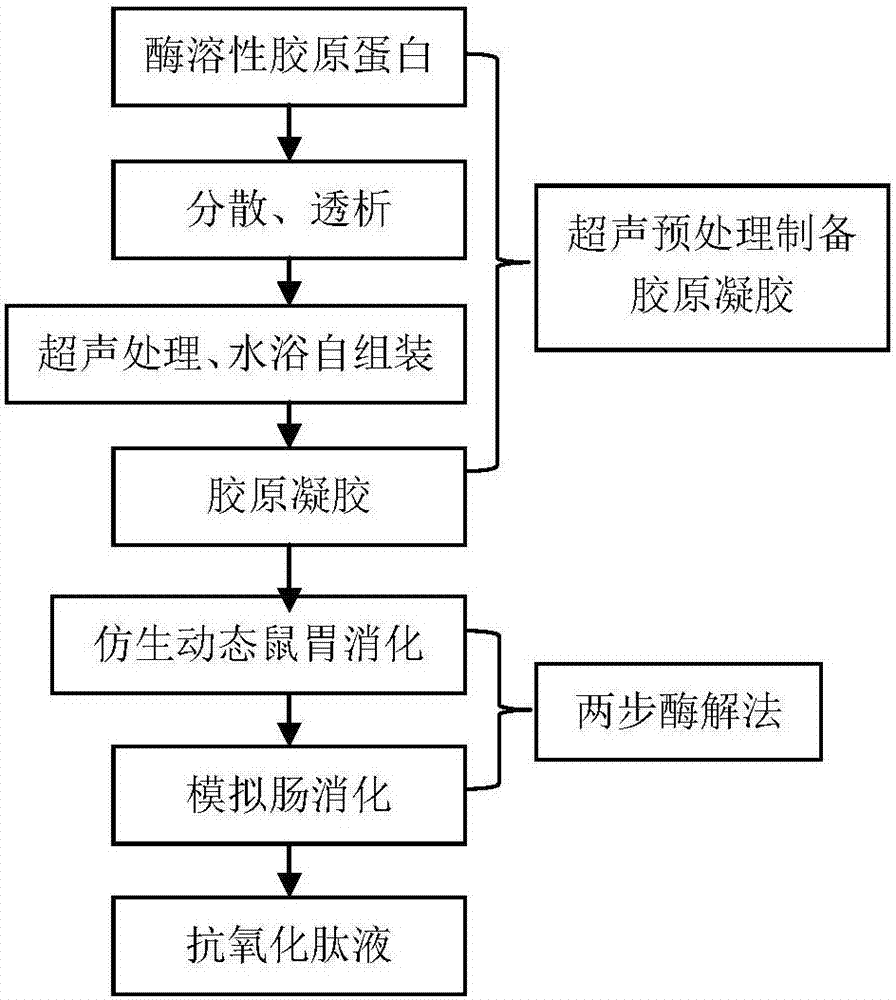

Method for preparing antioxidative peptide liquid of collagen gel with combination of ultrasonic treatment and simulative digestion

A collagen gel and antioxidant peptide technology, applied in the field of food processing technology and protein utilization, can solve the problems of incomplete enzymatic hydrolysis, complicated separation and purification, complex molecular weight distribution of polypeptides, etc., and achieve the effect of thorough digestion and favorable enzymatic digestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

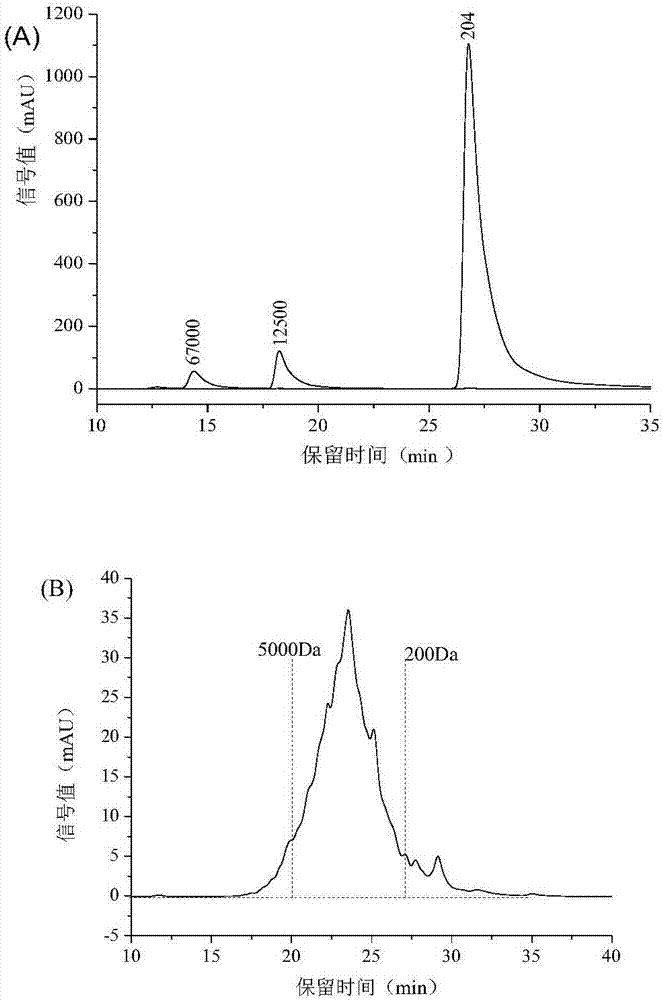

[0034]Weigh 0.04g enzymatically soluble collagen (collagen is prepared by the laboratory, chicken feet skin is removed by a solution of 20% (w / v) NaCl (0.05mol / L Tris-HCl, pH7.5) at 4°C Impurities such as miscellaneous proteins, fats and pigments. Pretreated chicken paw skin is extracted with precooled 0.5M acetic acid containing 0.1% (w / v) pepsin (2500U / mg), centrifuged, and the supernatant salting out gained precipitation is vacuum Freeze-drying is enzyme-soluble collagen.), with 0.5M acetic acid, prepared into a 0.02g / mL collagen solution, and dialyzed against phosphate buffer (200mM, pH7.4) in a refrigerator at 4°C. After the dialysis, the solution was centrifuged at 20000×g for 15 min, and the supernatant was taken. In a water bath at 30°C, use a single-frequency ultrasonic device at 270W / 60kHz for 5 minutes, and heat in a water bath at 30°C for 55 minutes to form collagen molecules and self-assemble to form a collagen gel. The collagen gel sponge was obtained by vacuum ...

example 2

[0037] Weigh 0.04g of enzyme-soluble collagen (made in the laboratory, same as Example 1), prepare 0.02g / mL collagen solution with 0.5M acetic acid, and dialyze against phosphate buffered saline (200mM, pH7.4) at 4°C . After the dialysis, the solution was centrifuged at 20000×g for 15 min, and the supernatant was taken. In a water bath at 30°C, use a single-frequency ultrasonic device at 270W / 60kHz for 5 minutes, and heat in a water bath at 30°C for 55 minutes to form collagen molecules and self-assemble to form a collagen gel. The collagen gel sponge was obtained by vacuum freeze-drying, which was used in the next step.

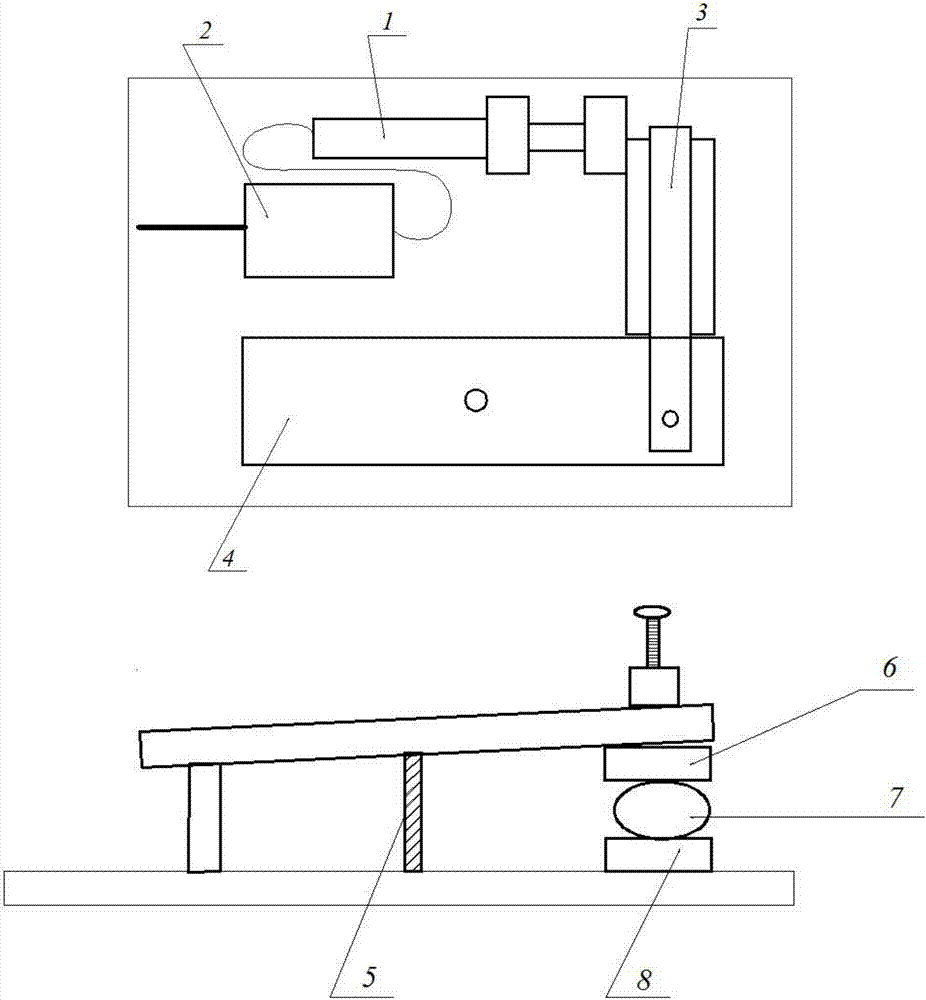

[0038] In the test, 2 mL of 0.02 g / mL collagen gel solution was prepared with distilled water to simulate gastrointestinal digestion in vitro. The bionic dynamic mouse stomach digestion system is set with an external electric compression device, which is adjusted by the motor to be close to the real mouse stomach peristaltic contraction frequency, that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com