Temperature field adjustable type high efficiency burnt gas pulsating combusting device

A pulsating combustion and adjustable technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems such as the failure of the pulsating combustion heating furnace, the failure of the tail pipe of the pulsating burner, and the uneven surface temperature distribution. Long service life, high heat exchange performance, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

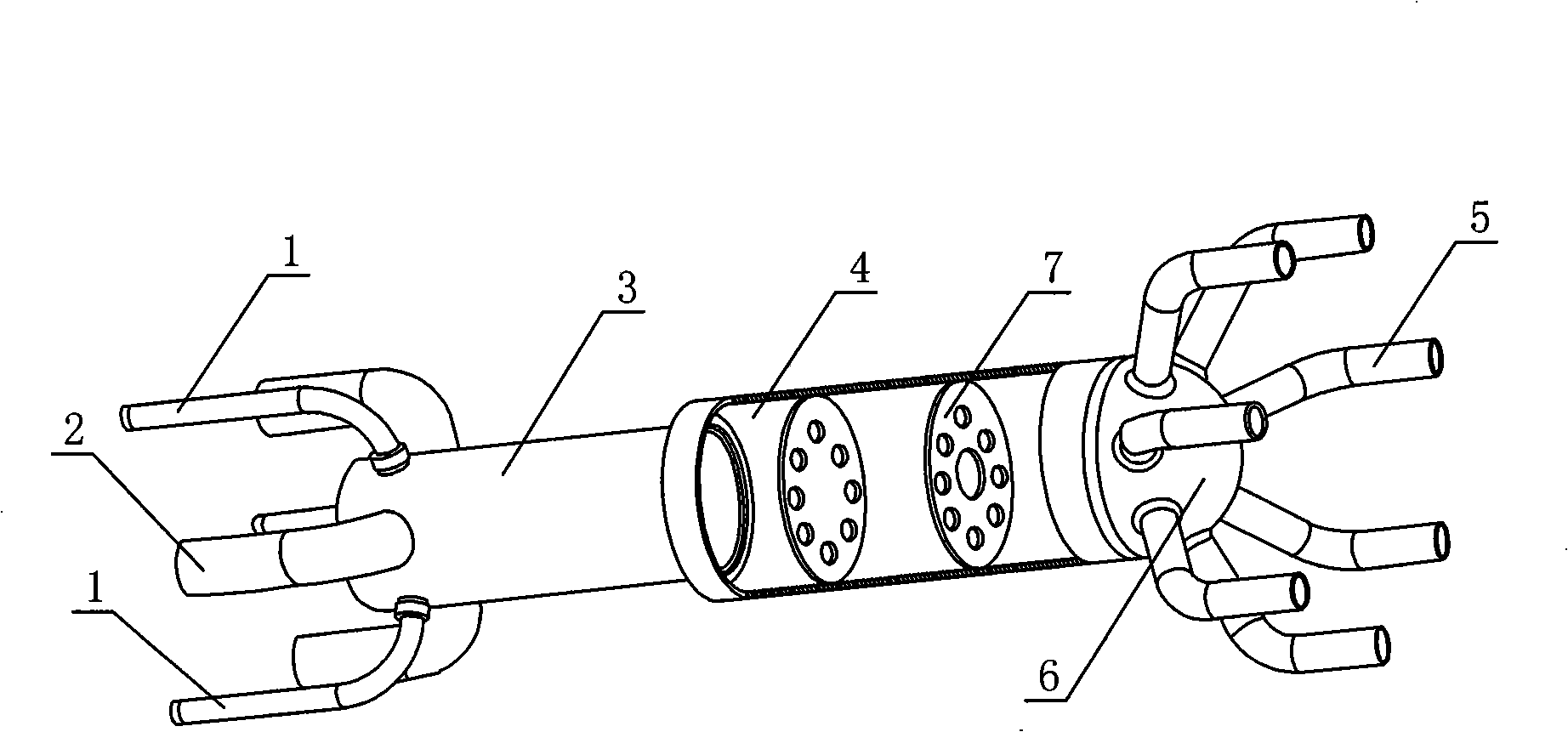

[0014] The temperature field adjustable high-efficiency gas pulsation burner of the present invention is composed of a gas inlet pipe 1, an air inlet pipe 2, a combustion chamber 3, a heat release chamber 4 and a furnace pipe 5, and at least one of the tubular ends of the combustion chamber 3 is arranged and connected alternately The gas inlet pipe 1 of the group and the air inlet pipe 2, the other end of the combustion chamber 3 are connected with the heat release chamber 4, and a plurality of furnace pipes 5 are radially connected on the arc-shaped head 6 of the outlet of the heat release chamber 4.

Embodiment 2

[0016] The high-efficiency gas pulsation burner with adjustable temperature field of the present invention is composed of a gas inlet pipe 1, an air inlet pipe 2, a combustion chamber 3, a heat release chamber 4 and a furnace pipe 5, and five cylindrical ends of the combustion chamber 3 are arranged and connected alternately. Gas inlet pipe 1 and air inlet pipe 2, the other end of combustion chamber 3 are connected with heat release chamber 4, and the cylinder diameter of heat release chamber 4 is greater than the diameter of combustion chamber 3 cylinders. On the arc-shaped sealing head 6 of the outlet of the heat release chamber 4, several supporting furnace tubes 5 are radially connected.

Embodiment 3

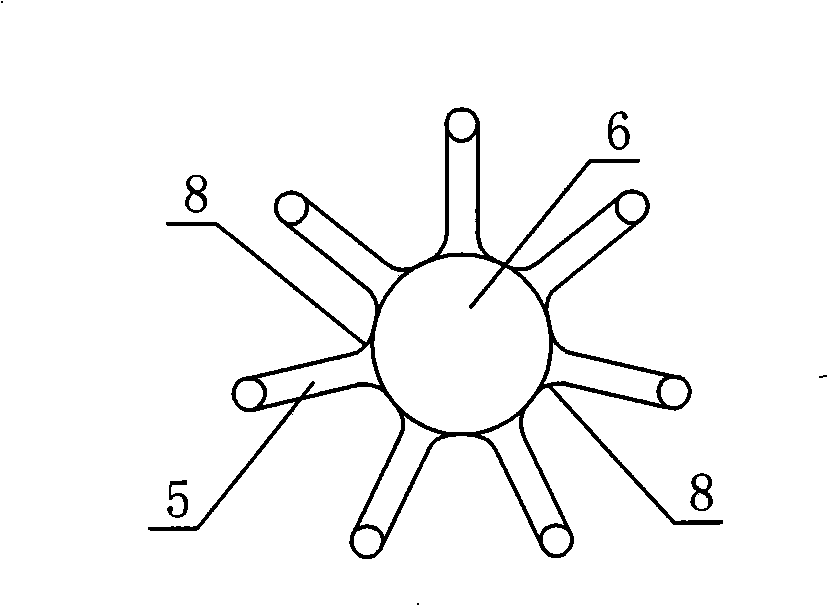

[0018] The high-efficiency gas pulsation burner with adjustable temperature field of the present invention is composed of a gas inlet pipe 1, an air inlet pipe 2, a combustion chamber 3, a heat release chamber 4 and a furnace pipe 5, and three cylindrical ends of the combustion chamber 3 are arranged and connected alternately. Gas inlet pipe 1 and air inlet pipe 2, the other end of combustion chamber 3 are connected with heat release chamber 4, and the cylinder diameter of heat release chamber 4 is greater than the diameter of combustion chamber 3 cylinders. Seven furnace tubes 5 are radially connected to the arc-shaped seal head 6 at the outlet of the heat release chamber 4, and the interface 8 between the seal head 6 and the furnace tube 5 is connected by a curve transition. Two special-shaped deflectors 7 are arranged radially in the heat release chamber 4 . The temperature distribution of the entire pulsating burner can be adjusted and controlled by installing deflectors a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com