Normal Temperature Preservation Method of Caproic Acid Bacteria

A caproic acid bacteria, room temperature technology, applied in the field of microorganisms, can solve problems such as easy damage, high technical equipment requirements, difficult activation, etc., to simplify the experimental operation process, save the passage time, and the experimental operation is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

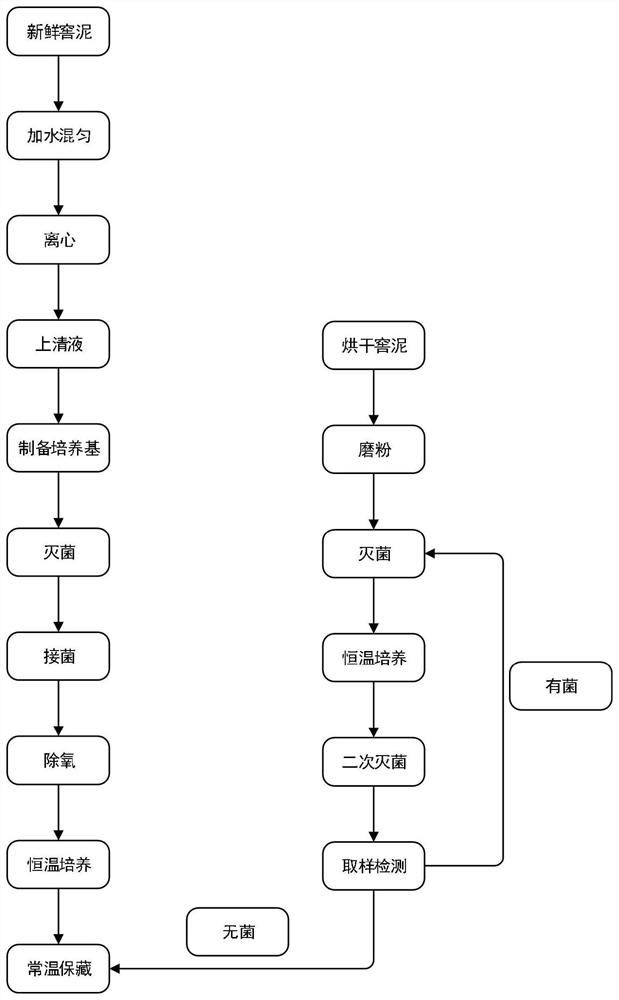

[0038] 1. Take 100g of fresh pit mud, add 500ml of deionized water, mix well, let stand for 2 hours, stir once every half hour, centrifuge at 10000r / min for 10min, absorb the supernatant to obtain the pit mud extract.

[0039] 2. Put the centrifuged pit mud into an oven at 105°C for 6 hours, mechanically grind it through a 100-mesh sieve, pack it in a sealed bag, wrap the outer layer with newspaper, sterilize at 121°C for 30 minutes, take it out and place it in a constant temperature culture at 30°C Place in the box for one day, and then repeat the above operation for secondary sterilization. Take 1g of pit mud and dissolve it in 100ml of distilled water, then absorb 1ml of pit mud aqueous solution and place it on ES solid medium, spread and culture on a petri dish at 34°C for 2 days, no microorganisms grow. Pit mud strain protectant can be used.

[0040] 3. Weigh 0.5g of ammonium sulfate, 5g of sodium acetate, 0.4g of dipotassium hydrogen phosphate, 0.2g of magnesium sulfate,...

Embodiment 2

[0046] 1. Take 100g of fresh pit mud, add 500ml of deionized water, mix well, let stand for 2 hours, stir once every half hour, centrifuge at 10000r / min for 10min, absorb the supernatant to obtain the pit mud extract.

[0047] 2. Put the centrifuged pit mud into an oven at 105°C for 6 hours, mechanically grind it through a 100-mesh sieve, pack it in a sealed bag, wrap the outer layer with newspaper, sterilize at 121°C for 30 minutes, take it out and place it in a constant temperature culture at 30°C Place in the box for one day, and then repeat the above operation for secondary sterilization. Take 1g of pit mud and dissolve it in 100ml of distilled water, then absorb 1ml of pit mud aqueous solution and place it on ES solid medium, spread and culture on a petri dish at 34°C for 2 days, no microorganisms grow. Pit mud strain protectant can be used.

[0048] 3. Weigh 0.5g of ammonium sulfate, 5g of sodium acetate, 0.4g of dipotassium hydrogen phosphate, 0.2g of magnesium sulfate, 1...

Embodiment 3

[0054] 1. Take 100g of fresh pit mud, add 500ml of deionized water, mix well, let stand for 2 hours, stir once every half hour, centrifuge at 10000r / min for 10min, absorb the supernatant to obtain the pit mud extract.

[0055] 2. Put the centrifuged pit mud into an oven at 105°C for 6 hours, mechanically grind it through a 100-mesh sieve, pack it in a sealed bag, wrap the outer layer with newspaper, sterilize at 121°C for 30 minutes, take it out and place it in a constant temperature culture at 30°C Place in the box for one day, and then repeat the above operation for secondary sterilization. Take 1g of pit mud and dissolve it in 100ml of distilled water, then absorb 1ml of pit mud aqueous solution and place it on ES solid medium, spread and culture on a petri dish at 34°C for 2 days, no microorganisms grow. Pit mud strain protectant can be used.

[0056] 3. Weigh 0.5g of ammonium sulfate, 5g of sodium acetate, 0.4g of dipotassium hydrogen phosphate, 0.2g of magnesium sulfate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com