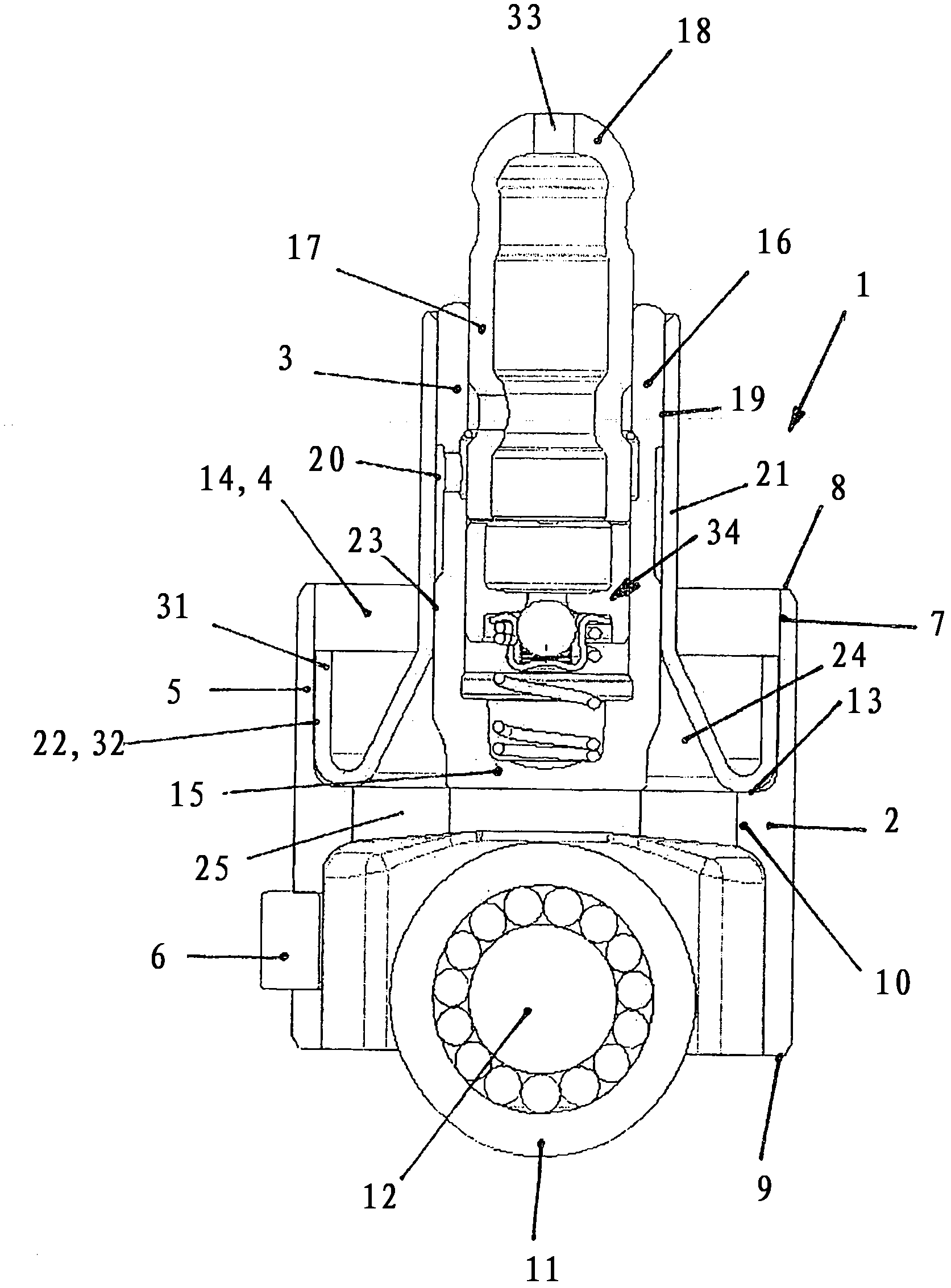

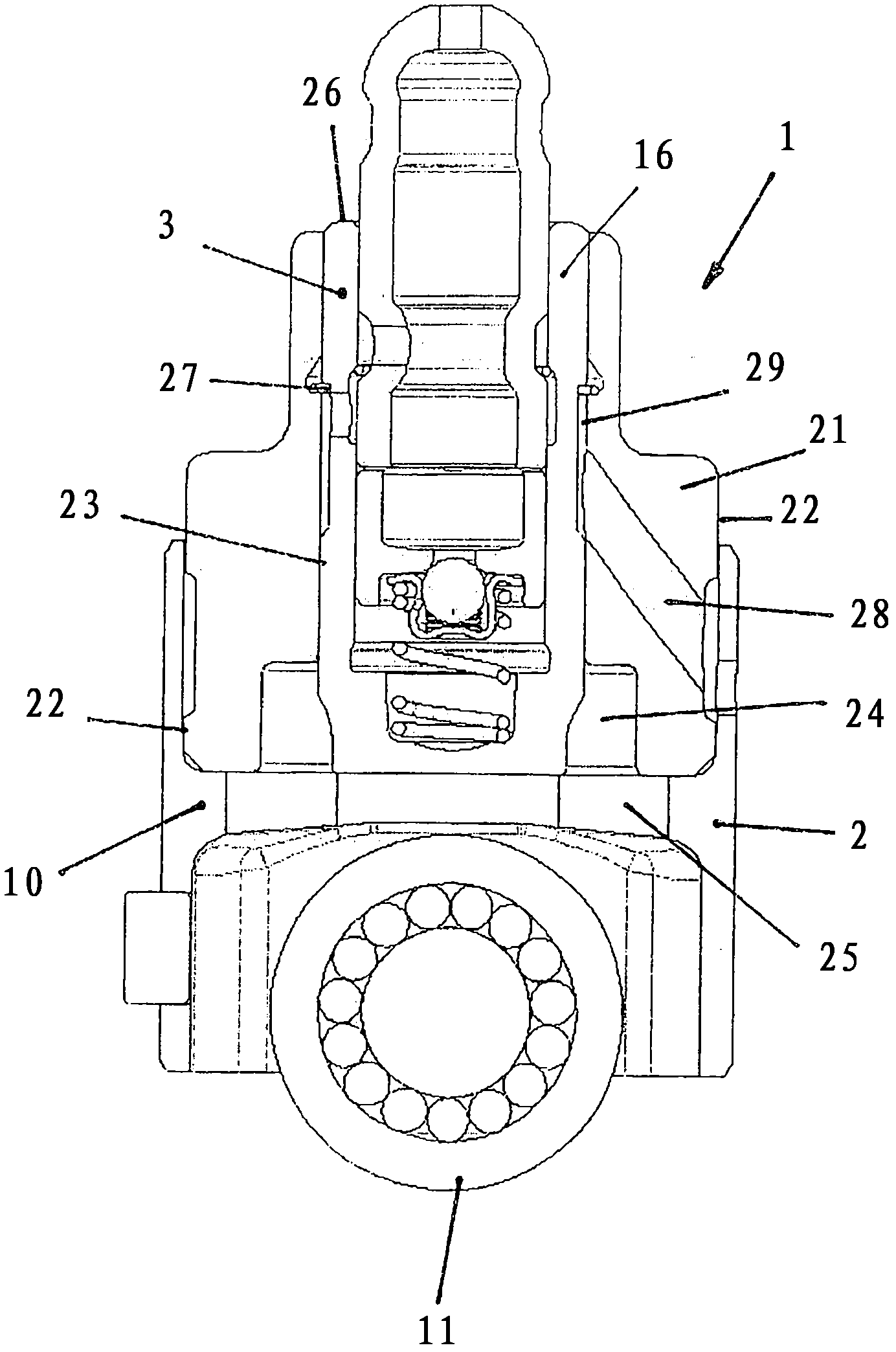

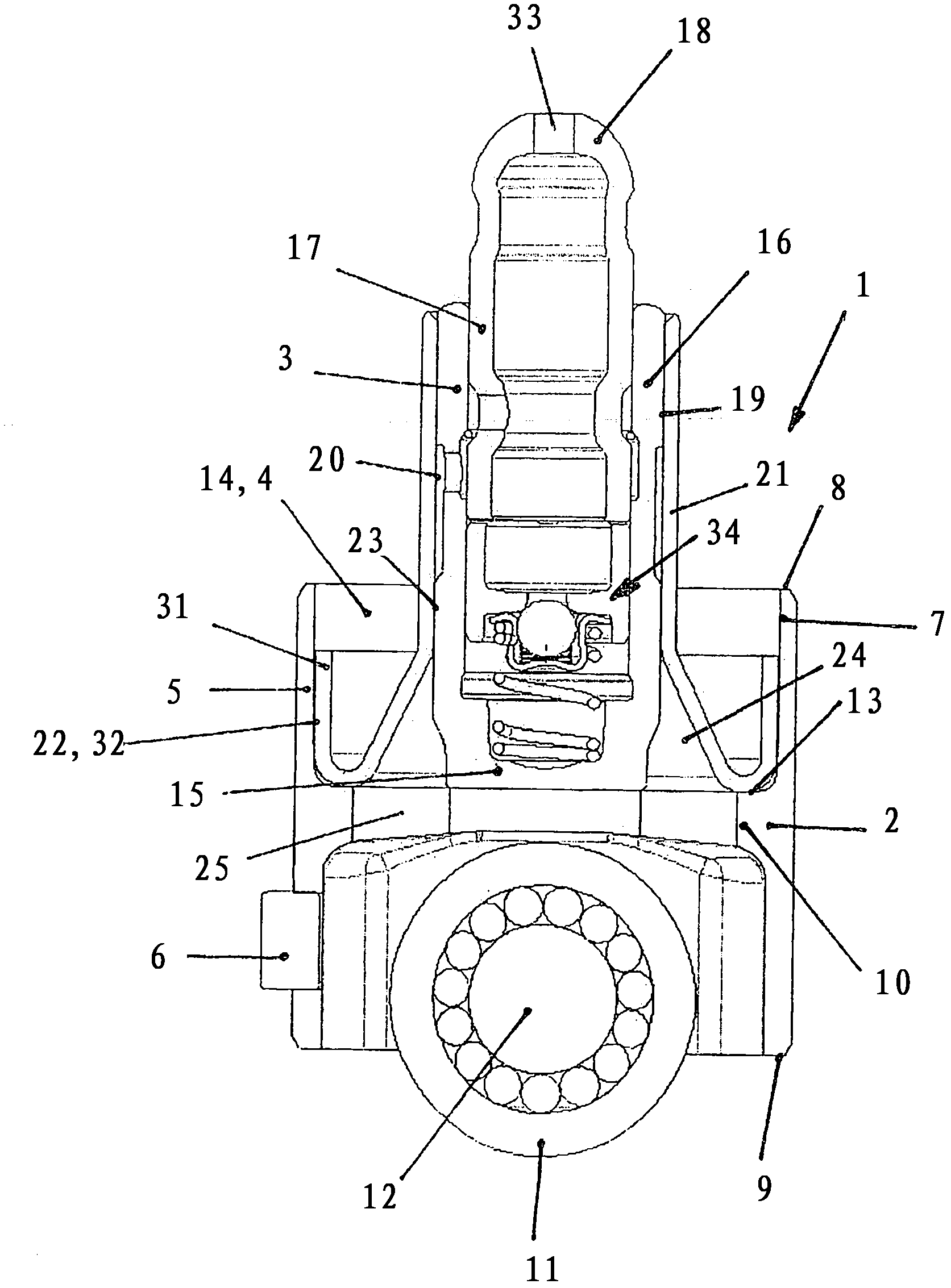

[0017] The figure shows the roller cam follower 1. The roller cam follower is used to reciprocate the rocker arm in the overhead valve mechanism with the camshaft located below. The roller cam follower is composed of a roller tappet 2 for reciprocating a piston of a high-pressure fuel pump and a hydraulic supporting element 3. The support element 3 here sits in the recess 4 of the roller tappet 2 formed by the upper side 13 of the bridge section 10 and the inner peripheral surface 7 of the housing 5. The adapter ring 21 serves as a connecting element.

[0018] The roller tappet 2 has a cylindrical casing 5 with a protruding anti-rotation fixing structure 6 which is here as a pin. The inner peripheral surface 7 of the casing is spaced apart from the edges 8, 9 of the casing 5, and is spanned by a bridging section 10 at approximately half the height (durchragen), and a cam roller 11 is provided below the bridging section, so The cam roller is supported on a pin 12 installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com