Dental pulp stem cell separation and culture method

A technology of dental pulp stem cells and culturing methods, which is applied to animal cells, vertebrate cells, bone/connective tissue cells, etc., can solve the problem of low total number of dental pulp stem cells, long passage of primary cells, and low viability of passaged cells, etc. problems, to achieve the effect of shortening the passage time, speeding up the growth, and improving the cell viability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

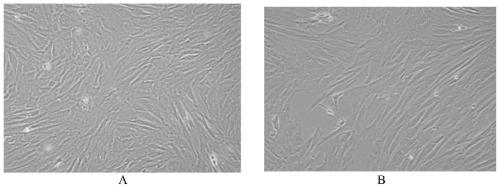

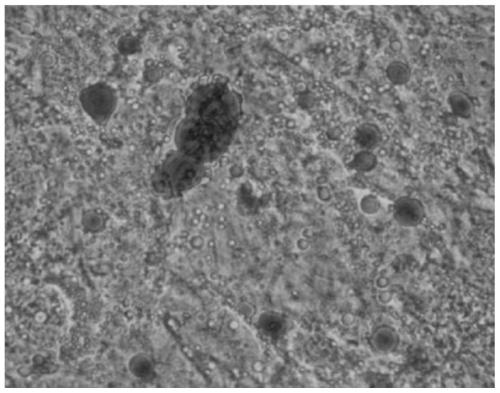

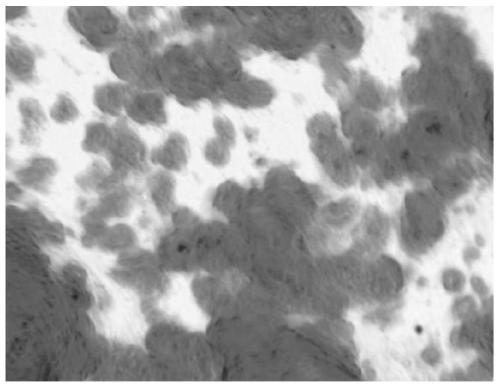

[0028] (1) Extraction of dental pulp tissue: Healthy white rabbits were selected as experimental subjects, male and female were randomly selected, and the age of the rabbits was 6 months. A molar was extracted from a white rabbit under local anesthesia, transferred to pre-cooled high-concentration double-antibody (double-antibody: streptomycin and penicillin), soaked for 10 minutes, disinfected, rinsed with PBS solution for 3 times, and then broken. Dental crown, extract the pulp from the pulp cavity of the tooth sample, and cut the pulp tissue into 0.4×0.4mm blocks.

[0029] (2) Put 2 times the volume of mixed enzyme in the above-mentioned dental pulp tissue for enzymatic hydrolysis; the mixed enzyme is a mixed solution of type IV collagenase, type V collagenase and trypsin with a mass volume concentration of 0.05% ; Digest for 4 hours at 37°C until the pulp tissue is completely digested, then centrifuge at 200 rpm for 5 minutes to remove the supernatant, and obtain enzymatic...

Embodiment 2

[0035] The only difference between this example and Example 1 is that in step (2), 10 times the volume of mixed enzyme is added to the cleaned pulp tissue.

Embodiment 3

[0037] The only difference between this example and Example 1 is that in the step (2), 20 times the volume of the mixed enzyme is added to the cleaned pulp tissue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com